Abstract

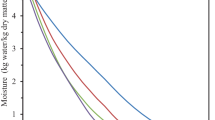

Infrared-vacuum drying characteristics of button mushroom (Agaricus bisporus) were evaluated in a combined dryer system. The effects of drying parameters, including infrared radiation power (150–375 W), system pressure (5–15 kPa) and time (0–160 min) on the drying kinetics and characteristics of button mushroom slices were investigated. Both the infrared lamp power and vacuum pressure influenced the drying time of button mushroom slices. The rate constants of the nine different kinetic’s models for thin layer drying were established by nonlinear regression analysis of the experimental data which were found to be affected mainly by the infrared power level while system pressure had a little effect on the moisture ratios. The regression results showed that the Page model satisfactorily described the drying behavior of button mushroom slices with highest R value and lowest SE values. The effective moisture diffusivity increases as power increases and range between 0.83 and 2.33 × 10−9 m2/s. The rise in infrared power has a negative effect on the ΔE and with increasing in infrared radiation power it was increased.

Similar content being viewed by others

Abbreviations

- a:

-

Redness/greenness that ranges from −120 to 120

- b:

-

Yellowness/blueness that ranges from −120 to 120

- Deff :

-

Effective diffusivity (m2/s)

- D0 :

-

Pre-exponential factor (m2/s)

- L:

-

Half slab thickness of the slices (m)

- K:

-

Slope

- k:

-

Drying rate constants in models (1/s)

- L:

-

Lightness/darkness that ranges from 0 to 100

- MR:

-

Dimensionless moisture ratio

- Mt :

-

Moisture content at time t (kg water/kg dry matter)

- Me:

-

Equilibrium moisture content (kg water/kg dry matter)

- M0 :

-

Initial moisture content (kg water/kg dry matter)

- N:

-

Number of observations

- n:

-

Number of constants

- R:

-

Correlation coefficient

- t:

-

Drying time (min)

- ∆a:

-

a2 − a1 (redness/greenness)

- ∆b:

-

b2 − b1 (yellowness/blueness)

- ∆E:

-

Color changes

- ∆L:

-

L2 − L1 (lightness/darkness)

References

Giri S, Prasad S (2007) Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. J Food Eng 78:512–521

Salehi F, Kashaninejad M, Asadi F, Najafi A (2016) Improvement of quality attributes of sponge cake using infrared dried button mushroom. J Food Sci Technol 53:1418–1423. doi:10.1007/s13197-015-2165-9

Santos MV, Lespinard AR (2011) Numerical simulation of mushrooms during freezing using the FEM and an enthalpy: Kirchhoff formulation. Heat Mass Transfer 47:1671–1683. doi:10.1007/s00231-011-0831-7

Ghanbarian D, Baraani Dastjerdi M, Torki-Harchegani M (2016) Mass transfer characteristics of bisporus mushroom (Agaricus bisporus) slices during convective hot air drying. Heat Mass Transf 52:1081–1088. doi:10.1007/s00231-015-1629-9

Mathlouthi M (2001) Water content, water activity, water structure and the stability of foodstuffs. Food Control 12:409–417

Salehi F, Kashaninejad M, Akbari E, Sobhani SM, Asadi F (2016) Potential of sponge cake making using infrared-hot air dried carrot. J Texture Stud 47:34–39. doi:10.1111/jtxs.12165

Lozano J, Rotstein E, Urbicain M (1983) Shrinkage, porosity and bulk density of foodstuffs at changing moisture contents. J Food Sci 48:1497–1502

Shrivastava M, Datta A (1999) Determination of specific heat and thermal conductivity of mushrooms (Pleurotus florida). J Food Eng 39:255–260

Allanic N, Le Bideau P, Glouannec P, Deterre R (2016) An experimental study on infrared drying kinetics of an aqueous adhesive supported by polymer composite. Heat Mass Transf. doi:10.1007/s00231-016-1816-3

Sandu C (1986) Infrared radiative drying in food engineering: a process analysis. Biotechnol Progr 2:109–119

Sadin R, Chegini G-R, Sadin H (2014) The effect of temperature and slice thickness on drying kinetics tomato in the infrared dryer. Heat Mass Transf 50:501–507. doi:10.1007/s00231-013-1255-3

Sakai N, Hanzawa T (1994) Applications and advances in far-infrared heating in Japan. Trends Food Sci Technol 5:357–362

Ratti C, Mujumdar A (1995) Infrared drying. In: Mujumdar AS (ed) Handbook of industrial drying, vol 1, 2nd edn. Marcel Dekker Inc, New York, pp 567–588

Nowak D, Lewicki PP (2004) Infrared drying of apple slices. Innov Food Sci Emerg Technol 5:353–360

H-c Wang, Zhang M, Adhikari B (2015) Drying of shiitake mushroom by combining freeze-drying and mid-infrared radiation. Food Bioprod Process 94:507–517

Nawirska A, Figiel A, Kucharska AZ, Sokół-Łętowska A, Biesiada A (2009) Drying kinetics and quality parameters of pumpkin slices dehydrated using different methods. J Food Eng 94:14–20

McLoughlin C, McMinn W, Magee T (2003) Microwave-vacuum drying of pharmaceutical powders. Dry Technol 21:1719–1733

Pan Z, Shih C, McHugh TH, Hirschberg E (2008) Study of banana dehydration using sequential infrared radiation heating and freeze-drying. LWT-Food Sci Technol 41:1944–1951

Arora S, Shivhare U, Ahmed J, Raghavan G (2003) Drying kinetics of Agaricus bisporus and Pleurotus florida mushrooms. Trans Am Soc Agric Eng 46:721–724

Rhim J-W, Lee JH (2011) Drying kinetics of whole and sliced shiitake mushrooms (Lentinus edodes). Food Sci Biotechnol 20:419–427

Xanthopoulos G, Lambrinos G, Manolopoulou H (2007) Evaluation of thin-layer models for mushroom (Agaricus bisporus) drying. Dry Technol 25:1471–1481

Artnaseaw A, Theerakulpisut S, Benjapiyaporn C (2010) Drying characteristics of Shiitake mushroom and Jinda chili during vacuum heat pump drying. Food Bioprod Process 88:105–114

Ebrahim RM, Kashaninezhad M, Mirzaei HE, Khomeiri M (2009) Effect of temperature, osmotic solution concentration and mass ratio on kinetics of osmotic dehydration of button mushroom (Agaricus bisporus). J Agric Sci Nat Resour 16(1):1–10

Arumuganathan T, Manikantan M, Rai R, Anandakumar S, Khare V (2009) Mathematical modeling of drying kinetics of milky mushroom in a fluidized bed dryer. Int Agrophys 23:1–7

Darvishi H, Najafi G, Hosainpour A, Khodaei J, Aazdbakht M (2013) Far-infrared drying characteristics of mushroom slices. Chem Prod Process Model 8:107–117

Rodríguez R, Lombrana J, Kamel M, De Elvira C (2005) Kinetic and quality study of mushroom drying under microwave and vacuum. Dry Technol 23:2197–2213

Torringa E, Esveld E, Scheewe I, van den Berg R, Bartels P (2001) Osmotic dehydration as a pre-treatment before combined microwave-hot-air drying of mushrooms. J Food Eng 49:185–191

Doymaz I (2011) Drying of eggplant slices in thin layers at different air temperatures. J Food Process Preserv 35:280–289

Ceylan I, Aktaş M, Doğan H (2007) Mathematical modeling of drying characteristics of tropical fruits. Appl Therm Eng 27:1931–1936

Akpinar EK, Bicer Y (2005) Modelling of the drying of eggplants in thin-layers. Int J Food Sci Technol 40:273–281

Sacilik K (2007) Effect of drying methods on thin-layer drying characteristics of hull-less seed pumpkin (Cucurbita pepo L.). J Food Eng 79:23–30

Salehi F, Kashaninejad M (2015) Effect of drying methods on rheological and textural properties, and color changes of wild sage seed gum. J Food Sci Technol 52:7361–7368. doi:10.1007/s13197-015-1849-5

Salehi F, Kashaninejad M (2014) Effect of different drying methods on rheological and textural properties of Balangu seed gum. Dry Technol 32:720–727

Khanali M, Banisharif A, Rafiee S (2016) Modeling of moisture diffusivity, activation energy and energy consumption in fluidized bed drying of rough rice. Heat Mass Transfer. doi:10.1007/s00231-016-1763-z

Lutovska M, Mitrevski V, Pavkov I, Mijakovski V, Radojčin M (2016) Mathematical modelling of thin layer drying of pear. Chem Ind Chem Eng Q 22(2):191–199

Lampinen MJ, Ojala KT, Koski E (1991) Modeling and measurements of infrared dryers for coated paper. Dry Technol 9:973–1017

Walde S, Velu V, Jyothirmayi T, Math R (2006) Effects of pretreatments and drying methods on dehydration of mushroom. J Food Eng 74:108–115

Masamura A, Sado H, Honda T, Shimizu M, Nabetani H, Nakajima M, Watanabe A (1988) Drying of potato by far infrared radiation. J Jpn Soc Food Sci Technol (Japan) 35(5):309–314

Datta A, Ni H (2002) Infrared and hot-air-assisted microwave heating of foods for control of surface moisture. J Food Eng 51:355–364

Arévalo-Pinedo A, Murr FEX (2007) Influence of pre-treatments on the drying kinetics during vacuum drying of carrot and pumpkin. J Food Eng 80:152–156

Toğrul H (2006) Suitable drying model for infrared drying of carrot. J Food Eng 77:610–619

Mongpraneet S, Abe T, Tsurusaki T (2002) Far infrared–vacuum and–convection drying of welsh onion. Trans ASAE 45:1529

Rizvi SS (1986) Thermodynamic properties of foods in dehydration. Eng Prop Foods 2:239–251

Zielinska M, Markowski M (2007) Drying behavior of carrots dried in a spout–fluidized bed dryer. Dry Technol 25:261–270

Simal S, Femenia A, Garau M, Rosselló C (2005) Use of exponential, Page’s and diffusional models to simulate the drying kinetics of kiwi fruit. J Food Eng 66:323–328

Vega A, Fito P, Andrés A, Lemus R (2007) Mathematical modeling of hot-air drying kinetics of red bell pepper (var. Lamuyo). J Food Eng 79:1460–1466

Shiby V, Mishra H (2007) Thin layer modelling of recirculatory convective air drying of curd (Indian yoghurt). Food Bioprod Process 85:193–201

Doymaz İ (2005) Drying characteristics and kinetics of okra. J Food Eng 69:275–279

Nimmol C (2010) Vacuum far-infrared drying of foods and agricultural materials. J King Mongkut’s Univ Technol N Bangk 20:37–44

Swasdisevi T, Devahastin S, Ngamchum R, Soponronnarit S (2007) Optimization of a drying process using infrared-vacuum drying of Cavendish banana slices. Optimization 29:810

Guiné RP, Barroca MJ (2012) Effect of drying treatments on texture and color of vegetables (pumpkin and green pepper). Food Bioprod Process 90:58–63

Therdthai N, Zhou W (2009) Characterization of microwave vacuum drying and hot air drying of mint leaves (Mentha cordifolia Opiz ex Fresen). J Food Eng 91:482–489

Acknowledgements

This research was supported by Iran National Science Foundation (INSF) through a Grant No. 92044245 to Mahdi Kashaninejad. The authors would like to thank gratefully Iran National Science Foundation, INSF, for financial support of the research project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Salehi, F., Kashaninejad, M. & Jafarianlari, A. Drying kinetics and characteristics of combined infrared-vacuum drying of button mushroom slices. Heat Mass Transfer 53, 1751–1759 (2017). https://doi.org/10.1007/s00231-016-1931-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1931-1