Abstract

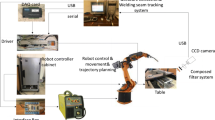

In this paper, an image-based visual servo control system is developed and integrated into a double head welding robot for CO2 gas shielded arc welding, which is mainly used to weld the narrow seam whose width is generally less than 0.2 mm. Firstly, a robust and reliable image processing algorithm is presented to reliably extract the seam feature during the welding. A statistic-based filter method is proposed to effectively weaken the image noises caused by various disturbances. The region of interest (ROI) of the image is determined to improve the efficiency and reliability of the image processing. The feature line of the narrow seam is extracted by combining the technique of the least-square line fitting with the Hough transform method. Secondly, a visual servo control system is designed to realize accurate tracking and initial point localization of the narrow seam. Moreover, an image error filter and output pulse verification are utilized to guarantee the reliability and stability of the control system. Finally, a series of experiments with real welding robots are conducted in the production line of a container manufacturing factory, demonstrating the satisfactory performance and high welding quality of the proposed visual servo control system.

Similar content being viewed by others

References

Heber M, Lenz M, Rüther M, Bischof H, Fronthaler H, Croonen G (2013) Weld seam tracking and panorama image generation for on-line quality assurance. Int J Adv Manuf Technol 65(9–12):1371–1382

Pan ZX, Polden J, Larkin N, Duin SV, Norrish J (2012) Recent progress on programming methods for industrial robots. Robot Comput Integr Manuf 28(2):87–92

Bi ZM, Lang SY (2007) A framework for CAD- and sensor-based robotic coating automation. IEEE Trans Ind Inform 3(1):84–91

Chen SB, Qiu T (2004) Intelligentlized technologies for robotic welding. Ser Lect Notes Control Inf Sci 299:123–143

Xu D, Fang ZJ, Chen HY, Yan ZG, Tan M (2012) Compact visual control system for aligning and tracking narrow butt seams with CO2 gas-shielded arc welding. Int J Adv Manuf Technol 62(9–12):1157–1167

Kim JY (2007) CAD-based automated robot programming in adhesive spray systems for shoe out soles and uppers. J Robot Syst 21:625–634

Bae KY, Park JH (2006) A study on development of inductive sensor for automatic weld seam tracking. Mater Process Technol 76(1–3):111–116

Eskandari S, Arezoo B, Abdullah A (2013) Positional, geometrical, and thermal errors compensation by tool path modification using three methods of regression, neural networks, and fuzzy logic. Int J Adv Manuf Technol 65(9–12):1635–1649

Gao XD, Na SJ (2005) Detection of weld position and seam tracking based on Kalman filtering of weld pool images. J Manuf Syst 24(10):1–12

Ge JG, Zhu ZQ, He DF, Chen LQ (2005) A vision-based algorithm for seam detection in a PAW process for large-diameter stainless steel pipes. Int J Adv Manuf Technol 26(9–10):1006–1011

Kuo HC, Wu LJ (2002) An image tracking system for welded seams using fuzzy logic. Mater Process Technol 120(1–3):169–185

Tsai MJ, Lee HW, Ann NJ (2011) Machine vision based path planning for a robotic golf club head welding system. Robot Comput Integr Manuf 27(4):843–849

Ma H, Wei S, Sheng Z, Lin T, Chen SB (2009) Robot welding seam tracking method based on passive vision for thin plate closed-gap butt welding. Int J Adv Manuf Technol 48(9–12):945–953

Mahajan A, Figueroa F (2007) Intelligent seam tracking using ultrasonic sensors for robotic welding. Robotica 15(3):275–281

Wilson WJ, Hulls CC, Bell GS (1996) Relative end-effector control using Cartesian position-based visual servoing. IEEE Trans Robot Autom 12(5):684–696

Mariottini GJ, Oriolo G, Prattichizzo D (2007) Image-based visual servoing for nonholonomic mobile robots using epipolar geometry. IEEE Trans Robot 23(1):87–100

Allibert G, Courtial E, Chaumette F (2010) Predictive control for constrained image-based visual servoing. Robot IEEE Trans 26(5):933–939

Graaf M, Aartsa A, Jonkera B, Meijera J (2010) Real-time seam tracking for robotic laser welding using trajectory-based control. Control Eng Pract 18(8):1–10

Zhang WZ, Chen Q, Zhang GX, Sun ZG, Du D (2007) Seam tracking of articulated robot for laser welding based on visual feedback control. Rob Weld Intell Autom Lect Notes Control Inf Sci 362:281–287

Özcan M (2011) Determining seam profile tracking of very narrow butt welding on sheet metal. Sci Res Essays 6(23):5040–5048

Dinham M, Fang G (2013) Autonomous weld seam identification and localisation using eye-in-hand stereo vision for robotic arc welding. Robot Comput Integr Manuf 29(5):288–301

Ye Z, Fang G, Chen SB, Zou JJ (2013) Passive vision based seam tracking system for pulse-MAG welding. Int J Adv Manuf Technol 67(9–12):1987–1996

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, H., Liu, K., Xing, G. et al. A robust visual servo control system for narrow seam double head welding robot. Int J Adv Manuf Technol 71, 1849–1860 (2014). https://doi.org/10.1007/s00170-013-5593-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5593-6