Abstract

Sound AA2024-T3–Cu10100 dissimilar joints were obtained by friction stir welding offsetting the tool probe towards the aluminum sheet and employing selected processing parameters. Joint microstructure was analyzed by means of conventional optic microscopy as well as scanning electron microscopy. The weld bead exhibited welding zones and some features typically encountered in similar FSW. The nugget zone consisted of a mixture of recrystallized aluminum matrix and deformed and twinned copper particles. Onion rings and particle-rich zones, made of Cu particles dispersed in the Al matrix, were also observed. EDS analysis revealed that several Al–Cu intermetallic compounds, such as Al2Cu, AlCu, and Al3Cu4, chemically different w.r.t. compounds precipitated during the T3 aging treatment (Al3Cu), were formed during the process. Microstructure variation significantly affects the microhardness distribution in the cross-section of the joint.

Similar content being viewed by others

References

Ouyang J, Yarrapareddy E, Kovacevic R (2006) Microstructural evolution in the friction stir welded 6061 aluminum alloy (T6-temper condition) to copper. J Mater Process Technol 172:110–122

Murr LE, Flores RD, Flores OV, McClure JC, Liu G, Brown D (1998) Friction stir welding: microstructural characterization. Mater Res Innovation 1(4):211–223

Murr LE, Ying L, Trillo EA, Flores RD, McClure JC (1998) Microstructure in friction stir welded metals. J Mater Process Manuf Sci 7:145–161

Dawes CJ (1977) Micro-friction welding aluminum studs to mild steel plates. Met Constr 9(5):196–197

Sun Z, Karppi R (1996) The application of electron beam welding for the joining of dissimilar metals: an overview. J Mater Process Technol 59:257–267

Aravind M, Yu P, Yau MY, Dickon HLN (2004) Formation of Al2Cu and AlCu intermetallics in Al(Cu) alloy matrix composites by reaction sintering. Mater Sci Eng A 380:384–393

Liu P, Shi Q, Wang W, Wang X, Zhang Z (2008) Microstructure and XRD analysis of FSW joints for copper T2/aluminium 5A06 dissimilar materials. Mater Lett 62:4106–4108

Galvão I, Oliveira JC, Loureiro A, Rodrigues DM (2012) Formation and distribution of brittle structures in friction stir welding of aluminium and copper: Influence of shoulder geometry. Intermetallics 22:122–128

Abbasi M, Karimi Taheri A, Salehi MT (2001) Growth rate of intermetallic compounds in Al/Cu bimetal produced by cold roll welding process. J Alloy Compd 319:233–241

Squillace A, De Fenzo A, Giorleo G, Bellucci F (2004) A comparison between FSW and TIG welding techniques: modifications of microstructure and pitting corrosion resistance in AA 2024-T3 butt joints. J Mater Process Technol 152(1):97–105

Mofid MA, Abdollah-Zadeh A, Gür CH (2014) Investigating the formation of intermetallic compounds during friction stir welding of magnesium alloy to aluminum alloy in air and under liquid nitrogen. Int J Adv Manuf Technol 71(5–8):1493–1499

Yilbas BS, Sahin AZ, Kahraman N, Al-Garni AZ (1995) Friction welding of steel–Al and Al–Cu materials. J Mater Process Technol 49:431–443

Midling OT, Grong Ø (1994) A process model for friction welding of Al–Mg–Si alloys and Al–SiC metal matrix composites-I. HAZ temperature and strain rate distribution. Acta Metall Mater 42(5):1595–1609

Lee WB, Jung SB (2003) Void free friction stir weld zone of the dissimilar 6061 aluminum and copper joint by shifting the tool insertion location. Mater Res Innov 8(2):93–96

Pratik Agarwal S, Prashanna Nageswaran, Arivazhagan N, Devendranath Ramkumar K (2012) Development of friction stir welded butt joints of AA 6063 aluminium alloy and pure copper. In Proceedings of the International Conference on Advanced Research in Mechanical Engineering (ICARME-2012) 13 May 2012, Trivendum, India

Saeid T, Abdollah-zadeh A, Sazgari B (2010) Weldability and mechanical properties of dissimilar aluminum–copper lap joints made by friction stir welding. J Alloy Compd 490:652–655

Watanabe T, Takayama H, Yanagisawa A (2006) Joining of aluminum alloy to steel by friction stir welding. J Mater Process Technol 178:342–349

Tanaka T, Morishige T, Hirata T (2009) Comprehensive analysis of joint strength for dissimilar friction stir welds of mild steel to aluminum alloys. Scripta Mater 61:756–759

DebRoy T, Bhadeshia HKDH (2010) Friction stir welding of dissimilar alloys—a perspective. Sci Technol Weld Joining 15:266–270

Choi DH, Lee CY, Ahn BW, Yeon YM, Park SHC, Sato YS, Kokawa H, Jung SB (2010) Effect of fixed location variation in friction stir welding of steels with different carbon contents. Sci Technol Weld Joining 15:299–304

Hussain G, Gao L, Hayat N, Dar NU (2010) The formability of annealed and pre-aged AA-2024 sheets in single-point incremental forming. Int J Adv Manuf Technol 46(5–8):543–549

ASM Handbook, Volume 04 - Heat Treating

ASM Specialty Handbook: Aluminum and Aluminum Alloys

ASM Specialty Handbook—Copper and Copper Alloys

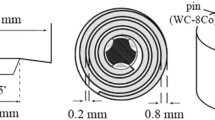

Carlone P, Palazzo GS (2013) Influence of process parameters on microstructure and mechanical properties in AA2024-T3 friction stir welding. Metallogr Microstruct Anal 2(4):213–222

Carlone P, Palazzo GS (2014) The influence of pre-heating on the weldability of pure copper by FSW. Open Mech Eng J 8:177–184

Nandan R, DebRoy T, Bhadeshia HKDH (2008) Recent advances in friction-stir welding—process, weldment structure and properties. Prog Mater Sci 3:980–1023

Reynolds AP (2008) Flow visualization and simulation in FSW. Scripta Mater 58:338–342

Xue P, Ni DR, Wang D, Xiao BL, Ma ZY (2011) Effect of friction stir welding parameters on the microstructure and mechanical properties of the dissimilar Al–Cu joints. Mater Sci Eng A 528:4683–4689

Tolephih MH, Mahmood HM, Hashem AH, Abdullah ET (2013) Effect of tool offset and tilt angle on weld strength of butt joint friction stir welded specimens of AA2024 aluminum alloy welded to commercial pure cupper. Chem Mater Res 3(4):49–58

Massalski TB (1980) The Al–Cu (aluminum-copper) system. Bull Alloy Phase Diagr 1(1):27–33

Chen CY, Chen HL, Hwang WS (2006) Influence of interfacial structure development on the fracture mechanism and bond strength of aluminum/copper Bimetal Plate. Mater Trans JIM 47:1232–1239

Jiang HG, Dai JY, Tong HY, Ding BZ, Song QH, Hu ZQ (1993) Interfacial reactions on annealing Cu/Al multilayer thin films. J Appl Phys 74:6165–6169

Peng XK, Wuhrer R, Heness G, Yeung WY (1999) On the interface development and fracture behaviour of roll bonded copper/aluminium metal laminates. J Mater Sci 34:2029–2038

Won-Bae L, Yun-Mo Y, Seung-Boo J (2003) The joint properties of dissimilar formed Al alloys by friction stir welding according to the fixed location of materials. Scripta Mater 49:423–428

Xue P, Xiao BL, Ni DR, Ma ZY (2010) Enhanced mechanical properties of friction stir welded dissimilar Al–Cu joint by intermetallic compounds. Mater Sci Eng A 527:5723–5727

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Carlone, P., Astarita, A., Palazzo, G.S. et al. Microstructural aspects in Al–Cu dissimilar joining by FSW. Int J Adv Manuf Technol 79, 1109–1116 (2015). https://doi.org/10.1007/s00170-015-6874-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-6874-z