Abstract

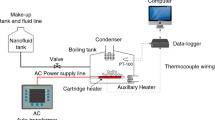

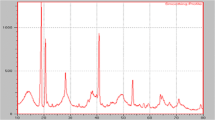

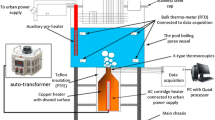

A set of experiments was performed to quantify the pool boiling heat transfer coefficient of water/γ-alumina micro-fluids at mass concentration ranged from 0.1 to 0.4 % of micro-particles with mean size of 1–2 μm. To stabilize the prepared micro-fluid, pH control, stirring and adding the SDS as a surfactant were carried out. Also, thermal conductivity of micro-fluids are measured using KD2 decagon pro. Results showed that micro-fluids have relatively higher thermal conductivity rather than the base fluids. According to the results, there are two distinguishable heat transfer regions namely natural convection and nucleate boiling regions. Influence of some operating parameters such as heat flux, mass concentration of micro-particles and surface fouling resistance on the pool boiling heat transfer coefficient were experimentally studied and briefly discussed. Results demonstrated a significant deterioration of heat transfer coefficient of micro-fluids in comparison with the base fluid over the extended time (1000 min of operation) in nucleate boiling region, while in natural convection region, enhancement of heat transfer coefficient is registered. According to the results, heat transfer coefficient is strongly controlled by/γ-alumina concentration due to the deposition of micro-particles on the heating section. Rectilinear changes of scale formation with time in term of fouling resistance were clearly seen at regions, where natural convection is a dominant heat transfer mechanism and also for higher heat fluxes at nucleate boiling heat transfer region.

Similar content being viewed by others

Abbreviations

- A :

-

Area (m2)

- b :

-

Distance (m)

- I :

-

Current (A)

- k :

-

Thermal conductivity (W m−1 K−1)

- L :

-

Length (m)

- m f :

-

Mass of deposition (kg s−1)

- Q :

-

Heat (W)

- q′′ :

-

Heat flux (W m−2)

- R :

-

Roughness (m)

- R f :

-

Fouling resistance (m2 K kW−1)

- S :

-

Distance between thermometer location and heat transfer surface (m)

- T :

-

Temperature (K)

- t :

-

Time (min)

- V :

-

Voltage (v)

- b :

-

Bulk

- th :

-

Thermometers

- w :

-

Wall

- Ave:

-

Average

- HTC:

-

Heat transfer coefficient

- Min:

-

Minutes

- Max:

-

Maximum

- RPM:

-

Revolutions per minutes

- α :

-

Heat transfer coefficient (W m−2 K−1)

- Δ:

-

Difference

References

Barber J, Brutin D, Tadrist L (2011) A review on boiling heat transfer enhancement with nanofluids. Nanoscale Res Lett 6:280

Choi S (1995) Enhancing thermal conductivity of fluids with nanoparticles. In: Proceedings of the 1995 ASME international mechanical engineering congress and exposition, San Francisco, CA, USA

Yu W, France D, Routbort J, Choi S (2008) Review and comparison of nanofluid thermal conductivity and heat transfer enhancements. Heat Trans Eng 29(5):432–460

Lee JK, Hwang YJ, Ahn YC, Shin HS, Lee CG, Kim GT, Park HS (2006) Investigation on characteristics of thermal conductivity enhancement of nanofluids. Curr Appl Phys 6:1068–1071

Faulkner D, Khotan M, Shekarriz R (2003) Practical design of a 1000 W/cm2 cooling system (high power electronics). In: Semiconductor thermal measurement and management symposium (nineteenth annual IEEE), pp 223–230

Peyghambarzadeh SM, Vatani A, Jamialahmadi M (2013) Influences of bubble formation on different types of heat exchanger fouling. Appl Therm Eng 50:848–856

Pan Y, Si F, Zhigao X, Romero C, Qiao Z, Ye Y (2012) DEM simulation and fractal analysis of particulate fouling on coal-fired utility boilers’ heating surfaces. Powder Technol 231:70–76

Das SK, Putra N, Roetzel W (2003) Pool boiling characteristics of nano-fluids. Int J Heat Mass Transf 46(5):851–862

Zhang G, Li G, Li W, Zhang Z, Leng X, Tian M (2013) Particulate fouling and composite fouling assessment in corrugated plate heat exchangers. Int J Heat Mass Transf 60:263–273

Peyghambarzadeh SM, Vatani A, Jamialahmadi M (2012) Application of asymptotic model for the prediction of fouling rate of calcium sulfate under subcooled flow boiling. Appl Therm Eng 39:105–113

Peyghambarzadeh SM, Bahrami N (2013) Statistical analysis of calcium sulfate scaling under boiling heat transfer. Appl Therm Eng 53:108–113

Nikkhah V, Sarafraz MM, Hormozi F, Peyghambarzadeh SM (2015) Particulate fouling of CuO–water nanofluid at isothermal diffusive condition inside the conventional heat exchanger-experimental and modeling. Exp Therm Fluid Sci 60:83–95

Sarafraz MM, Hormozi F (2014) Nucleate pool boiling heat transfer characteristics of dilute Al2O3–ethyleneglycol nanofluids. Int Commun Heat Mass Transf 58:96–104

Sarafraz MM, Hormozi F (2014) Scale formation and sub-cooled flow boiling heat transfer of CuO–water nanofluid inside the vertical annulus. Exp Therm Fluid Sci 52:205–214

Sarafraz MM, Hormozi F (2014) Convective boiling and particulate fouling of stabilized CuO–ethylene glycol nanofluids inside the annular heat exchanger. Int Commun Heat Mass Transf 53:116–123

Sarafraz MM, Hormozi F, Kamalgharibi M (2014) Sedimentation and convective boiling heat transfer of CuO–water/ethylene glycol nanofluids. Heat Mass Transf J 50:1237–1249

Sarafraz MM, Peyghambarzadeh SM, Alavi Fazel SA, Vaeli N (2012) Nucleate pool boiling heat transfer of binary nano mixtures under atmospheric pressure around a smooth horizontal cylinder. Period Polytech Chem Eng 56(2):1–7

Sarafraz MM, Pyghambarzadeh SM (2012) Nucleate pool boiling heat transfer to Al2O3–water and TiO2–water nanofluids on horizontal smooth tubes with dissimilar homogeneous materials. Chem Biochem Eng Q 26(3):199–206

Raveshi MR, Keshavarz A, Mojarrad MS, Amiri S (2013) Experimental investigation of pool boiling heat transfer enhancement of alumina–water–ethylene glycol nanofluids. Exp Therm Fluid Sci 44:805–814

Kline SJ, McClintock FA (1953) Describing uncertainties in single-sample experiments. Mech Eng 75(1):3–12

Gorenflo D (1993) Pool boiling heat transfer. In: VDI Heat Atlas, Chapter Ha. VDI, Dusseldorf, pp 1–13 (English version)

Rohsenow WM (1952) A method of correlating heat transfer data for surface boiling of liquids. Trans ASME 74:969

Walker P, Sheikholeslami R (2003) Assessment of the effect of velocity and residence time in CaSO4 precipitating flow reaction. Chem Eng Sci 58:3807–3816

Acknowledgments

Authors of this work tend to appreciate Semnan University for their facilities and also appreciate M. M. Sarafraz for his scientific supports.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nikkhah, V., Hormozi, F. Pool boiling heat transfer of water/γ-alumina micro-fluids around the horizontal cylinder. Heat Mass Transfer 52, 763–772 (2016). https://doi.org/10.1007/s00231-015-1593-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-015-1593-4