Abstract

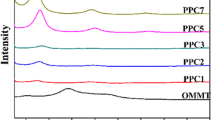

The current manuscript describes the effects of two different processing conditions on the barrier properties of HDPE/MMT nanocomposites. It is well known that the exfoliation degree of the primary clay mineral determines the gas permeation properties of the final composite. The tortuosity effect caused by the dispersed nanolayers improve the gas barrier properties in some cases while in other cases the interfacial regions or the free volume variations may overcome the tortuosity impact reducing the barrier effectiveness. In the present work, twenty MMT-HDPE nanocomposites were obtained using two types of commercial clay, two compatibilizers, and two different processing methods. The exfoliation and agglomeration of the nanocomposites were investigated by WAXD and TEM. Their gas permeability was measured as a function of the filler loading and was correlated to their impermeable inorganic volume fraction. The oxygen permeability of the nanocomposites decreased as much as 40 % when compared to the pure HDPE.

Similar content being viewed by others

References

Jordan J, Jacob KI, Tannenbaumc R, Sharafb MA, Jasiukd I (2005) Experimental trends in polymer-matrix nanocomposites—a review. Mater Sci Eng 393(A):1–11

Picard E, Vermogen A, Gerard JF, Espuche E (2007) Barrier properties of nylon 6-montmorillonite nanocomposite membranes prepared by melt blending: influence of the clay content and dispersion state. Consequences on modelling. J Membr Sci 292(1–2):133–144

Osman MA, Rupp JEP, Suter UW (2005) Gas permeation properties of polyethylene-layered silicate nanocomposites. J Mater Chem 15(12):1298–1304

Yang Y, Chen J, Yuan Q, Misra RDK (2011) Structure–property relationship in impact modified nanoclay-reinforced polypropylene. Mater Sci Eng A Struct Mater Prop Microstruct Process 528(3):1857–1863

Ray SS, Okamoto M (2003) Polymer/layered silicate nanocomposites: a review from preparation to processing. Prog Polym Sci 28(11):1539–1641

Bharadwaj RK (2001) Modeling the barrier properties of polymer-layered silicate nanocomposites. Macromolecules 34(26):9189–9192

Ghasemi H (2012) Properties of PET/clay nanocomposite films. Polym Eng Sci 52(2):420–430

Dennis H, Hunter D, Chang D, Kim S, White J, Cho J, Paul D (2001) Effect of melt processing conditions on the extent of exfoliation in organoclay-based nanocomposites. Polymer 42(23):9513–9522

Sperling LH (2006) Introduction to physical polymer science. Wiley, New York

Kessner U, Kaschta J, Stadler FJ, Duff CSL, Drooghaag X, Münstedt H (2010) Thermorheological behavior of various short- and long-chain branched polyethylenes and their correlations with the molecular structure. Macromolecules 43:7341–7350

Zuilichem DV, Stolp W, Janssen L (1983) Engineering aspects of single-and twin -screw extrusion-cooking of biopolymers. J Food Eng 2:157–175

Schmidt G, Malwitz MM (2003) Properties of polymer–nanoparticle composites. Curr Opin Colloid Interface Sci 8:103–108

Lin-Gibson S, Schmidt G, Kim H, Han C, Hobbie K (2003) Shear-induced mesostructures in nanoplatelet–polymer networks. J Chem Phys 119(15):119

Brown ABD, Rennie AR (2001) Images of shear-induced phase separation in a dispersion of hard nanoscale discs. Chem Eng Sci 56:2999–3004

Alavi R, Angaji T, Gholami MZ (2009) Twin- screw extruder and effective parameters on the HDPE extrusion process. World Acad Sci Eng Technol 37:204–207

Wang ZF, Wang B, Qi N, Zhang HF, Zhang LQ (2004) Influence of fillers on free volume and gas barrier properties in styrene-butadiene rubber studied by positrons. Polymer 46(3):719–724

Linjie Z, Xanthos M (2004) Effects of process conditions and mixing protocols on structure of extruded polypropylene nanocomposites. J Appl Polym Sci 93(4):1891–1899

Ogah AO, Afiukwa JN (2012) The effects of linear low-density polyethylene (LLDPE) on he mechanical properties of high-density polyethylene (HDPE) film blends. Int J Eng Manag Sci 3(2):85–90

Soney GC, Thomas S (2001) Transport phenomena through polymeric systems. Prog Polym Sci 26:985–1017

Xu B, Zheng Q, Song Y, Shangguan Y (2006) Calculating barrier properties of polymer/clay nanocomposites: effects of clay layers. Polymer 47(8):2905–2910

Acknowledgments

The authors wish to thank CONACYT for its financial support to carry out this study through Project 84424. In addition, one of the authors AMB wishes to thank CONACYT for its support to carry out her MSc studies. Finally, the authors wish to thank M. Sánchez-Adame, M.C. Gonzalez-Cantu, T. Rodriguez-Hernandez, B. Huerta-Martinez, J. Rodriguez-Velazquez, J.F. Zendejo, E. Hurtado-Suarez, and P. Siller-Flores for their valuable technical and informatics support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Monsiváis-Barrón, A.J., Bonilla-Rios, J., Ramos de Valle, L.F. et al. Oxygen permeation properties of HDPE-layered silicate nanocomposites. Polym. Bull. 70, 939–951 (2013). https://doi.org/10.1007/s00289-012-0897-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-012-0897-5