Abstract

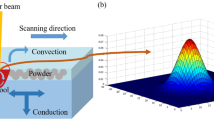

In order to achieve rapid manufacturing of tungsten-copper alloy part, copper alloy parts (CuW, CuSn, CuP, with mass ratio of 1:2:2) were manufactured by selective laser melting (SLM), and the influence of different energy input was investigated. The methodology of separating part model was adopted to overcome the manufacturing defects that was caused by the scanning strategy. The results shown that the thicknesses of the thin walls gained by SLM vary from 123 to 276 μm with the laser power varying from 100 to 120 W and the scanning speed of 200 to 700 mm/s. The compartment walls obtained through separating part model were of uniform thicknesses and nonclogging pores. It provides a feasible method for manufacturing precise parts containing tungsten and mass manufacturing of precise microcomponents by the SLM process.

Similar content being viewed by others

References

Yadroitsev I, Shishkovsky I, Bertrand P, Smurov I (2009) Manufacturing of fine-structured 3D porous filter elements by selective laser melting. Appl Surf Sci 255:5523–5527

Ameli M, Agnew B, Leung PS, Ng B, Sutcliffe C, Singh J, Mcglen R (2013) A novel method for manufacturing sintered aluminium heat pipes (SAHP). Appl Therm Eng 52:498–504

Ravi G, Hao X, Wain N, Wu X, Attallah M (2013) Direct laser fabrication of three dimensional components using SC420 stainless steel. Mater Des 47:731–736

Song C, Yang Y, Wang Y, Wang D, Yu J (2014) Research on rapid manufacturing of CoCrMo alloy femoral component based on selective laser melting. Int J Adv Manuf Technol 75:445–453

Vettivel SC, Selvakumar N, Leema N (2013) Experimental and prediction of sintered Cu–W composite by using artificial neural networks. Mater Design 45:323–335

Gao W, Wang Q, Yang Y, Fan Z (2010) Fabrication technology of tungsten copper composite for sputtering material. Rare Metal Mat Eng 39(5):892–895

Yang W, Zhou L, Peng K, Zhu J, Wan L (2013) Effect of tungsten addition on thermal conductivity of graphite/copper composites. Compos Part B 55:1–4

Meng Y, Shen Y, Chen C, Li Y, Feng X (2013) Microstructures and formation mechanism of W–Cu composite coatings on copper substrate prepared by mechanical alloying method. Appl Surf Sci 282:757–764

Duan L, Lin W, Wang J, Yang G (2014) Thermal properties of W–Cu composites manufactured by copper infiltration into tungsten fiber matrix. Int J Refract Met H 46:96–100

Abu-oqail A, Ghanim M, El-sheikh M, El-nikhaily A (2012) Effects of processing parameters of tungsten–copper composites. Int J Refract Met H 35:207–212

Mumtaz KA, Hopkinson N (2010) Selective laser melting of thin wall parts using pulse shaping. J Mater Process Tech 210:279–287

Zhang D, Cai Q, Liu J, He J, Li R (2013) Microstructural evolvement and formation of selective laser melting W–Ni–Cu composite powder. Int J Adv Manuf Technol 67:2233–2242

Gu D, Shen Y (2006) WC–Co particulate reinforcing Cu matrix composites produced by direct laser sintering. Mater Lett 60:3664–3668

Gu D, Shen Y (2008) Influence of Cu-liquid content on densification and microstructure of direct laser sintered submicron W–Cu/micron Cu powder mixture. Mater Sci Eng A 489:169–177

Gu D, SHEN Y (2009) Effects of processing parameters on consolidation and microstructure of W–Cu components by DMLS. J Alloy Compd 473:107–115

Li R, Shi Y, Liu J, Xie Z, Wang Z (2010) Selective laser melting W–10 wt.% Cu composite powders. Int J Adv Manuf Technol 48:597–605

Rehme O, Emmelmann C (2005) Reproducibility for properties of selective laser melting products. Proceedings of the Third International WLT-Conference on Lasers in Manufacturing, Munich

Su X, Yang Y, Xiao D, Luo Z (2013) An investigation into direct fabrication of fine-structured components by selective laser melting. Int J Adv Manuf Technol 64:1231–1238

Mumtaz K, Hopkinson N (2010) Selective laser melting of thin wall parts using pulse shaping. J Mater Process Technol 210:279–287

Wang D, Yang Y, Yi Z, Su X (2013) Research on the fabricating quality optimization of the overhanging surface in SLM process. Int J Adv Manuf Technol 65(9–12):1471–1484

Ciurana J, Hernandez L, Delgado J (2013) Energy density analysis on single tracks formed by selective laser melting with CoCrMo powder material. Int J Adv Manuf Technol 68(5–8):1103–1110

Tolochko NK, Mozzharov S, Yadroitsev I, Laoui T, Froyen L, Titov V, Ignatiev M (2004) Balling process during selective laser treatment of powders. Rapid Prototyping J 10(2):78–87

Elsen MV (2007) Complexity of selective laser melting: a new optimisation approach. Phd. Department of Mechanical Engineering. Katholieke Universiteit Leuven, Leuven

Yadroitsev I, Krakhmalev P, Yadroitsava I, Johansson S, Smurov I (2013) Energy input effect on morphology and microstructure of selective laser melting single track from metallic powder. J Mater Process Technol 213:606–613

Wang D, Yang Y, Su X, Chen Y (2012) Study on energy input and its influences on single-track, multi-track, and multi-layer in SLM. Int J Adv Manuf Technol 58(9–12):1189–1199

Wang D, Yang Y, Liu R, Xiao D, Sun J (2013) Study on the designing rules and processability of porous structure based on selective laser melting (SLM). J Mater Process Technol 213(10):1734–1742

Loh L , Liu Z , Zhang D, Yeong W, Chua C(2013) Effect of laser beam profile on melt track in Selective Laser Melting In: High Value Manufacturing: Advanced Research in Virtual and Rapid Prototyping: Proceedings of the 6th International Conference on Advanced Research in Virtual and Rapid Prototyping, CRC Press, Portugal, pp83

Kruth J, Froyen L, Van Vaerenbergh J, Mercelis P, Rombouts M, Lauwers B (2004) Selective laser melting of iron-based powder. J Mater Process Technol 149:616–622

Kruth J, Vandenbroucke B, Van Vaerenbergh J, Mercelis P (2005) Benchmarking of different SLS/SLM processes as rapid manufacturing techniques. Int. Conf. on Polymers &Mould Innovations (PMI), Gent, p 525

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Song, C., Yang, Y., Liu, Y. et al. Study on manufacturing of W-Cu alloy thin wall parts by selective laser melting. Int J Adv Manuf Technol 78, 885–893 (2015). https://doi.org/10.1007/s00170-014-6689-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6689-3