Abstract

Working accuracy and service life of large structural parts such as lathe beds, columns, etc. of a heavy-duty machine tool with large self-weight is directly influenced by the foundation-soil system. Therefore, simulation of the interaction of the heavy-duty machine tool and its foundation-soil system is a key technological requirement from a manufacturing perspective. However, owing to the size of the structural parts of most heavy-duty machine tools, and the complex and oversized structure of their foundation-soil system, typical simulation environments fail to meet the computational requirements. With an aim to carry out simulations and meet the computational demand for the interaction of heavy-duty machine tools and their foundation-soil system; a constitutive model with a transversely isotropic composite material (the reinforced concrete foundation) was developed to reduce computation load. Then, based on fractal theory, equations for calculating stiffness of the joint surface and damping matrix were deduced to overcome common technical difficulty facing the heavy-duty machine tool industry. Meanwhile, establishing a finite element model (FEM) framework in a cloud-computing environment, rapid solution of the FE model for heavy-duty machine tool foundation-soil system interactions was realized. Finally, a comparison of experimental results can be used to validate accuracy of the analysis. Furthermore, cloud-computing simulation of a heavy-duty machine tool foundation-soil system was used to evaluate efficacy of different types of isolation trenches. The results provide a basis for the construction of the foundations of a heavy-duty machine tool and the selection of an optimisation scheme.

Similar content being viewed by others

References

Laili Y, Tao F, Zhang L, Sarker BR (2012) A study of optimal allocation of computing resources in cloud manufacturing systems. Int J Adv Manuf Technol 63(5-8):671–690. doi:10.1007/s00170-012-3939-0

David C, Chou Cloud computing (2015) A value creation model computer. Standards Interfaces 38:72–77. doi:10.1016/j.csi.2014.10.001

Leonard B, Chen X, Fatos X (2015) Advances on cloud services and cloud computing. Concurrency Comput 27(8):1985–1987. doi:10.1002/cpe.3414

Andreadis G, Drossos A (2013) A cloud based framework for automated cad design. Int J Mod Manuf Technol 5(2):15–20

Andreadis G, Fourtounis G, Bouzakis KD (2015) Collaborative design in the era of cloud computing. Adv Eng Softw 81(C):66–72. doi:10.1016/j.advengsoft.2014.11.002

Valilai OF, Houshmand M (2013) A collaborative and integrated platform to support distributed manufacturing system using a service-oriented approach based on cloud computing paradigm. Robot Comput Integr Manuf 29(1):110–127. doi:10.1016/j.rcim.2012.07.009

Tingxin S, Huimin L, Chunmei W, Chenglei Z (2014) Common engines of cloud manufacturing service platform for SMEs. Int J Adv Manuf Technol 73(1-4):557–569. doi:10.1007/s00170-014-5863-y

Chandrasekaran M, Muralidhar M, Dixit US (2013) Online optimization of multipass machining based on cloud computing. Int J Adv Manuf Technol 65(1-4):239–250. doi:10.1007/s00170-012-4163-7

Tao F, Zhao D, Hu Y, Zhou Z (2008) Resource service composition and its optimal-selection based on particle swarm optimization in manufacturing grid system. IEEE Trans Ind Inf 4(4):315–327. doi:10.1109/TII.2008.2009533

Tao F, Zhang L, Venkatesh VC, Luo Y, Cheng Y (2011) Cloud manufacturing: a computing and service-oriented manufacturing model. Proc Inst Mech Eng B J Eng Manuf 225(10):1969–1976. doi:10.1177/0954405411405575

Li JR, Tao F, Cheng Y, Zhao L (2015) Big data in product data management. Int J Adv Manuf Technol 81(1):667–684. doi:10.1007/s00170-015-7151-x

Tao F, Cheng Y, Zhang L, Nee AYC (2015) Advanced manufacturing systems: socialization characteristics and trends. J Int Manuf. doi:10.1007/s10845-015-1042-8

Tao F, Laili YJ, Xu L, Zhang L, FC-PACO-RM (2013) A parallel method for service composition optimal-selection in cloud manufacturing system. IEEE Trans Ind Inf 9(4):2023–2033. doi:10.1109/TII.2012.2232936

Tao F, Zuo Y, Xu L, Zhang L (2014) IoT-based intelligent perception and access of manufacturing resource toward cloud manufacturing. IEEE Trans Ind Inf 10(2):1547–1557. doi:10.1109/TII.2014.2306397

Tao F, Cheng Y, Xu L, Zhang L, Li BH (2014) CCIoT-CMfg: cloud computing and internet of things based cloud manufacturing service system. IEEE Trans Ind Inf 10(2):1435–1442. doi:10.1109/TII.2014.2306383

Tao F, Zhang L, Liu YK, Cheng Y, Wang LH, Xun X (2015) Manufacturing service management in cloud manufacturing: overview and future research directions. J Manuf Sci Eng Trans ASME. doi:10.1115/1.4030510

Park JH, Jeong HY (2014) Cloud computing-based jam management for a manufacturing system in a Green IT environment. J Supercomput 69(3):1054–1067. doi:10.1007/s11227-013-1007-7

Rubén C, Younas M (2015) Emerging trends and technologies in big data processing. Concurrency Comput:Pract Exp 27(8):2078–2091. doi:10.1109/TII.2014.2306383

Ren Y, Beards CF (1998) Identification of ‘Effective’ linear joints using coupling and joint identification techniques. ASME J Vib Acoust 120(2):331–338

Ibrahim RA, Pettit CL (2005) Uncertainties and dynamic problems of bolted joints and other fasteners. J Sound Vib 279(35):857–936. doi:10.1016/j.jsv.2003.11.064

Burdekin M, Cowley AB (1979) Analysis of the local deformation in machine joints. Mech Eng Sci 34(3):15–17

Zhang GP, Huang YM, He SW (2003) Predicting dynamic behaviours of a whole machine tool structure based on computer-aided engineering. Int J Mach Tools Manuf 43(07):699–706. doi:10.1016/S0890-6955(03)00026-9

Yan W, Komvopoulos K (1998) Contact analysis of elastic–plastic fractal surfaces. J Appl Phys 84(7):3617–3624. doi:10.1063/1.368536

Kogut L, Etsion I (2002) Elastic-plastic contact analysis of a sphere and a rigid flat. J Appl Mech 69(5):657–662. doi:10.4028/www.scientific.net/AMR.644.151

Goodman RE, Tayler RL, Brekke TL (1968) A model for the mechanics of jointed rock. J Soil Mech Found Div Proc ASCE 94(3):637–660

Wang M, Zhou X, Hu Y (2005) Studies on contact model of soil-pile dynamic interaction. Chinese J Geotech Eng 27(6):616–620

Deeks AJ, Randolph MF (1994) Axisymmetric time-domain transmitting boundaries. J Eng Mech 120(1):25–42

Nguyen-Thoi T, Van Phung P, Rabczuk T, Nguyen Xuan H, Le Van C (2013) Free and forced vibration analysis using the n-sided polygonal cell-based smoothed finite element method (nCS-FEM). Int J Comput Methods 10(1):1–19. doi:10.1142/S0219876213400082

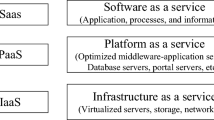

Vânia G, Pieter B (2011) Adding value to the network: mobile operators’ experiments with software-as-a-service and platform-as-a-service models. Telematics Inform 28(1):12–21. doi:10.1016/j.tele.2010.05.005

Kim IH, Tsou MH (2013) Enabling digital earth simulation models using cloud computing or grid computing two approaches supporting high-performance GIS simulation frameworks. Int J Digital Earth 6(4):383–403. doi:10.1080/17538947.2013.783125

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cai, L., Tian, Y., Liu, Z. et al. Application of cloud computing to simulation of a heavy-duty machine tool. Int J Adv Manuf Technol 84, 291–303 (2016). https://doi.org/10.1007/s00170-015-7916-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7916-2