Abstract

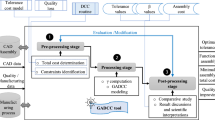

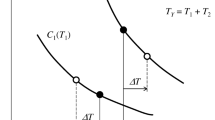

This paper presents a new approach to the tolerance synthesis of the component parts of assemblies by simultaneously optimizing three manufacturing parameters: manufacturing cost, including tolerance cost and quality loss cost; machining time; and machine overhead/idle time cost. A methodology has been developed using the genetic algorithm technique to solve this multi-objective optimization problem. The effectiveness of the proposed methodology has been demonstrated by solving a wheel mounting assembly problem consisting of five components, two subassemblies, two critical dimensions, two functional tolerances, and eight operations. Significant cost saving can be achieved by employing this methodology.

Similar content being viewed by others

References

Lee WJ, Woo TC (1989) Optimum selection of discrete tolerances. T ASME J Mech Transmissions Autom Des 111:243–251

Chase KW, Greenwood WH, Loosli BG, Hauglund LF (1990) Least cost tolerance allocation for mechanical assemblies with automated process selection. Manuf Rev 3(1):49–59

Zhang C, Wang HP (1993) The discrete tolerance optimization problem. Manuf Rev 6(1):60–71

Sangeet Uttam (2001) Optimal tolerance synthesis for process selection with machine selection. M.S. Thesis, University of Cincinnati.

Nagarwala MY, Simin Pulat P, Raman S (1995) A slope-based method for least cost tolerance allocation. Concurr Eng 3(4):319–328

Feng CXJ, Kusiak A (2000) Robust tolerance synthesis with the design of experiments approach. J Manuf Sci Eng 122(3):520–528

Ming XG, Mak KL (2001) Intelligent approaches to tolerance allocation and manufacturing operations selection in process planning. J Mater Process Technol 117(1–2):75–83

Ye B, Salustri FA (2003) Simultaneous tolerance synthesis for manufacturing and quality. Res Eng Des 14(2):98–106

Jeang A, Chang CL (2002) Combined robust parameter and tolerance design using orthogonal arrays. Int J Adv Manuf Technol 19(6):442–447

Singh PK, Jain PK, Jain SC (2004) A genetic algorithm based solution to optimal tolerance synthesis of mechanical assemblies with alternative manufacturing processes: focus on complex tolerancing problems. Int J Prod Res 42(24):5185–5215

Singh PK, Jain SC, Jain PK (2004) A genetic algorithm based solution to optimum tolerance synthesis of mechanical assemblies with alternate manufacturing processes—benchmarking with the exhaustive search method using the lagrange multiplier. Proc IMechE, Part B Journal of Engineering Manufacture 218(B7):765–778

Kenneth W Chase (1999a) ‘Minimum cost tolerance allocation’, ADCATS Report No. 99–5, Department of Mech. Engg., Brigham Young University

Dilplaris SC, Sfantsikopoulos P (2001) Cost–tolerance function: a new approach for cost optimum machining accuracy. Int J Adv Manuf Technol 16(1):32–38

Monica Carfagni, Lapo Governi, Francesco Fhiesi (2001) Development of a method for automatic tolerance allocation, Proceeding of the XII ADM International Conference, Italy, D1-20–D1-27.

Ji S, Li X, Ma Y, Cai H (2000) Optimal tolerance allocation based on fuzzy comprehensive evaluation and genetic algorithm. Int J Adv Manuf Technol 16(7):461–468

Prabhaharan G, Asokan P, Ramesh P, Rajendran S (2004) Genetic-algorithm-based optimal tolerance allocation using a least-cost model. Int J Adv Manuf Technol 24(9–10):647–660

Singh PK, Jain SC, Jain PK (2005) Advanced optimal tolerance design of mechanical assemblies with interrelated dimension chains and process precision limits. Comput Ind 56(2):179–194

Chou CY, Chang CL (2001) Minimum-loss assembly tolerance allocation by considering product degradation and time value of money. Int J Adv Manuf Technol 17(2):139–146

Yang CC, Achuthanaikan VN (2003) Optimum tolerance design for complex assemblies using hierarchical interval constraint networks. Comput Ind Eng 45(3):511–543

Rao S, Wu W (2005) Optimum tolerance allocation in mechanical assemblies using an interval method. Eng Optim 37(3):237–257

Savage GJ, Tong D, Carr SM (2005) Optimal mean and tolerance allocation using conformance-based design. Qual Reliab Eng Int 22(4):445–472

Prabhaharan G, Asokan P, Rajendran S (2005) Sensitivity-based conceptual design and tolerance allocation using the continuous ants colony algorithm (CACO). Int J Adv Manuf Technol 25(5–6):516–526

Huang YM, Shiau CS (2006) Optimal tolerance allocation for a sliding vane compressor. J Mech Des 128(1):98–107

GopalaKrishnan B, Jaraiedi M, Iskander WH, Ahmad A (2007) Tolerance synthesis based on Taguchi philosophy. Int J Ind Syst Eng 2(3):331–326

Dantan JY, Bruyere J, Vincent JP, Bigot R (2009) Vectorial tolerance allocation of bevel gear by discrete optimization. Mechanism and Machine Theory 43:1478–1494

Etienne A, Dantan JY, Qureshi J, Siadat A (2008) Variation management by functional tolerance allocation and manufacturing process selection. Int J Interact Des Manuf 2(4):207–218

Wua F, Dantan JY, Etienne A, Siadat A, Martin P (2009) Improved algorithm for tolerance allocation based on Monte Carlo simulation and discrete optimization. Comput Ind Eng 56:1402–1413

Huanmin Xu Ã, Li D (2009) Modeling of process parameter selection with mathematical logic for process planning. Robotics and Computer-Integrated Manufacturing 25(3):529–535

Sivakumar K , Balamurugan C, Ramabalan S, Venkata Raman SB (2009) Optimal concurrent dimensional and geometrical tolerancing based on evolutionary algorithms, World Congress on Nature & Biologically Inspired Computing (NaBIC 2009), 300–305

Sivakumar K, Balamurugan C, Ramabalan S (2010) Concurrent multi-objective tolerance allocation of mechanical assemblies considering alternative manufacturing process selection. Int J Adv Manuf Technol 53(5–8):711–732

Janakiraman V, Saravanan R (2010) Concurrent optimization of machining process parameters and tolerance allocation. Int J Adv Manuf Technol 51(1–4):357–369

Sivasubramanian R, Siva Kumar M (2010) Optimum tolerance synthesis with process and machine selection for minimizing manufacturing cost and machining time by using genetic algorithm. Journal of Manufacturing Technology Research 2(1–2):93–108

Rao YS (2011) Simultaneous tolerance synthesis for manufacturing and quality using evolutionary algorithms. International Journal of Applied Evolutionary Computation (IJAEC) 2(2):1–20

Cheng KM, Tsai JC (2011) Optimal statistical tolerance allocation of assemblies for minimum manufacturing cost. Applied Mechanics and Materials 52–54:1818–1823

Hung TC, Chan KY (2012) Multi-objective design and tolerance allocation for single and multi-level systems. J Intell Manuf. doi:10.1007/s10845-011-0608-3

Gadallah MH (2011) Least sensitive tolerance allocation. International Journal of Quality Engineering and Technology 2(4):344–356

Jayaprakash G, Sivakumar K, Thilak M (2012) FEA compliant parametric tolerance allocation of mechanical assembly using neural network and differential evolution algorithm. Int J Comput Integr Manuf. doi:10.1080/0951192X.2012.665184

Lööf J, Söderberg R (2012) Discrete tolerance allocation for product families. Eng Optim 44(1):75–85

Rajesh S, Toshihiro T, Koji I, Nobuhiro S (2008) A study on integration of process planning and scheduling system for holonic manufacturing with modification of process plans. Int J Manuf Technol Manag 14(3/4):359–378

Li X, Gao L, Shao X, Zhang C, Wang C (2010) Mathematical modeling and evolutionary algorithm-based approach for integrated process planning and scheduling. Comput Oper Res 37(4):656–667

Li WD, Gao L, Li XY, Guo Y (2008) Game theory-based cooperation of process planning and scheduling. In: Proceeding of CSCWD. IEEE Press, New York, pp 841–845

Guo YW, Li WD, Mileham AR, Owen GW (2009) Applications of particle swarm and optimization in integrated process planning and scheduling. Robotics and Computer-Integrated Manufacturing 25:280–288

Hengyun Z, Wenhua Y, Guangxia B (2009) A particle swarm optimization for integrated process planning and scheduling. International Conference on Computer-Aided Industrial Design & Conceptual Design, CAID & CD 2009:1070–1074

Li X, Gao L, Zhang G, Zhang C, Shao X (2008) A genetic algorithm for integration of process planning and scheduling problem. In: Xiong C et al (eds) ICIRA 2008, Part II, LNAI 5315., pp 495–502

Li X, Shao X, Gao L, Qian W (2010) An effective hybrid algorithm for integrated process planning and scheduling. Int J Prod Econ 126(2):289–298

Liana K, Zhanga C, Gaoa L, Lia X (2011) Integrated process planning and scheduling using an imperialist competitive algorithm. Int J Prod Res. doi:10.1080/00207543.2011.622310

Rakesh K, Phandena AJ, Rajiv V (2011) Integration of process planning and scheduling: a state-of-the-art review. Int J Comput Integr Manuf 24(6):517–534

Li WD, McMahon CA (2007) A simulated annealing-based optimization approach for integrated process planning and scheduling. Int J Comput Integr Manuf 20(1):80–95

Taguchi G, Elsayed EA, Hsiang TC (1989) Quality engineering in production systems. McGraw-Hill book Co., New York

Huang YM, Shiau CS (2006) Optimal tolerance allocation for a sliding vane compressor. Journal of Mechanical Design—Transactions of the ASME 128:98–107

Sampath kumar R, Alagumurthi N, Ramesh R (2009) Optimization of design tolerance and asymmetric quality loss cost using pattern search algorithm. International Journal of Physical Sciences 4(11):629–637

Huang YM, Shiau CS (2009) An optimal tolerance allocation model for assemblies with consideration of manufacturing cost, quality loss and reliability index. Assem Autom 29(3):220–229

Muthu P, Dhanalakshmi V, Sankaranarayanasamy K (2010) Design and manufacturing tolerances optimization with quality loss functions. International Journal of Advanced Operations Management 2(1/2):90–107

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Geetha, K., Ravindran, D., Kumar, M.S. et al. Multi-objective optimization for optimum tolerance synthesis with process and machine selection using a genetic algorithm. Int J Adv Manuf Technol 67, 2439–2457 (2013). https://doi.org/10.1007/s00170-012-4662-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4662-6