Abstract

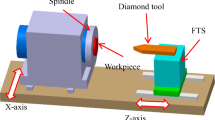

Slow tool servo (STS) turning is a superior process for machining precision and complicated surfaces that has already gained a wide application especially in optics industry. However, it is lack of systematically study of tool path generation for STS turning of complex surfaces, especially of interpolation among discrete cutting location points. This paper presents a comprehensive tool path generation strategy for STS turning of complex surfaces, including cutting location point optimized planning, trajectory interpolation, and machining simulation. First, cutting contact point discretization and tool geometry compensation were analyzed during cutting location point planning procedure. Second, Hermite segment interpolation used by trajectory interpolation was analyzed, and three position-velocity-time (PVT) entrance parameters algorithms were put forward, i.e., the constant speed method, area method, and the three points method. Third, the machining simulation was carried out to evaluate the performance of the generated tool path. The analysis of Z-axis motion characteristics indicated that both the area method (c = 2/3) and three points method can meet the requirements of smooth velocity of Z-axis when the Z-axis reciprocating frequency is similar to the C-axis rotating frequency. From the viewpoint of acceleration, the three points method is much better than the area method when the Z-axis reciprocating frequency is significantly greater than the C-axis rotary frequency. Finally, a progressive addition lens surface was fabricated to prove the feasibility of the proposed tool path generation method.

Similar content being viewed by others

References

Fang FZ, Zhang XD, Hu XT (2008) Cylindrical coordinate machining of optical freeform surfaces. Opt Express 16(10):7323–7329

Tohme Y, Murray R, Allaire P (2005) Principles and applications of the slow slide servo. <http://www.nanotechsys.com/technology/technical-papers>

Kim HS, Lee KI, Lee KM, Bang YB (2009) Fabrication of freeform surfaces using a long-stroke fast tool servo and corrective figuring with on-machine measurement. Int J Mach Tools Manuf 49(12–13):991–997

Sosnicki O, Pages A, Pacheco C, Maillard T (2010) Servo piezo tool SPT400MML for the fast and precise machining of free forms. Int J Adv Manuf Technol 47(9–12):903–910

Liu Q, Zhou X, Xu P, Zou Q, Lin C (2012) A flexure-based long-stroke fast tool servo for diamond turning. Int J Adv Manuf Technol 59(9–12):859–867

Yu DP, Hong GS, Wong YS (2012) Profile error compensation in fast tool servo diamond turning of micro-structured surfaces. Int J Mach Tools Manuf 52(1):13–23

Bang YB, Lee KM, Oh S (2005) 5-axis micro milling machine for machining micro parts. Int J Adv Manuf Tech 25:888–894

Yan JW, Zhang ZY, Kuriyagawa T, Gonda H (2010) Fabricating micro-structured surface by using single-crystalline diamond endmill. Int J Adv Manuf Tech 51(9–12):957–964

McCall B, Tkaczyk TS (2010) Fabrication of plastic microlens array for array microscopy by three-dimensional diamond micromilling. Opt Eng 49(10):103401

Wu YL, Pen WQ, Liu Y (2012) A novel fabrication method for micro optical waveguide mold based on fly-cutting technology. Int J Light Electron Opt 124(9):867–869

Kong LB, Cheung CF (2011) Prediction of surface generation in ultra-precision raster milling of optical freeform surfaces using an integrated kinematics error model. Adv Eng Softw 45(1):124–136

Yin ZQ, Dai YF, Li SY, Guan CL, Tie GP (2011) Fabrication of off-axis aspheric surfaces using a slow tool servo. Int J Mach Tools Manuf 51(5):404–410

Chen CC, Cheng YC, Hsu WY, Chou Y, Wang PJ, Tsai DP (2011) Slow tool servo diamond turning of optical freeform surface for astigmatic contact lens. Proc. SPIE 8126, Optical Manufacturing and Testing IX, doi:10.1117/12.892447

Li L, Yi AY (2009) Microfabrication on a curved surface using 3D microlens array projection. J Micromech Microeng 19(10):105010

Li L, Yi AY (2010) Development of a 3D artificial compound eye. Opt Express 18(17):18125–18137

Hsu WY, Liu YL, Cheng YC, Kuo CH, Chen CC, Su GD (2012) Design, fabrication, and metrology of ultra-precision optical freeform surface for progressive addition lens with B-spline description. Int J Adv Manuf Technol 63(1–4):225–233

Wang XS, Kang M, Fu XQ, Li CL (2013) Predictive modeling of surface roughness in lenses precision turning using regression and support vector machines. Int J Adv Manuf Technol. doi:10.1007/s00170-013-5231-3

Zhang XD, Fang FZ, Wu QQ, Liu XL, Gao HM (2012) Coordinate transformation machining of off-axis aspheric mirrors. Int J Adv Manuf Technol 67(9–12):2217–2224

Zhang XD, Fang FZ, Wang HB, Wei GS, Hu XT (2009) Ultra-precision machining of sinusoidal surfaces using the cylindrical coordinate method. J Micromech Microeng 19(5):054004

Turbo PMAC USER MANUAL, Programmable Multi Axis Controller, Delta Tau Data Systems, Inc. <http://www.deltatau.com> (2008) pp. 292–294

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Fu, X., Li, C. et al. Tool path generation for slow tool servo turning of complex optical surfaces. Int J Adv Manuf Technol 79, 437–448 (2015). https://doi.org/10.1007/s00170-015-6846-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-6846-3