Abstract

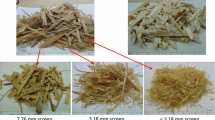

This study is first in a series investigating the combination of Moso bamboo (Phyllostachys pubescens Mazel) and aspen (Populus tremuloides Michx.) to fabricate hybrid strand based panel composites. Here the wood and bamboo strands were evenly mixed together to form a thin, uni-directional strandboard 10 mm in thickness. The use of 30 % aspen strands was to improve the compaction and consolidation of the hard, uncompressible bamboo. The effects of replacing most of the aspen strands (70 %) with bamboo strands on board strength properties (IB, MOR, MOE) and moisture resistance were assessed. The effect of strands cut from the node free (internode) or node tissue portions of the culm on board properties was also systematically investigated. Substitution with 70 % internode Moso bamboo strands increased MOR by over 40 % compared with pure aspen and significantly lowered thickness swell and water absorption. Substituting aspen with the bamboo strands resulted in no change in MOE, in keeping with the tendency for natural Moso bamboo tissue to be high in bending strength and fracture toughness but lower in specific stiffness. The presence of node tissue in the bamboo strands significantly reduced the consolidation and mechanical properties of the composites.

Similar content being viewed by others

References

Amada S, Untao S (2001) Fracture properties of bamboo. Compos B 32:451–459

Amada S, Ichikawa Y, Munekata T, Nagase Y, Shizu Y (1997) Fiber texture and mechanical graded structure of bamboo. Composites B 28:13–20

Andrews CK (1998) The influence of furnish moisture content and press closure rate on the formation of the vertical density profile in oriented strand board: relating the vertical density profile to bending properties, dimensional stability and bond performance. MSc Thesis, The University of Tennessee, Knoxville, TN

Andrews CK, Winistorfer PM, Bennett RM (2001) The influence of furnish moisture content and press closure rate on the formation of the vertical density profile of oriented strand board. For Prod J 51(5):32–39

Andtbacka S (2005) A fibreline designed for bamboo pulping. TAPPSA Journal November 2005, p 13. http://www.tappsa.co.za/archive2/Journal_papers/Bamboo_pulping/bamboo_pulping.html. Accessed 5 July 2014

Anon (2010) Growing poplars for food security: millions benefit from poplar forests in China. Food and Agriculture Organisation of the United Nations Media News Article. http://www.fao.org/news/story/en/item/44518/icode/. Accessed 18 Nov 2013

Anon (2012) Aiming for domination. Wood based panels international online, 18 June 2012. http://www.wbpionline.com/features/aiming-for-domination/. Accessed 10 Apr 2013

Anon (2013) OSB demand in China predicted to grow; new board capacities to appear in China and India. Global Trends Review, 24 May 2013. http://whatwood.ru/english/global-trends-review-may-13-19-2013-osb-demand-in-china-predicted-to-grow-new-board-capacities-to-appear-in-china-and-india/. Accessed 3 Oct 2014

ASTM (2006) Standard test method for evaluating properties of wood-base fiber and particle panel materials-ASTM D 1037-06a. American Society for Testing and Materials International, West Conshohocken, p 30

Austin R, Ueda K (1970) Bamboo. Weather Hill Publishing, NY, p 211

Barbuta C, Blanchet P, Clouteir A (2012) Mechanical properties of unidirectional strand board (USB) with flat vertical density profile. J Mat Sci Res 1(3):42–49

Blomberg J, Persson B (2004) Plastic deformation in small clear pieces of scots pine (Pinus sylvestris) during densification with the CaLignum process. J Wood Sci 50(4):307–314

Blomberg J, Persson B, Bexell U (2006) Effects of semi-isotropic densification on anatomy and cell shape recovery on soaking. Holzforschung 60(3):322–331

Boeck F (2013) Personal communication of his own observations made during a visit to Yung LiFa bamboo OSB pilot plant, Yunnan Province, China in June 2012

Brochmann J, Edwardson C, Shmulsky R (2004) Influence of resin type and flake thickness on properties of OSB. For Prod J 54(3):51–55

Chen Y, Fan D, Quin T, Chu F (2014) Thermal degradation and stability of accelerated-curing phenol formaldehyde resin. Biores 9(3):4063–4075

Chin SW (2003) Evaluation on the manufacturing of structure bamboo laminated curved beams and related flexural properties. MSc Thesis, National Ping Tung University of Science and Technology (Taiwan), p 57

CSA (2011) Standards on OSB and waferboard- O437.0-93R. Canadian Standards Association, Toronto, p 88

Dagilis TD (1999) Bamboo composite materials for low-cost housing. PhD Thesis, Department of Civil Engineering, Queens University, Kingston, ON, p 229

Dai CP, Mei C, Korai H (2002) Density and property relationships of wood strand composites. In: Proceedings 6th Pacific Rim Bio-Based Composites Symposium, Nov. 10–13, Portland, Oregon, pp 458–466

De Flander K, Rovers R (2009) One laminated bamboo-frame house per hectare per year. Constr Building Mat 23(1):210–212

De Vos V (2010) Bamboo for exterior joinery: a research in material properties and market perspectives. BSc Thesis, University of Applied Sciences Van Hall Larenstein (Wageningen UR), p 82

Dixon PG, Gibson LJ (2014) The structure and mechanics of Moso bamboo material. J Roy Soc Interface 11:20140321. doi:10.1098/rsif.2014.0321

Freischmidt G, Blakemore P (2009) Potential applications of the native hardwood resource available to VicForests as wood composite products. CSIRO Report to VicForests No. CMSE(C)-2008-312, p 71

Frith O (2013) Personal communication of his knowledge of the bamboo processing industry made during a visit to Anji Province, China in April 2013

Fu W (2007a) Bamboo-A potential resource of raw material for OSB in China. China Forest Prod Ind 34:21–24

Fu W (2007b) A Study on Flaking Technique and Manufacture of Bamboo OSB. PhD Dissertation, Northeast Forestry University, Harbin, China. p 86

Grossenbacher M (2012) Industrial production of bamboo OSB: A technical report. (In German). In: 2nd Bieler Holzwerkstoff-Workshop, 28–29 November 2012, Biel, Switzerland

Harries K, Sharma B, Richard M (2012) Structural use of full culm bamboo: the path to standardization. Int J Arch Eng Constr 1(2):66–75

Hua Y, Zhou D (1996) The development of oriented strand board in China. In: Kajita H, Tsunoda K (eds) Proc 3rd Pacific Rim Bio-Based Composites Symposium, Dec 2–5, 1996. Kyoto, Japan, pp 64–71

Janssen JA (1981) Bamboo in building structures. PhD Dissertation, Eindhoven University of Technology, Netherlands

Jiang ZH (2002) Bamboo and rattan in the world. LiaoNing Science and Technology Publishing House, China

Kang KY, Bradic S, Avramidis S, Mansfield SD (2007) Kiln drying quality of lumber from poplar hybrid clones. Holzforschung 61(1):65–73

Kretschmann DE (2010) Chapter 5 mechanical properties of wood, in wood handbook: wood as an engineering material, USDA forest service forest products laboratory GTR 190. Forest Products Laboratory, Madison, p 509

Lee AWC, Bai X, Peralta N (1994) Selected physical and mechanical properties of giant timber bamboo (Phyllostachys bambusoides) grown in South Carolina. For Prod J 44(9):40–46

Leise W (1985) Anatomy and properties of Bamboo. Proceedings international bamboo workshop, October 6-14, 1985, Beijing, China. Chin Acad For, Beijing, pp 196–208

Leise W (1992) The structure of bamboo in relation to its properties and utilization. In: Bamboo and its use, international symposium on industrial use of bamboo, 7–11 Dec., 1992, Beijing, China. International Tropical Timber Organization/Chinese Academy Of Forestry

Leise W (1998) The anatomy of bamboo culms. INBAR Technical Report 18, International Network for Bamboo and Rattan, Beijing, pp 175–191

Li SH, Zeng QY, Xiao YL, Fu SY, Zhou BL (1995) Biomimicry of bamboo bast fibre with engineering composite materials. Mat Sci Eng C 3:125–130

Lo TY, Cui HZ, Leung HC (2004) The effect of fiber density on strength capacity of bamboo. Mat Lett 58(21):2595–2598

Low IM, Che ZY, Latella BA, Sim KS (2006) Mechanical and fracture properties of bamboo. Key Eng Mat 312(1):15–20

Malanit P, Barbu MC, Fruhwald A (2011) Physical and mechanical properties of oriented strand lumber made from an Asian bamboo (Dendrocalmus asper Backer). Eur J Wood Prod 69(1):27–36

Peng Z, Lu T, Li L, Liu X, Gao Z, Hu T, Yang X, Feng Q, Guan J, Weng Q, Fan D, Zhu C, Lu Y, Han B, Jiang Z (2010) Genome-wide characterization of the biggest grass, bamboo, based on 10,608 putative full-length cDNA sequences. BMC Plant Biol 10:116–129

Peters JJ, Bender DA, Wolcott MP, Johnson JD (1999) Flexural properties and utilization options for hybrid poplar clones. In: Proc ASAE/CSAE-SCGR Ann International Mtg, Toronto, Canada, 18–21 July 1999

Peters JJ, Bender DA, Wolcott MP, Johnson JD (2002) Selected properties of hybrid poplar clear wood and composite panels. For Prod J 52(5):45–54

SAS Institute, Inc. (2012) JMP Version 10: discovering JMP. SAS Institute Inc., Cary, p 154

Schott W (2006) Bamboo in the Laboratory. Online publication, 9 pp http://www.powerfibers.com/BAMBOO_IN_THE_LABORATORY.pdf. Accessed 27 Aug 2014

Semple KE, Kamke FA, Kutnar A, Smith GD (2013) ‘Exploratory thermal-hydro-mechanical modification (THM) of Moso bamboo (Phyllostachys pubescens Mazel).’ In: Medved S, Kutnar A (eds) Characterisation of Modified Wood in Relation to Wood Bonding and Coating Performance. Proc. Joint COST Conf FP0904 and FP1006, 16-18 Oct 2013, Rogla, Slovenia, University of Ljubljana Biotechnical Faculty, Ljubljana, pp 220–227

Semple KE, Smola M, Hoffman J, Smith GD (2014a) Optimising the stranding of Moso bamboo (Phyllostachys pubescens Mazel) culms using a CAE 6/36 disk flaker. In: Barnes M, Herian V (eds) Proc 57th international convention of society of wood science and technology, June 23–27, 2014. Zvolen, Slovakia, pp 257–269

Semple KE, Xian D, Smith GD (2014b) Reinforced core particleboard for improved screw-holding ability. Wood Fiber Sci 46(1):48–64

Shao ZP, Zhou L, Liu YM, Wu XM, Arnaud C (2010) Differences in structure and strength between internode and node sections of Moso bamboo. J Trop For Sci 22(2):133–138

Spelter H, Wang R, Ince P (1996) Economic feasibility of products from inland west small-diameter timber - Gen. Tech. Rep. FPL-GTR-92, USDA Forest Service, Forest Products Laboratory, Madison, WI, p 17 pp

Su X, Zhang B, Huang Q, Huang L, Zhang X (2003) Advances in tree genetic engineering in China. Proc. XII World Forestry Congress, September 21–28, 2003, Quebec City, Quebec. http://www.fao.org/docrep/article/wfc/xii/0280-b2.htm. Accessed 18 Nov 2013

Subiyanto B, Miyatake A, Tomoyuki H, Fujii T (1996) Production technology of superior strength timber (SST) from bamboo. In: Kajita H, Tsunoda K (eds) Proc 3rd Pacific Rim Bio-Based Composites Symposium, Dec 2–5, 1996, Kyoto, Japan, pp 470–478

Sumardi I, Suzuki S, Ono K (2006) Some important properties of strandboard manufactured from bamboo. For Prod J 56(6):59–63

Wang S, Winistorfer PM (2000) Fundamentals of the vertical density profile formation in wood composites. Part 2 Methodology of vertical density profile formation under dynamic condition. Wood Fiber Sci 32(2):220–238

Wang S, Winistorfer PM (2001) Flake compression behaviour in a resinless mat as related to dimensional stability. Wood Sci Technol 35(5):379–393

Wolcott MP, Kamke FA, Dillard DA (1990) Fundamentals of flakeboard manufacture: viscoelastic behavior of the wood component. Wood Fiber Sci 22(4):345–361

Wu Q, Piao C (1999) Thickness swelling and its relationship to internal bond strength loss of commercial oriented strand board Forest Prod. J. 49(7/8):50–55

Xu W, Winistorfer PM (1995) A procedure to determine thickness swell distribution in wood composite panels. Wood Fiber Sci 27(2):119–125

Semple KE, Zhang, PK, Smith GD (2015) Hybrid oriented strand boards made from Moso bamboo (Phyllostachys pubescens Mazel) and Aspen (Populus tremuloides Michx.): Species-separated three-layer boards. Eur J Wood Prod (In Press)

Zhang H, Du F, Zhang F, Liao Z, Ye X, Zheng Z, Wang W (2007) Research and development of production technology of bamboo waferboard and oriented strand board based on biological characteristics and timber adaptability. J Bamboo Res 26(2):43–48

Zhou D (1989) A study of oriented structural board made from hybrid poplar-effect of some factors on mechanical forming installation for orientation effectiveness. Holz Roh- Werkst 47(10):405–407

Zhou D (1990) A study of oriented structural board made from hybrid poplar-physical and mechanical properties of OSB. Holz Roh- Werkst 48(7–8):293–296

Zhou C, Smith GD, Dai C (2009) Characterizing hydro-thermal compression behavior of Aspen wood strands. Holzforschung 63(5):609–617

Acknowledgments

This study was funded through an NSCERC (National Science and Engineering Research Council) G8 Tri-Council grant. The authors gratefully acknowledge Mr John Hoffman, Forest Products Innovations (Western Division), for access to boil tank facilities and operation of the disk strander, and Mr Rick Fodor, Carmanah Design and Engineering, Inc., Surrey, BC for training and advice on setup and operation of the disk strander. Thank you very much also to Mr Jason Hutzkal, Momentive Specialty Chemicals, Edmonton, AB for supplying PF resin.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Semple, K.E., Zhang, P.K., Smola, M. et al. Hybrid Oriented Strand Boards made from Moso bamboo (Phyllostachys pubescens Mazel) and Aspen (Populus tremuloides Michx.): uniformly mixed single layer uni-directional boards. Eur. J. Wood Prod. 73, 515–525 (2015). https://doi.org/10.1007/s00107-015-0913-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-015-0913-1