Abstract

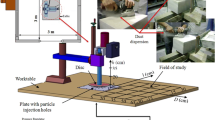

Environmental, occupational health and safety regulations are pushing manufacturers towards reducing of manufacturing hazards including aerosol and fine particles. Granite shaping, cutting, and polishing are some of these processes producing large amount of dust containing silica that must be controlled. At the same time, the machining conditions must remain competitive and cost-effective and lead to quality parts. The goal of this work is to address these issues by determining the factors governing the dust emission during granite polishing in order to reduce the risk of exposition while producing quality parts. To do so, experimental polishing tests were carried on a vertical CNC machining center using an adaptable tool holder which controlled the contact pressure during the tests. Diamond polishing tools with different grit sizes were used. The workpiece tested were two granites, one with high silica content (white granite) and another with low silica content (black granite). The output responses studied include the surface finish, the forces, and the fine particle emission and dispersion. The experimental results led to establishing relationships between the surface finish, dust emission, and cutting forces on one hand and the abrasive sizes and polishing conditions on the other hand. It was found that the polishing tool grit size governs not only the granite surface finish but also the fine particle emission and the chip removal mechanism.

Similar content being viewed by others

References

Simcox NJ, Lofgren D, Leons J, Camp J (1999) Silica exposure during granite countertop fabrication. Appl Occup Environ Hyg 14(9):577–582

Phillips ML, Johnson DL, Johnson AC (2013) Determinants of respirable silica exposure in stone countertop fabrication: a preliminary study. J Occup Environ Hyg 10(7):368–373

Verma DK, Vacek PM, des Tombe K, Finkelstein M, Branch B, Gibbs GW et al (2011) Silica exposure assessment in a mortality study of vermont granite workers. J Occup Environ Hyg 8(2):71–79

Steenland K, Ward E (2014) Silica: a lung carcinogen. CA Cancer J Clin 64(1):63–69

Sánchez DN, Rodríguez-Rey A, Suárez del Río LM, Díez Sarriá I, Calleja L, Ruiz de Argandoña VG (2005) The influence of rock microhardness on the sawability of Pink Porrino granite (Spain). Int J Rock Mech Min Sci 42(1):161–166

Xie J, Tamaki J (2007) Parameterization of micro-hardness distribution in granite related to abrasive machining performance. Mater Process Technol 186(1–3):253–258

Xu XP, Huang H, Li Y (2003) Material removal mechanisms in diamond grinding of granite, part 1: the morphological changes of granite from sawing to grinding. Key Eng Mater 250:215–221

Min Z, Xiying L (2010) Experimental research on cutting force with diamond mill cutting granite. in 2010 Int. Conf. on Mechanic Automation and Control Engineering (MACE). IEEE, Piscataway

Yavuz H, Ozkahraman T, Demirdag S (2011) Polishing experiments on surface quality of building stone tiles. Constr Amp Build Mater 25(4):1707–1711

Yilmaz NG, Goktan RM, Gasan H, Celik O N (2013) Particle size distribution and shape characterization of the chips produced during granite machining in relation to process forces and specific energy. Part Sci Technol 31(3):277–286

Huang H, Xu XP (2004) Interfacial interactions between diamond disk and granite during vertical spindle grinding. Wear 256(6):623–629

Huang H, Li Y, Shen JY, Zhu HM, Xu XP (2002) Micro-structure detection of a glossy granite surface machined by the grinding process. in 10th Int. Manufacturing Conf., China (IMCC 2002). Elsevier, Fujian

Li Y, Huang H, Xu XP (2006) Gloss formation and its relationship with roughness in granite grinding. Key Eng Mater 304–305:413–416

Rocha-Parise M, Santos LMB, Damoiseaux J GM C, Bagatin E, Lido AV, Torello CO et al (2013) Lymphocyte activation in silica-exposed workers. Int J Hyg Environ Health 217(4–5):586–591

Liu Y, Steenland K, Rong Y, Hnizdo E, Huang X, Zhang H et al (2013) Exposure-response analysis and risk assessment for lung cancer in relationship to silica exposure: a 44-year cohort study of 34,018 workers. Am J Epidemiol 178(9):1424–1433

Ahmad I, Khan MI, Patil G (2011) Nanotoxicity of occupational dust generated in granite stone saw mill. in 2011 International Conference on Nanoscience, Technology and Societal Implications. IEEE, Piscataway

Kouam J, Songmene V, Balhoul A (2013) Experimental investigation on PM2.5 particle emission during polishing of granite. Health 5(10 A2):29–35. doi:10.4236/health.2013.510A2004

Preston FW (1927) The theory and design of plate glass polishing. Soc Glass Technol J 11(42):214–256

SAE- Society of Automotive Engineers (1988) Manual on design and manufacture of coned disk springs (Belleville Springs) and spring washers, 1st edn. SAE, Warrendale, 35 p

Belkhir N, Bouzid D, Herold V (2009) Determination of the friction coefficient during glass polishing. Tribol Lett 33(1):55–61

Yaonan C, Li L, Haiting W, Mingyang W, Yizhi L (2014) Investigations on the dust distribution characteristics of dry milling using inserts with various groove profiles. Int J Adv Manuf Technol 74(1–4):551–562

Pozzi R, De Barardis B, Paoletti L, Guastadisegni C (2003) Inflammatory mediators induced by coarse (PM2.5-10) and fine (PM2.5) urban air particles in RAW 264.7 cells. Toxicology 183:143–254

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saidi, M.N., Songmene, V., Kouam, J. et al. Experimental investigation on fine particle emission during granite polishing process. Int J Adv Manuf Technol 81, 2109–2121 (2015). https://doi.org/10.1007/s00170-015-7303-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7303-z