Abstract

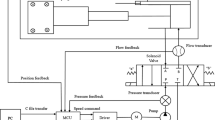

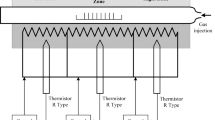

This paper shows fuzzy and neuro-fuzzy intelligent systems for automatic control of mold filling employed in casting plants. The concept of precision mold filling presupposes three key points in the process, i.e., precise pouring of the stream into the basin, maintaining constant level of molten metal in the basin, and finally, elimination of overflow of molten metal from the mold. The possibility of using fuzzy and neuro-fuzzy controls of mold-filling process was tested on a laboratory plant. Instead of molten metal, water was used, due to the approximate value of the Reynolds number of steel (1560–1600 °C) and water at room temperature. Fuzzy and neuro-fuzzy controls of casting process were tested through many experimental attempts which have confirmed the possibility of application of these methodologies in the control of gravity casting process.

Similar content being viewed by others

REFERENCES

Terashima K (1988) Recent automatic pouring and transfer systems in foundries. Mater Process Technol 39(6):1–8

Lindsay W (1983) Automatic pouring and metal distribution systems. Foundry Trade J 6:151–176

Thielk J (1987) Using electric furnaces to store and pour treated ductile iron part 2. Mod Cast 77(11):25–27

Watanabe J, Yoshida K (1992) Automatic pouring equipment for casting “mel pore system. Ind Heat 29(4):19–27

Bex T (1992) Melting & pouring. Mod Cast, pp:26–34

Miske J (1979) A look at automatic metal pouring. Foundry M & T:26–43

Sugimoto Y, et al (2002) Liquid level control of automatic pouring robot by two-degrees of freedom control, Proceedings of the 15th IFAC World Congress, Barcelona, Spain, pp 1172–1178

Yoshiyuki N, et al (2005) Control of self-transfer-type automatic pouring robot with cylindrical ladle, Proceedings of the 16th IFAC World Congress, Praha, pp 1470–1476

Noda Y, Terashima K (2007) Modeling and flow rate control of automatic pouring system. J Robotic Mechatronics 19(2):205–2011

Yano K, Terashima K (2010) Supervisory control of automatic pouring machine. Control Eng Practice 18:230–241

Zadeh AL (1965) Fuzzy sets. Inform Control 8(3):338–353

Zadeh L (1996) Fuzzy logic equals computing with words. IEEE T Fuzzy Syst 4(2):103–111

Zadeh L (1997) Toward a theory of fuzzy information granulation and its centrality in human reasoning and fuzzy logic. Fuzzy Sets Syst 90(2):111–127

Mitra S, Hayashi Y (2000) Neuro-fuzzy rule generation: survey in soft computing framework. Neural Networks, IEEE Transactions 11(3):748–768

Jang JS (1993) ANFIS: adaptive-network-based fuzzy inference system. Systems, Man and Cybernetics, IEEE Transactions 23(3):665–685

Azadegana A et al (2011) Fuzzy logic in manufacturing: a review of literature and a specialized application. Int J Prod Econ 132(2):258–270

Zuperl U et al (2005) Fuzzy control strategy for an adaptive force control in end-milling. J Mater Process Technol 164–165:1472–1478

Das A et al (2008) A rule-based fuzzy-logic approach for the measurement of manufacturing flexibility. Int J Adv Manuf Tech 38(11–12):1098–1113

Parchami A et al (2010) An effective approach for measuring the capability of manufacturing processes. Prod Plan Control 21(3):250–257

Shin CY, Vishnupad P (1996) Neuro-fuzzy control of complex manufacturing processes. Int J Prod Res 34(12):3291–3309

Petković D et al (2013) Adaptive neuro fuzzy estimation of underactuated robotic gripper contact forces. Expert Syst Appl 40(1):281–286

Nauck D (1997) Neuro-fuzzy systems: review and prospects, In Proceedings of fifth European Congress on intelligent techniques and soft computing (EUFIT’97), pp 1044–1053

Abraham A (2005) Adaptation of fuzzy inference system using neural learning, In Fuzzy Systems Engineering. Springer, Berlin Heidelberg

Shoorehdeli MA, Teshnehlab M, Sedigh AK, Khanesar MA (2009) Identification using ANFIS with intelligent hybrid stable learning algorithm approaches and stability analysis of training methods. Applied Soft Comput 9(2):2009

Jang JSR, Sun CT, Mizutani E (1997) Neuro-fuzzy and soft computing: a computational approach to learning and machine intelligence. Prentice Hall, Upper Saddle River, NJ

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dučić, N., Milićević, I., Ćojbašić, Ž. et al. Intelligent system for automatic control of the process of filling the mold. Int J Adv Manuf Technol 90, 2223–2231 (2017). https://doi.org/10.1007/s00170-016-9552-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9552-x