Abstract

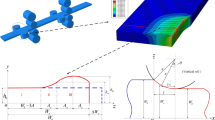

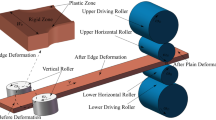

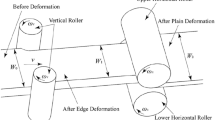

Vertical rolling has been widely used in the roughing stand of hot strip rolling to improve the precision of slab width which influences the finished product quality significantly in actual production. Double parabolic dog-bone function model and corresponding velocity and strain rate fields are firstly proposed based on the incompressibility condition and stream function. They are successfully applied to three-dimensional vertical rolling. Using the first variation principle of rigid-plastic material, an analytical solution of slab total power functional in vertical rolling is obtained. Then, the shape parameters and the rolling force are received by minimizing the power functional. The error of shape and power parameters is within 4 % compared with finite element method (FEM) simulation’s result and less than 9.5 % compared with other models’ result.

Similar content being viewed by others

References

Ginzburg VB (1989) Steel-rolling technology: theory and practice. Marcel Dekker, New York

Shibahara T, Misaka Y, Kono T, Koriki M, Takemoto H (1981) Edger set-up model at roughing train in a hot strip mill. Tetsu To Hagane 67(15):2509–2515

Okado M, Ariizumi T, Noma Y, Yabuuchi K, Yamazaki Y (1981) Width behaviour of the head and tail of slabs in edge rolling in hot strip mills. Tetsu To Hagane 67(15):2516–2525

Tazoe N, Honjyo H, Takeuchi M, Ono T (1984) New forms of hot strip mill width rolling installations. AISE Spring Conference, Dearborn, pp 85–88

Ginzburg VB, Kaplan N, Bakhtar F, Tabone CJ (1991) Width control in hot strip mills. Iron Steel Eng 68(6):25–39

Xiong SW, Rodrigues JMC, Martins PAF (2003) Three-dimensional modelling of the vertical-horizontal rolling process. Finite Elem Anal Des 39(11):1023–1037. doi:10.1016/s0168-874x(02)00154-3

Yun D, Lee D, Kim J, Hwang S (2012) A new model for the prediction of the dog-bone shape in steel mills. ISIJ Int 52(6):1109–1117

Tabatabaei SA, Abrinia K, Givi MKB (2014) Application of equi-potential lines method for accurate definition of the deforming zone in the upper-bound analysis of forward extrusion problems. Int J Adv Manuf Tech 72(5–8):1039–1050. doi:10.1007/s00170-014-5647-4

Wang GD, Zhao DW (2004) Modern material forming mechanics. Northeastern University Press, Shenyang

Yu MH (1983) Twin shear stress yield criterion. Int J Mech Sci 25(1):71–74

Zhao DW, Xie YJ, Liu XH, Wang GD (2006) Three-dimensional analysis of rolling by twin shear stress yield criterion. J Iron Steel Res Int 13(6):21–26. doi:10.1016/s1006-706x(06)60104-0

Yan ZD, Bu XM (1993) The method of characteristics for solving the plane stress problem of ideal rigid-plastic body on the basis of Twin shear stress yield criterion. Advances in Engineering Plasticity and its Applications:295–302

Abrinia K, Mirnia MJ (2009) A new generalized upper-bound solution for the ECAE process. Int J Adv Manuf Tech 46(1–4):411–421. doi:10.1007/s00170-009-2103-y

Deng W, Zhao DW, Qin XM, Gao XH, Du LX, Liu XH (2010) Linear integral analysis of bar rough rolling by strain rate vector. J Iron Steel Res Int 17(3):28–33

Zhao DW, Fang Q, Li CM, Liu XH, Wang GD (2010) Derivation of plastic specific work rate for equal area yield criterion and its application to rolling. J Iron Steel Res Int 17(4):34–38

Lan LY, Li CM, Zhao DW, Qiu CL (2012) Derivation of equal area criterion and its application to crack Tip plastic zone analysis. Appl Mech Mater 110:2918–2925

Hua L, Deng JD, Qian DS, Ma Q (2014) Using upper bound solution to analyze force parameters of three-roll cross rolling of rings with small hole and deep groove. Int J Adv Manuf Tech 76(1–4):353–366. doi:10.1007/s00170-014-6107-x

Li XP, Cai MB, Rahman M, Liang S (2009) Study of the upper bound of tool edge radius in nanoscale ductile mode cutting of silicon wafer. Int J Adv Manuf Tech 48(9–12):993–999. doi:10.1007/s00170-009-2347-6

Zhang SH, Zhao DW, Gao CR (2012) The calculation of roll torque and roll separating force for broadside rolling by stream function method. Int J Mech Sci 57(1):74–78. doi:10.1016/j.ijmecsci.2012.02.006

Zhao ZY (1980) Metal plastic deformation and rolling theory. Metallurgical Industry Press, Beijing

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, YM., Zhang, DH., Zhao, DW. et al. Analysis of vertical rolling using double parabolic model and stream function velocity field. Int J Adv Manuf Technol 82, 1153–1161 (2016). https://doi.org/10.1007/s00170-015-7393-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7393-7