Abstract

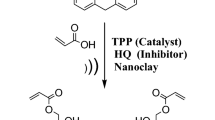

Epoxy/clay nanocomposites modified with carboxyl-terminated poly(butadiene-co-acrylonitrile) (CTBN) liquid rubber (epoxy/clay/CTBN nanocomposites) are synthesized using two different pre-mixing techniques: mechanical high shear mixer (homogenizer) and ultrasonication using tip sonicator. The observations suggest that low molecular weight CTBN easily diffuses into clay galleries, thereby increasing the d-spacing in epoxy/clay/CTBN nanocomposites, regardless of pre-mixing method. High shear mixing causes breaking of clay platelets in epoxy/clay/CTBN nanocomposites, leading to a reduction in the aspect ratio. Epoxy/clay/CTBN nanocomposites prepared via sonication have achieved a uniform and stable morphology, in which the clay platelets are dispersed in epoxy matrix in such a way that most of them try to localize near the phase-separated CTBN domains. Thermal and mechanical properties of the resulting nanocomposites are correlated with morphological findings.

Similar content being viewed by others

References

Chin IJ, Thurn-Albrecht T, Kim HC, Russell TP, Wang J (2001) On exfoliation of montmorillonite in epoxy. Polymer 42:5947–5952. doi:10.1016/S0032-3861(00)00898-3

Osman MA, Mittal V, Morbidelli M, Suter UW (2004) Epoxy-layered silicate nanocomposites and their gas permeation properties. Macromolecules 37:7250–7257. doi:10.1021/ma048798k

Hackman I, Hollaway L (2006) Epoxy-layered silicate nanocomposites in civil engineering. Compos A Appl Sci Manuf 37:1161–1170. doi:10.1016/j.compositesa.2005.05.027

Wang L, Wang K, Chen L, Zhang Y, He C (2006) Preparation, morphology and thermal/mechanical properties of epoxy/nanoclay composite. Compos A Appl Sci Manuf 37:1890–1896. doi:10.1016/j.compositesa.2005.12.020

Ishida H, Campbell S, Blackwell J (2000) General approach to nanocomposites preparation. Chem Mater 12:1260–1267. doi:10.1021/cm990479y

Liu W, Hoa SV, Pugh M (2005) Organoclay-modified high performance epoxy nanocomposites. Compos Sci Tech 65:307–316. doi:10.1016/j.compscitech.2004.07.012

Dalir H, Farahani RD, Nhim V, Samson B, Levesque M, Therriault D (2012) Preparation of highly exfoliated polyester–clay nanocomposites: process–property correlations. Langmuir 28:791–803. doi:10.1021/la203331h

Vijayan PP, Varghese S, Thomas S (2011) Mechanical and viscoelastic characterization of multiphase polymer systems. In: Boudenne A, Ibos L, Candau Y, Thomas S (eds) Handbook of multiphase polymer systems, vol 1. Wiley, Chichester, pp 251–310

Lam C, Lau K, Cheung H, Ling H (2005) Effect of ultrasound sonication in nanoclay clusters of nanoclay/epoxy composites. Mater Lett 59:1369–1372. doi:10.1016/j.matlet.2004.12.048

Dean K, Krstina J, Tian W, Varley RJ (2007) Effect of ultrasonic dispersion methods on thermal and mechanical properties of organoclay epoxy nanocomposites. Macromol Mater Eng 292:415–427. doi:10.1002/mame.200600435

Zunjarrao SC, Sriraman R, Singh RP (2006) Effect of processing parameters and clay volume fraction on the mechanical properties of epoxy–clay nanocomposites. J Mater Sci 41:2219–2228. doi:10.1007/s10853-006-7179-2

Choe CR, Oh CR (1988) Rubber modified epoxies; 1. Effect of CTBN concentration on the mechanical properties. Polymer (Korea) 12:627–633

Wise CW, Cook WD, Goodwin AA (2000) CTBN rubber phase precipitation in model epoxy resins. Polymer 41:4625–4633. doi:10.1016/S0032-3861(99)00686-2

Ozturk A, Kayak C, Tincer T (2001) Effects of liquid rubber modification on the behaviour of epoxy resin. Eur Polym J 37:2353–2363. doi:10.1016/S0014-3057(01)00158-6

Ramos VD, Costa HM, Soares VLP, Nascimento RSV (2005) Modification of epoxy resin: a comparison of different types of elastomer. Polym Test 24:387–394. doi:10.1016/j.polymertesting.2004.09.010

Frohlich J, Thomann R, Mulhaupt R (2003) Toughened epoxy hybrid nanocomposites containing both an organophilic layered silicate filler and a compatibilized liquid rubber. Macromolecules 36:7205–7211. doi:10.1021/ma035004d

Liu W, Hoa SV, Pugh M (2004) Morphology and performance of epoxy nanocomposites modified with organoclay and rubber. Polym Eng Sci 44:1178–1186. doi:10.1002/pen.20111

Lee HB, Kim HG, Yoon KB, Lee DH, Min KE (2009) Preparation and properties of a carboxyl-terminated butadiene acrylonitrile toughened epoxy/montmorillonite nanocomposite. J Appl Polym Sci 113:685–692. doi:10.1002/app.30111

Lee KY, Kim KY, Hwang IR, Choi YS, Hong CH (2010) Thermal, tensile and morphological properties of gamma-ray irradiated epoxy–clay nanocomposites toughened with a liquid rubber. Polym Test 29:139–146. doi:10.1016/j.polymertesting.2009.10.003

Kelnar I, Rotrekl J, Kapralkova L, Hromadkova J, Strachota A (2012) Effect of amine-terminated butadiene–acrylonitrile/clay combinations on the structure and properties of epoxy nanocomposites. J Appl Polym Sci 125:3477–3483. doi:10.1002/app.36696

Chen TH, Zhu JJ, Li BH, Guo SY, Yuan ZY, Sun PC, Ding DT, Shi AC (2005) Exfoliation of organo-clay in telechelic liquid polybutadiene rubber. Macromolecules 38:4030–4033. doi:10.1021/ma047698b

Wang X, Gao Y, Mao K, Xue G, Chen T, Zhu J, Li B, Sun P, Jin Q, Ding D, Shi A (2006) Unusual rheological behavior of liquid polybutadiene rubber/clay nanocomposite gels: the role of polymer–clay interaction, clay exfoliation, and clay orientation and disorientation. Macromolecules 39:6653–6660. doi:10.1021/ma0605494

Pingchuan S, Jianun Z, Tiehong C, Zhongong Y, Baohui L, Qinghua J, Datong D, Anchang S (2004) Rubber/exfoliated–clay nanocomposite gel: direct exfoliation of montmorillonite by telechelic liquid rubber. Chin Sci Bull 49:1664–1666. doi:10.1007/BF03184140

Wang X, Sun P, Xue G, Winter HH (2010) Late-state ripening dynamics of a polymer/clay nanocomposite. Macromolecules 43:1901–1906. doi:10.1021/ma901665m

Sreenivasan P, Ratna D, Albert P, Somashekaran J, Raut R, Chakraborty BC (2013) A new liquid rubber-assisted dispersion of organoclay in carbon black filled carboxylated acrylonitrile–butadiene rubber matrix. J Appl Polym Sci 128:2414–2423. doi:10.1002/app.38256

Vijayan PP, Puglia D, Kenny JM, Thomas S (2013) Effect of organically modified nanoclay on the miscibility, rheology, morphology and properties of epoxy/carboxyl-terminated (butadiene-co-acrylonitrile) blend. Soft Matter 9:2899–2911. doi:10.1039/C2SM27386A

Vijayan PP, Puglia D, Maria HJ, Kenny JM, Thomas S (2013) Clay nanostructure and its localisation in an epoxy/liquid rubber blend. RSC Adv 3:24634–24643. doi:10.1039/c3ra44844d

Miyagawa H, Rich MJ, Drzal LT (2004) Amine-cured epoxy/clay nanocomposites. II. The effect of the nanoclay aspect ratio. J Polym Sci B 42:4391–4400. doi:10.1002/polb.20289

Ray SS (2006) Rheology of polymer/layered silicate nanocomposites. J Ind Eng Chem 12:811–842

Balakrishnan S, Start PR, Raghavan D, Hudson SD (2005) The influence of clay and elastomer concentration on the morphology and fracture energy of preformed acrylic rubber dispersed clay filled epoxy nanocomposites. Polymer 46:11255–11262. doi:10.1016/j.polymer.2005.10.053

Vijayan PP, Puglia D, Jyotishkumar P, Kenny JM, Thomas S (2012) Effect of nanoclay and carboxyl-terminated (butadiene-co-acrylonitrile) (CTBN) rubber on the reaction induced phase separation and cure kinetics of an epoxy/cyclic anhydride system. J Mater Sci 47:5241–5253. doi:10.1007/s10853-012-6409-z

Messersmith PB, Giannelis EP (1994) Synthesis and characterization of layered silicate–epoxy nanocomposites. Chem Mater 6:1719–1725. doi:10.1021/cm00046a026

Lu H, Nutt S (2003) Restricted relaxation in polymer nanocomposites near the glass transition. Macromolecules 36:4010–4016. doi:10.1021/ma034049b

Ingram S, Rhoney I, Liggat JJ, Hudson NE, Pethrick RA (2007) Some factors influencing exfoliation and physical property enhancement in nanoclay epoxy resins based on diglycidyl ethers of bisphenol A and F. J Appl Polym Sci 106:5–19. doi:10.1002/app.25474

Zaman I, Le QH, Kuan HC, Kawashima N, Luong L, Gerson A, Ma J (2011) Interface-tuned epoxy/clay nanocomposites. Polymer 52:497–504. doi:10.1016/j.polymer.2010.12.007

Triantafillidis CS, LeBaron PC, Pinnavaia TJ (2002) Homostructured mixed inorganic–organic ion clays: a new approach to epoxy polymer–exfoliated clay nanocomposites with a reduced organic modifier content. Chem Mater 14:4088–4095. doi:10.1021/cm0202862

Kornmann X, Thomann R, Mulhaupt R, Finter J, Berglund LA (2002) Synthesis of amine-cured, epoxy-layered silicate nanocomposites: the influence of the silicate surface modification on the properties. J Appl Polym Sci 86:2643–2652. doi:10.1002/app.11279

Wang WS, Chen HS, Wu YW, Tsai TY, Chen-Yang YW (2008) Properties of novel epoxy/clay nanocomposites prepared with a reactive phosphorus-containing organoclay. Polymer 49:4826–4836. doi:10.1016/j.polymer.2008.08.019

Verchere D, Sautereau H, Pascault JP, Moschiar SM, Riccardi CC, Williams RJJ (1990) Rubber-modified epoxies. I. Influence of carboxyl-terminated butadiene–acrylonitrile random copolymers (CTBN) on the polymerization and phase separation processes. J Appl Polym Sci 41:467–485. doi:10.1002/app.1990.070410303

Thomas R, Durix S, Sinturel C, Omonov T, Goossens S, Groeninckx G, Moldenaers P, Thomas S (2007) Cure kinetics, morphology and miscibility of modified DGEBA-based epoxy resin—effects of a liquid rubber inclusion. Polymer 48:1695–1710. doi:10.1016/j.polymer.2007.01.018

Thomas R, Yumei D, Yuelong H, Le Y, Moldenaers P, Weimin Y, Czigany T, Thomas S (2008) Miscibility, morphology, thermal, and mechanical properties of a DGEBA based epoxy resin toughened with a liquid rubber. Polymer 49:278–294. doi:10.1016/j.polymer.2007.11.030

Fleming GJ (1966) Mechanisms for initiating thermal degradation of certain anhydride-cured epoxides. J Appl Polym Sci 10:1813–1830. doi:10.1002/app.1966.070101202

Freeman E, Becker AJ (1968) Thermal degradation of nadic methyl anhydride-crosslinked novolac epoxy resin. J Polym Sci A-1 Polym Chem 6:2829–2851. doi:10.1002/pol.1968.150061013

Gac NA, Spokes GN, Benson SW (1970) Thermal degradation of nadic methyl anhydride-cured epoxy novolac. J Polym Sci A-1 Polym Chem 8:593–608. doi:10.1002/pol.1970.150080303

Pionteck J, Muller Y, Hausler L (2011) Reactive epoxy–CTBN rubber blends: reflection of changed curing mechanism in cure shrinkage and phase separation behaviour. Macromol Symp 306–307:126–140. doi:10.1002/masy.201000147

Vijayan PP, Pionteck J, Huczko A, Puglia D, Kenny JM, Thomas S (2014) Liquid rubber and silicon carbide nanofiber modified epoxy nanocomposites: volume shrinkage, cure kinetics and properties. Compos Sci Tech 102:65–73. doi:10.1016/j.compscitech.2014.07.017

Tripathi G, Srivastava D (2008) Studies on the physico-mechanical and thermal characteristics of blends of DGEBA epoxy, 3,4 epoxy cyclohexylmethyl, 3′,4′-epoxycylohexane carboxylate and carboxyl terminated butadiene co-acrylonitrile (CTBN). Mater Sci Eng A 496:483–493. doi:10.1016/j.msea.2008.06.035

Chen WS, Chang YL, Hsiang HI, Hsu FC, Shen YH, Yen FS (2011) Mechanical and dielectric properties of NiZn ferrite powders–CTBN modified epoxy resin coatings. Polym Plast Technol Eng 50:568–572. doi:10.1080/03602559.2010.543737

Ray SS, Okamoto M (2003) Polymer/layered silicate nanocomposites: a review from preparation to processing. Prog Polym Sci 28:1539–1641. doi:10.1016/j.progpolymsci.2003.08.002

Lakshmi MS, Narmadha B, Reddy BSR (2008) Enhanced thermal stability and structural characteristics of different MMT–Clay/epoxy-nanocomposite materials. Polym Degrad Stab 93:201–213. doi:10.1016/j.polymdegradstab.2007.10.005

Jan IN, Lee TM, Chiou KC, Lin JJ (2005) Comparisons of physical properties of intercalated and exfoliated clay/epoxy nanocomposites. Ind Eng Chem Res 44:2086–2090. doi:10.1021/ie048934+

Camino G, Tartaglione G, Frache A, Manferti C, Costa G (2005) Thermal and combustion behaviour of layered silicate–epoxy nanocomposites. Polym Degrad Stab 90:354–362. doi:10.1016/j.polymdegradstab.2005.02.022

Katsoulis C, Kandare E, Kandola BK (2011) The effect of nanoparticles on structural morphology, thermal and flammability properties of two epoxy resins with different functionalities. Polym Degrad Stab 96:529–540. doi:10.1016/j.polymdegradstab.2011.01.002

Ratna D (2001) Phase separation in liquid rubber modified epoxy mixture. Relationship between curing conditions, morphology and ultimate behaviour. Polymer 42:4209–4218. doi:10.1016/S0032-3861(00)00798-9

Tripathi G, Srivastava D (2007) Effect of carboxyl-terminated poly(butadiene-co-acrylonitrile) (CTBN) concentration on thermal and mechanical properties of binary blends of diglycidyl ether of bisphenol-A (DGEBA) epoxy resin. Mater Sci Eng A 443:262–269. doi:10.1016/j.msea.2006.09.031

Yasmin A, Luo JJ, Abot JL, Daniel IM (2006) Mechanical and thermal behavior of clay/epoxy nanocomposites. Compos Sci Tech 66:2415–2422. doi:10.1016/j.compscitech.2006.03.011

Siddiqui NA, Woo RSC, Kim JK, Leung CCK, Munir A (2007) Corrigendum to “Mode I interlaminar fracture behaviour and mechanical properties of CFRPs with nanoclay-filled epoxy matrix”. Compos A 38:449–460. doi:10.1016/j.compositesa.2006.12.002

Isik I, Yilmazer U, Bayram G (2003) Impact modified epoxy/montmorillonite nanocomposites: synthesis and characterization. Polymer 44:6371–6377. doi:10.1016/S0032-3861(03)00634-7

Zilg C, Thomann R, Finter J, Mulhaupt R (2000) The influence of silicate modification and compatibilizers on mechanical properties and morphology of anhydride-cured epoxy nanocomposites. Macromol Mater Eng 280–281:41–46. doi:10.1002/1439-2054(20000801)280:1<41:AID-MAME41>3.0.CO;2-Z

Kinloch AJ, Shaw SJ, Tod DA, Hunston DL (1983) Deformation and fracture behaviour of a rubber-toughened epoxy: 1. Microstructure and fracture studies. Polymer 24:1341–1354. doi:10.1016/0032-3861(83)90070-8

Kinloch AJ, Shaw SJ, Hunston DL (1983) Deformation and fracture behaviour of a rubber-toughened epoxy: 2. Failure criteria. Polymer 24:1355–1363. doi:10.1016/0032-3861(83)90071-X

Yee AF, Pearson RA (1986) Toughening mechanisms in elastomer-modified epoxies. J Mater Sci 21:2462–2474. doi:10.1007/BF01114294

Lan T, Pinnavaia TJ (1994) Clay–reinforced epoxy nanocomposites. Chem Mater 6:2216–2219. doi:10.1021/cm00048a006

Mullins MJ, Liu D, Sue H-J (2012) Mechanical properties of thermosets. In: Guo Q (ed) Thermosets: structure properties and applications. Woodhead, UK, pp 28–61

Acknowledgments

The authors would like to thank CSIR (New Delhi) for the financial support and Huntsmann for their kind supply of chemicals for the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vijayan, P.P., Puglia, D., Pionteck, J. et al. Liquid-rubber-modified epoxy/clay nanocomposites: effect of dispersion methods on morphology and ultimate properties. Polym. Bull. 72, 1703–1722 (2015). https://doi.org/10.1007/s00289-015-1365-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-015-1365-9