Abstract

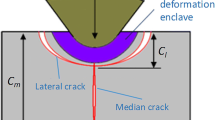

The usage of carbon-fiber-reinforced polymer (CFRP) composite keeps increasing in modern industries. However, the machining mechanism of CFRP, especially the microscopic machining mechanism, is not well understood yet. This paper aims to establish a force prediction model for orthogonal cutting of unidirectional CFRP (UD-CFRP) in microscale. The deflection of the representative volume element (RVE), composed of a single fiber and the surrounding matrix, is analyzed considering the effect of the surrounding materials based on the minimum potential energy principle (MPEP). The critical force in the cutting edge that causes fracture of the RVE is obtained according to the bending deflection expression of the RVE. In addition, by taking slipping, peeling, and bounding mechanism in three different deformation areas into consideration, a force prediction model of UD-CFRP orthogonal cutting is established for fiber orientation ranging from 0° to γ α + 90°. Several experiments have been conducted, and the results comparison shows that the model, though approximately, has gotten acceptable agreement with the experimental results, which proves the effectiveness of the analysis method.

Similar content being viewed by others

References

Iliescu D, Gehin D, Iordanoff I, Girot F, Gutiérrez ME (2010) A discrete element method for the simulation of CFRP cutting. Compos Sci Technol 70(1):73–80

Chibane H, Morandeau A, Serra R, Bouchou A, Leroy R (2013) Optimal milling conditions for carbon/epoxy composite material using damage and vibration analysis. Int J Adv Manuf Technol 68(5–8):1111–1121

Silva D, Teixeira JP, Machado CM (2014) Methodology analysis for evaluation of drilling-induced damage in composites. Int J Adv Manuf Technol 71(9–12):1919–1928

Jayabal S, Natarajan U (2010) Optimization of thrust force, torque, and tool wear in drilling of coir fiber-reinforced composites using Nelder–Mead and genetic algorithm methods. Int J Adv Manuf Technol 51(1–4):371–381

Che D, Saxena I, Han P, Guo P, Ehmann KF (2014) Machining of carbon fiber reinforced plastics/polymers: a literature review. J Manuf Sci Eng 136(3):034001

Karpat Y, Deger B, Bahtiyar O (2014) Experimental evaluation of polycrystalline diamond tool geometries while drilling carbon fiber-reinforced plastics. Int J Adv Manuf Technol 71(5–8):1295–1307

Montoya M, Calamaz M, Gehin D, Girot F (2013) Evaluation of the performance of coated and uncoated carbide tools in drilling thick CFRP/aluminium alloy stacks. Int J Adv Manuf Technol 68(9–12):2111–2120

Ben Soussia A, Mkaddem A, El Mansori M (2014) Rigorous treatment of dry cutting of FRP-Interface consumption concept: a review. Int J Mech Sci 83:1–29

Rahamathullah I, Shunmugam M (2014) Mechanistic approach for prediction of forces in micro-drilling of plain and glass-reinforced epoxy sheets. Int J Adv Manuf Technol 75(5–8):1177–1187

Zhou L, Hou N, Huang S, Xu L (2014) An experimental study on formation mechanisms of edge defects in orthogonal cutting of SiCp/Al composites. Int J Adv Manuf Technol 1–8

Koplev A, Lystrup A, Vorm T (1983) The cutting process, chips, and cutting forces in machining CFRP. Composites 14(4):371–376

Wang DH, Ramulu M, Arola D (1995) Orthogonal cutting mechanisms of graphite/epoxy composite. Part I: unidirectional laminate. Int J Mach Tools Manuf 35(12):1623–1638

Albert G, Laheurte R, K’Nevez J-Y, Darnis P, Cahuc O (2011) Experimental milling moment model in orthogonal cutting condition: to an accurate energy balance. Int J Adv Manuf Technol 55(9–12):843–854

Işık B (2008) Experimental investigations of surface roughness in orthogonal turning of unidirectional glass-fiber reinforced plastic composites. Int J Adv Manuf Technol 37(1–2):42–48

Işık B, Ekici E (2010) Experimental investigations of damage analysis in drilling of woven glass fiber-reinforced plastic composites. Int J Adv Manuf Technol 49(9–12):861–869

Arola D, Ramulu M (1997) Orthogonal cutting of fiber-reinforced composites: a finite element analysis. Int J Mech Sci 39(5):597–613

Rao GVG, Mahajan P, Bhatnagar N (2007) Micro-mechanical modeling of machining of FRP composites-Cutting force analysis. Compos Sci Technol 67(3–4):579–593

Rao GVG, Mahajan P, Bhatnagar N (2007) Machining of UD-GFRP composites chip formation mechanism. Compos Sci Technol 67(11–12):2271–2281

Chakladar ND, Pal SK, Mandal P (2012) Drilling of woven glass fiber-reinforced plastic—an experimental and finite element study. Int J Adv Manuf Technol 58(1–4):267–278

Calzada KA, Kapoor SG, DeVor RE, Samuel J, Srivastava AK (2012) Modeling and interpretation of fiber orientation-based failure mechanisms in machining of carbon fiber-reinforced polymer composites. J Manuf Process 14(2):141–149

Bhatnagar N, Ramakrishnan N, Naik NK, Komanduri R (1995) On the machining of fiber reinforced plastic (FRP) composite laminates. Int J Mach Tools Manuf 35(5):701–716

Zhang LC, Zhang HJ, Wang XM (2001) A force prediction model for cutting unidirectional fibre-reinforced plastics. Mach Sci Technol 5(3):293–305

Wang XM, Zhang LC (2003) An experimental investigation into the orthogonal cutting of unidirectional fibre reinforced plastics. Int J Mach Tools Manuf 43(10):1015–1022

Zhang LC (2009) Cutting composites: A discussion on mechanics modelling. J Mater Process Technol 209(9):4548–4552

Singh I, Bhatnagar N (2006) Drilling of uni-directional glass fiber reinforced plastic (UD-GFRP) composite laminates. Int J Adv Manuf Technol 27(9–10):870–876

Rahmé P, Landon Y, Lachaud F, Piquet R, Lagarrigue P (2011) Analytical models of composite material drilling. Int J Adv Manuf Technol 52(5–8):609–617

Sahraie Jahromi A, Bahr B (2010) An analytical method for predicting cutting forces in orthogonal machining of unidirectional composites. Compos Sci Technol 70(16):2290–2297

Reifsnider KL (2002) Case SW. Damage tolerance and durability of material systems. John Wiley, New York

Beer F, Johnston E, DeWolf J (2002) Mechanics of Materials, 2002. McGraw-Hill, New York

Winkler E (1867) Theory of elasticity and strength. Prague, Dominicus

Boresi AP, Schmidt RJ, Sidebottom OM (1993) Advanced mechanics of materials. Wiley, New York

Everstine GC, Rogers TG (1971) A theory of machining of fiber-reinforced materials. J Compos Mater 5(1):94–106

Guo DM, Wen Q, Gao H, Bao YJ (2011) Prediction of the cutting forces generated in the drilling of carbon-fibre-reinforced plastic composites using a twist drill. P I Mech Eng B-J Eng 226(1):28–42

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qi, Z., Zhang, K., Cheng, H. et al. Microscopic mechanism based force prediction in orthogonal cutting of unidirectional CFRP. Int J Adv Manuf Technol 79, 1209–1219 (2015). https://doi.org/10.1007/s00170-015-6895-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-6895-7