Abstract

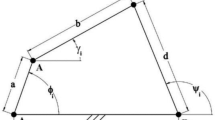

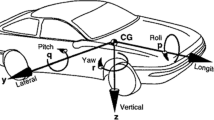

The working mechanism is an important part of a wheel loader. It is used to accomplish the shoveling, loading, lifting, and dumping tasks. Usually, the working mechanism is a Z-bar linkage and the dimensional design of the linkage directly affects the loader’s service performance, such as dumping clearance and dumping height. As there are many other performance indexes and various field requirements for the loader, comprehensive optimum, and adaptable design methodology with full-parameterized kinematic model attracts engineers’ research interests. Focusing on the multi-objective and multi-variable problems, this paper firstly establishes an accurate and simplified kinematic model of the Z-bar linkage with deduced expression of the basic parameters, and then investigates the performance indexes including mechanism transmission ratio, lifting stationary, dumping angle in any position, bucket flat setting, and extreme transmission angle, etc. With the full-parameterized kinematic model and the optimum algorithm, modified complex method, a comprehensive and adaptable design platform is built to solve the multi-objective and multi-variable problems of the Z-bar linkage. A case study with two optimization schemes as “full variables design” and “partial variable design” is conducted. The simulation results show that both schemes are better than the original one. The methodology and platform in this paper are of importance in generating user requirement oriented linkage design schemes with enough consideration and optimization of multiple performance indexes.

Similar content being viewed by others

References

Wang GB, Yang LF (1999) Optimization of wheel loader working mechanism. Mechanical Industry Press, Beijing

Wang ZW (2009) Optimization design and experimental research on the working equipment of wheel loader. Dissertation, University of Jilin

Dai WY, Liang H (2004) Dynamic simulation and comprehensive optimum design of working mechanism of loader. Journal of Jilin University of Technology (Engineering and Technology Edition) 34(4):602–605. doi:10.13229/j.cnki.jdxbgxb2004.04.017

Yu Y, Shen LG et al (2010) Optimum design of working device of wheel loader. IEEE International Conference on Mechanic Automation and Control Engineering, Hefei, pp 461–465

Gao YG, Wang GB (2005) Optimum design of the working mechanism of loader with genetic algorithms. China mechanical engineering 16(6):487–494

Gao XH, Wang YC, Erzhong A, Han JW (2007) Optimization of the working device of loader based on ADAMS. Computer Simulation 24(1):217–221

Shen WQ (2005) Virtual optimized design and finite element analysis about loaders working device. Dissertation, University of Jilin

Zhang RY, Qi JJ, Cui Y (2008) Intelligent optimum design of the working mechanism of loader. Proceedings of the 7th World Congress on Intelligent Control and Automation (WCICA), Chongqing, pp 3081–3086

Zhu YL, Feng PC, Gao Q (2007) Simulation and optimization design of Z-bar linkage working mechanism of a wheel loader. Construction Mechanization 2(4):35–36. doi:10.13311/j.cnki.conmec.2007.04.009

Shin K, Lee S, et al. (2012) Couple linkage system optimization for minimum power consumption. J Mech Sci Technol 26(2):1099–1106. doi:10.1007/s12206-011-1215-0

Yang YL, Shen G, Li MJ (2010) Optimum design of working device of wheel loader. IEEE CS’ CPS, New York

Shen JL, Wang GQ, Bi QS, Qu JN (2013) A comprehensive genetic algorithm for design optimization of Z-bar loader working mechanism. J Mech Sci Technol 27(11):3381–3394. doi:10.1007/s12206-013-0860-x

Hansen MR, Andersen TO (2003) Multi criteria design optimization of backhoe loader front mechanism. ASME International Mechanical Engineering Congress, Washington, pp 9–15

Huang HZ, Yao XS, Zhou ZR (2003) Multi-objective optimization design of the working unit of loader based on the satisfactory degree theory. Chin J Mech Eng-EN 39(5):97–103

Gu PH, Xue D, Nee AYC (2009) Adaptable design: concepts, methods, and applications. Proc Inst Mech Eng B J Eng Manuf 223(11):1367–1387

Li Y, Liu WY, Frimpong S (2015) Compound mechanism modeling of wheel loader front-end kinematics for advance engineering simulation. Int J Adv Manuf Technol 78(1):341–349. doi:10.1007/s00170-014-6640-7

Peter RN, Childs (2014) Mechanical design engineering handbook. Butterworth-Heinemann Press, Amsterdam

Cheng Q, Zhang GJ, Liu ZF, Gu PH, Cai LG (2011) A structure-based approach to evaluation product adaptability in adaptable design. J Mech Sci Technol 25(5):1081–1094. doi:10.1007/s12206-011-0224-3

Gu PH, Hashemina M, Nee AYC (2004) Adaptable design. CIRP Ann Manuf Technol 53(2):539–557. doi:10.1016/S0007-8506(07)60028-6

Zhang J, Chen YL, Xue DY, Gu PH (2014) Robust design of configurations and parameters of adaptable products. Front Mech Eng 9(1):1–14

Hong G, Hu L, Xue D, Tu YL, Xiong YL (2008) Identification of the optimal product configuration and parameters based on individual customer requirements on performance and costs in one-of-a-kind production. Int J Prod Res 46(12):3297–3326. doi:10.1080/00207540601099274

Lee BH, Kim BH (1995) Optimization of part wall thicknesses to reduce warpage of injection-molded parts based on the modified complex method. Polym-Plast Technol 34(5):793–811

Sahoo NK, Apparao KVSR (1994) Modified complex method for constrained design and optimization of optical multilayer thin-film devices. Appl Phys A-Mater 59(3):317–326. doi:10.1007/bf00348237

Xue D, Hua G, Mehrad V, Gu P (2012) Optimal adaptable design for creating the changeable product based on changeable requirements considering the whole product life-cycle. J Manuf Syst 31(1):59–68. doi:10.1016/j.jmsy.2011.04.003

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Z., He, B. Comprehensive optimum and adaptable design methodology for the working mechanism of a wheel loader. Int J Adv Manuf Technol 94, 3085–3095 (2018). https://doi.org/10.1007/s00170-016-9312-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9312-y