Abstract

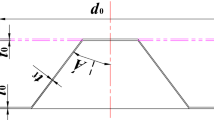

In order to shorten the preparation period, dieless shear spinning is widely used in various industrial fields with advantage of economy of materials and easy control. Controlling roller path is one of the main methods for changing thickness distribution. A new discretization method is proposed by theoretical derivation in dieless shear spinning. It will generate a virtual axis by inclining the flange of the workpiece. And, the roller path is derived for spinning machine combined with the sine law in shear spinning. The derived path should be applied after the range of forming reaches the certain height. The thickness distribution of formed workpiece is basically in agreement with the theoretical value. It also illustrates that roller nose radius and axial feed will influence the surface quality.

Similar content being viewed by others

References

Music O, Allwood JM, Kawai K (2010) A review of the mechanics of metal spinning. J Mater Process Technol 210(1):3–23

Wong CC, Dean TA, Lin J (2003) A review of spinning, shear forming and flow forming processes. Int J Mach Tool Manu 43(14):1419–1435

Quigley E, Monaghan J (2000) Metal forming: an analysis of spinning processes. J Mater Process Technol 103(1):114–119

Quigley E, Monaghan J (2002) Enhanced finite element models of metal spinning. J Mater Process Technol 121(1):43–49

Xia Q, Shima S, Kotera H, Yasuhuku D (2005) A study of the one-path deep drawing spinning of cups. J Mater Process Technol 159(3):397–400

Fazeli AR, Ghoreishi M (2011) Statistical analysis of dimensional changes in thermomechanical tube-spinning process. Int J of Adv Manuf Technol 52(5–8):597–607

Rasooli M, Moshref-Javadi M, Taherizadeh A (2015) Investigation of ultrasonic vibration effects on the microstructure and hardness of aluminum alloy 2024 tube spinning parts. Int J of Adv Manuf Technol 77(9–12):2117–2124

Molladavoudi HR, Djavanroodi F (2011) Experimental study of thickness reduction effects on mechanical properties and spinning accuracy of aluminum 7075-o, during flow forming. Int J of Adv Manuf Technol 52(52):949–957

Zhan M, Yang H, Guo J, Wang XX (2015) Review on hot spinning for difficult-to-deform lightweight metals. T Nonferr Metal Soc 25(6):1732–1743

Huang CC, Hung JC, Hung C, Lin CR (2011) Finite element analysis on neck-spinning process of tube at elevated temperature. Int J of Adv Manuf Technol 56(9):1039–1048

Mori KI, Ishiguro M, Isomura Y (2009) Hot shear spinning of cast aluminium alloy parts. J Mater Process Technol 209(7):3621–3627

Han D, Zhan M, Yang H (2013) Deformation mechanism of TA15 shells in hot shear spinning under various load conditions. Rare Met Mater Eng 42(2):243–248

Kawai K, Yang L, Kudo H (2001) A flexible shear spinning of truncated conical shells with a general-purpose mandrel. J Mater Process Technol 276(113):28–33

Avitzur B, Yang CT (1960) Analysis of power spinning of cones. J Mater Process Technol 82(3):231–244

Kalpakcioglu S (1961) On the mechanics of shear spinning. J Manuf Sci Eng 83(2):125–130

Kobayashi S, Hall IK, Thomsen EG (1961) A theory of shear spinning of cones. J Manuf Sci Eng 83(4):485–494

Kim C, Jung SY, Choi JC (2003) A lower upper-bound solution for shear spinning of cones. Int J Mech Sci 45(11):1893–1911

Arai H (2003) Robotic metal spinning-shear spinning using force feedback control. IEEE INTERNATIONAL CONFERENCE ON ROBOTICS AND AUTOMATION 3:3977–3983

Chen MD, Hsu RQ, Fuh KH (2005) An analysis of force distribution in shear spinning of cone. Int J Mech Sci 47(6):902–921

Mori K, Nonaka T (2005) Simplified three-dimensional finite element simulation of shear spinning process based on axisymmetric modeling. J Manuf Process 7(1):51–56

Kawai K, Yang LN, Kudo H (2007) A flexible shear spinning of axi-symmetrical shells with a general-purpose mandrel. J Mater Process Technol 192–193(10):13–17

Ma F, Yang H, Zhan M (2010a) Effects of material properties on power spinning process of parts with transverse inner rib. T Nonferr Metal Soc 20(8):141–149

Ma F, Yang H, Zhan M (2010b) Plastic deformation behaviors and their application in power spinning process of conical parts with transverse inner rib. J Mater Process Technol 210(1):180–189

Shima S, Kotera H, Murakami H (1997) Development of flexible spin-forming method. J Jpn Soc Technol Plastic(Plastic Process) 38(440):814–818

Wang L, Long H (2011) A study of effects of roller path profiles on tool forces and part wall thickness variation in conventional metal spinning. J Mater Process Technol 211(12):2140–2151

Sekiguchi A, Arai H (2010a) Development and evaluation of curved synchronous die-less spinning(machine elements, design and manufacturing). Trans Jpn Soc Mech Eng C 76:431–437

Xia Q, Xiao G, Long H, Cheng X, Sheng X (2014) A review of process advancement of novel metal spinning. Int J Mach Tools Manuf 85(7):100–121

Han ZR, Xu Q, Jia Z (2015) Experimental research on oblique cone die-less shear spinning. Proc Inst Mech Eng B J Eng Manuf 78(23):11772–11782

Sekiguchi A, Arai H (2010b) Control of wall thickness distribution by oblique shear spinning methods. J Mater Process Technol 51(4):984–989

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest to this work. We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Rights and permissions

About this article

Cite this article

Han, Z.R., Fan, Z.J., Xiao, Y. et al. A research on thickness distribution of oblique cone in dieless shear spinning. Int J Adv Manuf Technol 90, 2901–2912 (2017). https://doi.org/10.1007/s00170-016-9565-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9565-5