Abstract

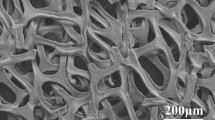

The present article reports on a detailed experimental investigation of using carbon foam–PCM–MWCNTs composite materials for thermal management (TM) of electronic devices subjected to pulsed power. The TM module was fabricated by infiltrating paraffin wax (RT65) as a phase change material (PCM) and multi walled carbon nanotubes (MWCNTs) as a thermal conductivity enhancer in a carbon foam as a base structure. Two carbon foam materials of low and high values of thermal conductivities, CF20 and KL1-250 (3.1 and 40 W/m K), were tested as a base structure for the TM modules. Tests were conducted at different power intensities and power cycling/loading modes. Results showed that for all power varying modes and all carbon foams, the infiltration of RT65 into carbon foam reduces the temperature of TM module and results in damping the temperature spikes height. Infiltration of MWCNTS into RT65 further improves the effectiveness of TM module. Temperature damping was more pronounced in stand-alone pulsed power cycles as compared to pulsed power spikes modes. The effectiveness of inclusion of RT65 and RT65/MWCNTs in damping the temperature spikes height is remarkable in TM modules based on KL1-250 as compared to CF-20.

Similar content being viewed by others

References

Viswanath R, Wakharkar V, Watwe A, Lebonheur V (2000) Thermal performance challenges from silicon to systems. Intel Technol J 4:1

Bar-Cohen A, Kraus AD (1983) Thermal analysis and control of electronic equipment, chap 1, 4, 9. Hemisphere Publishing, USA

Py X, Olives R, Mauran S (2001) Paraffin/porous graphite-matrix composite as a high and constant power thermal storage material. Int J Heat Mass Transf 44:2727–2737

O’Conner JP, Weber RM (1997) Thermal management of electronic packages using solid-to-liquid phase change techniques. Int J Microcircuit Electron Packag 20:593–601

Pal D, Yoshi YK (1999) Thermal control of horizontally mounted heat sources using phase change material. In: Proceedings of the Pacific Rim/ASME international intersociety electronic and photonic packaging conference (InterPACK‘99), vol 2, Maui, Hawaii, pp 1625–1630

Clarksean R, Chen Y, Marongiu M (1999) An analysis of heat flux limits for electronic components on a finned substrate containing a PCM. In: Proceedings of the Pacific Rim/ASMEb international intersociety electronic and photonic packaging conference (InterPACK‘99), vol 2, Maui, Hawaii, pp 1611–1616

Clarksean R, Chen Y (1999) The use of phase change material for electronic cooling application: thermal design issues and example. In: Proceedings of the Pacific Rim/ASME international intersociety electronic and photonic packaging conference (InterPACK‘99), vol 2, Maui, Hawaii, pp 1631–1640

Pal D, Joshi Y (1997) Application of phase change materials to thermal control of electronic modules: a computational study. J Electron Packag 119:40–50

Vesligaj MJ, Amon CH (1999) Transient thermal management of temperature fluctuations during time varying workloads on portable electronics. IEEE Trans Compon Packag Technol 22:541–550

Krishnan S, Garimella SV (2004) Analysis of a phase change energy storage system for pulsed power dissipation. IEEE Trans Compon Packag Technol 271:191–199

Krishnan S, Garimella SV (2004) Thermal management of transient power spikes in electronics, phase change energy storage or copper heat sinks. ASME J Electron Packag 126(3):308–316

Kandasamy R, Wang X-Q, Mujumdar AS (2008) Transient cooling of electronics using phase change material (PCM)-based heat sinks. Appl Therm Eng 28:1047–1057

Stupar A, Drofenik U, Kolar JW (2010) Application of phase change materials for low duty cycle high peak load power supplies. CIPS, 16–18, Germany

El Omari K, Kousksou T, Le Guer Y (2011) Impact of shape of container on natural convection and melting inside enclosures used for passive cooling of electronic devices. Appl Therm Eng 31:3022–3035

Mallik S, Ekere N, Best C, Bhatti R (2011) Investigation of thermal management materials for automotive electronic control units. Appl Therm Eng 31:355–362

Wang Y-H, Yang Y-T (2011) Three-dimensional transient cooling simulations of a portable electronic device using PCM (phase change materials) in multi-fin heat sink. Energy 36:5214–5224

Shaikh S, Lafdi K (2010) C/C composite, carbon nanotube and paraffin wax hybrid systems for the thermal control of pulsed power in electronics. Carbon 48:813–824

Alshaer WG, Nada SA, Rady MA, Le Bot C, Palomo Del Barrio E (2014) Numerical investigations of using carbon foam/PCM/Nano carbon tubes composites in thermal management of electronic equipment. Energy Convers Manag 89:873–884

Nada SA, Alshaer WG (2015) Comprehensive parametric study of using carbon foam structures saturated with PCMs in thermal management of electronic systems. Energy Convers Manag 105:93–102

Canseco V, Anguy Y, Roa JJ, Palomo E (2014) Structural and mechanical characterization of graphite foam/phase change material composites. Carbon 74:266–281

Alshaer WG, Palomo del Barrio E, Rady MA, Abdellatif OE, Nada SA (2013) Analysis of the anomalous thermal properties of phase change materials based on paraffin wax and multi walls carbon nanotubes. Int J Heat Mass Transf Theory Appl 1(5)

Shaikh S, Lafdi K, Hallinan K (2008) Carbon Nano additives to enhance latent energy storage of phase change materials. J Appl Phys 103(9). Article ID 094302

Acknowledgments

This work was supported by the French government via the cultural section of the French Embassy in Egypt and the Institut de Mécanique et d’Ingénierie—Bordeaux-France.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alshaer, W.G., Rady, M.A., Nada, S.A. et al. An experimental investigation of using carbon foam–PCM–MWCNTs composite materials for thermal management of electronic devices under pulsed power modes. Heat Mass Transfer 53, 569–579 (2017). https://doi.org/10.1007/s00231-016-1815-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1815-4