Summaries

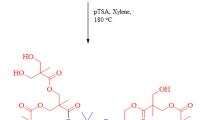

Hyperbranched polymers are a new class of polymeric material belonging to the group of macromolecules with highly branched structures and a large number of end groups. The structure of these polymers has a great impact on their physical and chemical properties. Many commercially-available chemicals can be used as the monomers in these systems, which should extend the availability and accessibility of hyperbranched polymers with various new end groups, architectures and properties. Because of their unique behaviour, hyperbranched polymers are suitable for a wide range of applications, especially for coatings.

This paper provides a concise review on molecular architecture and a general outline of methods to synthesise hyperbranched polymers and summarises their physico-chemical properties. The hyperbranched concept is discussed in terms of preparative methods, applications and advantages with respect to polymers for coatings. Hyperbranched polyesters, alkyds, epoxies, polyacrylates and siloxanes are discussed. Examples for other polymers such as polyurea, polyurethane dispersions (PUDs) and polyamides are also given.

Résumé

Les polymères hyperbranchés forment une nouvelle classe de matériau polymérique qui fait partie du groupe de macromolécules ayant une structure très branchée et beaucoup de groupes terminaux. La structure de ces polymères a un grand impact sur leurs propriétês physiques et chimiques. Beaucoup de produits qui sont disponibles dans le commerce peuvent être utilisés comme monomères dans ces systèmes qui devraient augmenter la disponibilité et l’accessibilité des polymères hyperbranchés ayant des groupes terminaux, une architecture et des propriétés nouveaux et variés. À cause de leur comportement unique, les polymères hyperbranchés sont convenables pour une grande variété d’applications, surtout pour les revétements.

Cet article fournit une étude concise d’architecture molaire et un résumé général des méthodes employées pour synthétiser les polymères hyperbranchés, aussibien qu’un résumé de leurs propriétés physico-chimiques. La conception « hyperbranché » est discutée vis-à-vis de méthodes de préparation, applications, et avantages réalisés dans le domaine des polymères pour revétements. Les alkydes, les époxies, les polyacrylates, et les siloxanes et les polyesters hyperbranchés sont discutés. On donne aussi des exemples ayant rapport à d’autres polymères tels que la polyurée, les dispersions polyuréthane (PUDs), et les polyamides.

Zusammenfassung

Extrem verzweigte Polymere sind eine neue Klasse von Polymermaterialien aus der Gruppe der Makromoleküle mit stark verzweigten Strukturen und vielen Endgruppen. Die Struktur dieser Polymere hat einen großen Einfluss auf ihre physikalischen und chemischen Eigenschaften. Viele kommerziell erhältliche Chemikalien können als Monomere in diesen Systemen verwendet werden, was die Erhältlichkeit von extrem verzweigten Polymeren mit neuen Endgruppen, Architekturen und Eigenschaften verbessern solite. Dank ihres einzigartigen Verhaltens sind extrem verzweigte Polymere für eine breite Palette von Anwendungen geeignet, insbesondere für Farben und Lacke.

Diese Arbeit vermittelt eine übersicht der molekularen Architekturen von extrem verzweigten Polymeren und präsentiert die allgemeinen Synthesemethoden und ihre physio-chemischen Eigenschaften. Das Konzept der Extremver zweigung wird mit Hinsicht auf Her stellungsmethoden. Applikationen und Vorteilen gegenüber anderen Polymeren für die Lackproduktion diskutiert Wit stellen extrem verzweigte Polyester, Alkyde. Epoxide, Polyacrylate und Siloxane vor, und geben Beispiele anderer Polymere wie Polyharnstoffe. Polyurethandispersionen (PUDs) und Polyamide.

Similar content being viewed by others

References

Klajnert B and B Maria, ‘Dendrimers: Properties and applications’,Acta Biochimica Polonica,48, (1), 198–208, 2001

Kim Y H and O W Webster, ‘Hyperbranched polyphenylenes’,Polym Prepr,29 (2), 310–1, 1988

Gao C and C Yan, ‘Hyperbranched polymers: From synthesis to applications’,Progress in Polymer Science,29, (3), 183–275, 2004

Pettersson B and K Sorensen, ‘The future of industrial coatings: Technical innovationvis a vis legislation’, Paper 21, 19, Proceedings of the PRA 15th International Conference, Brussels, 1995

Branko D, T Srba and B Branslav, ‘Dynamical mechanical analysis of photo-cross-linked hyperbranched urethane acrylates’,European Coatings Journal, (6), 36–41, 2004

Rogunova M, T-Y S Lynch, W Pretzer, M Kulzick, A Hiltner and E Baer, ‘Solid-state structure and properties of hyperbranched polyols’,Journal of Applied Polymer Science,77, 1207–17, 2002

Sunder A, J Heinemann and H Frey, ‘Controlling the growth of polymer trees: Concepts and perspectives for hyperbranched polymers’,Chem Eur J,6, (14), 2499–506, 2000

Sunder A, R Mülhaupt, R Haag and H Frey, ‘Hyperbranched polyether polyols. A modular approach to complex polymer architectures’,Advance Materials,12, (3), 2000

Flory P J, ‘Molecular-size distribution in three-dimensional polymers. IV. Branched polymers containing A-R-Bf21-type units’,J Am Chem Soc,74, 2718–23, 1952

Ramesh and Swaminathan, US Patent 6569956, 22nd December 1999

Komber H, A Ziemer and B Voit, ‘Etherification as side reaction in the hyperbranched polycondensation of 2,2 bis(hydroxymethyl)propionic acid’,Macromol,35, (9), 3514–9, 2002

Xu M, X Yan, R Cheng and X Yu, ‘Investigation into the solution properties of hyperbranched polymers’,Polym Internat,50, (12), 1338–45, 2001

Hult A, M Johansson and E Malmstrom, ‘The synthesis and properties of hyperbranched polyesters’,Macromol Symposia,98, 1159–61, 1995

Voit B, ‘Functional hyper-branched polyesters for application in blends, coatings and thin films’,Chem Eng Technol,25, (7), 704–7, 2002

Moens L (BE), K Buysens (BE) and D Maetens (BE), EP patent 1165714, 1st to 2nd September 2002

Vicari R (US), O S Fruchey (US), K N Juneau (US), S F Thames (US) and J W Rawlins (US), EP patent 1070748, 24th January 2001

Hong X, Q Chen, Y Zhang and G Liu, ‘Synthesis and characterisation of a hyperbranched polyol with long flexible chains and its application in cationic UV curing’,Appl Polym Sci, 9, (6), 1353–6, 2000

Malmstrom E, J Johnansson, A Jansson and A Hult, Proceedings from 26th International Water-borne, High-Solids and Powder Coatings Symposium, 373–82, New Orleans, USA, 1999

Frings B R and M Wend M, ‘New hyperbranched polyesters for UV curing’,DIC Technical Review, No 9, 43, 2003

Johansson M, M Malmstrom, A Jansson and A Hults, ‘A novel concept for low-temperature curing powder coatings based on hyperbranched polyesters’,J of Coating Technology,72, (906), July 2002

James D, ‘Performances of an acrylated dendritic polyester in a UV coating fomulations’, Perstorp Specialty Chemicals AB, Sweden Radtech 2001, Basel, Switzerland, 8th to 10th October 2001

Smanczyk K, K Manczyk, J Koziel and Konieczny, Proceedings from ‘Hungarocoat 99’, 176–89, Budapest, 1999

Van Dongen J, D Boekee, R Klaasen and P Bakker, Proceedings from PRA Advances in Exterior Wood Coatings and CEN Standardisation Conference, Paper 24, 18, Brussels, 1998

Manczyk K and P Szewczyk, ‘Highly branched high-solids alkyd resins’,Progr Org Coat,44, (2), 99–109, 2002

Dekker G, ‘Budding success story: The branching out of alkyd synthesis in low VOC paints, DSM Resins’,Polymer Paint Colour Journal,41, August 1999

Santing J A, A Hofland and L Grootoonk. Proceedings from XXIV FATIPEC Congress, A, A175-A190, Interlaken, Switzerland, 1998

Royappa A T, N Dalal and M W Giese, ‘Amphiphilic copolymers of glycidol with non-polar epoxide comonomers’,J Appl Polym Sci,82, (9), 2290–9, 2001

Emrick T, H-T Chang and J M J Frechet, ‘The preparation of hyperbranched aromatic and aliphatic polyether epoxies by chloride-catalysed proton transfer polymerisation from ABn and A2 + B3 monomers’,J Polym Sci, Polym Chem,38, 4850–69, (Supplement), 27th November 2000

Crivello J V and S Liu, ‘Photoinitiated cationic polymerisation of epoxy alcohol monomer’,J Polym Sci, Polym Chem,38, (3), 389–401, 2000

Boogh L, B Pettersson and Manson, ‘Dendritic hyperbranched polymers as tougheners for epoxy resins’,Polymer,40, 2249–61, 1999

Mezzenga R and J A E Manson, ‘Thermo-mechanical properties of hyperbranched polymer modified epoxies’,Journal of Material Science,36, 4883–91, 2001

Samuelsson J, P Sundell and M Johansson, ‘Synthesis and polymerisation of a radiation-curable hyperbranched resin based on epoxy functional fatty acids’,Progress in Organic Coatings,50, 193–8, 2004

Hong C-Y, C-Y Pan, Y Huang and Z-D Xu, ‘Synthesis of hyperbranched polymethacrylates in the presence of a tetrafunctional initiator’,Polymer,42, (16), 6733–40, 2001

Yoo S H, J H Lee, J-C Lee and J Y Jho, ‘Synthesis of hyperbranched polyacrylates in emulsion by atom transfer radical polymerisation’,Macromol,35, (4), 1146–8, 2002

Johansson M, G Rospo and A Hult,ACS,77, 124–5, Division of PMSE ACS Division of Polymeric Materials: Science and Engineering, 1999

Matyjaszewski K, J Pyun and S G Gaynor, ‘Preparation of hyperbranched polyacrylates by atom transfer radical polymerisation. 4. The use of zero-valent copper’,Macromol Rapid Comm,19 (12), 665–70, 1998

Ambade A V and A J Kumar, ‘Polym Science: An efficient route for the synthesis of hyperbranched polymers and dendritic building blocks based on urea linkages’,Polym Chem,39, (9), 1295–304, 2001

Davis N J and S P Rannard, G B patent 2324797, 4th November 1998

Dvornic P R, J Hu, D L Meier, R M Nowak and P L Parham, US patent 6534600, 26th March 2001

Gong C and J M J Fréchet, ‘End functionalisation of hyperbranched poly(siloxysilane): Novel cross-linking agents and hyperbranched-linear star block copolymers’,J Polym Sci, Polym Chem. 38, (16), 2970–8. 2000

Paulasaari J K and W P Weber, ‘Synthesis of hyperbranched polysiloxanes by base-catalysed protontransfer polymerisation. Comparison of hyperbranched polymer microstructure and properties to those of linear analogues prepared by cationic or anionic ring-opening polymerisation’,Macromol,33, (6), 2005–10, 2000

Muzafarov A M, N G Vasilenko, E A Rebrov, E V Getmanova and S B Rees, ‘Organosilicon dendrimers as a tools for new functional silicones synthesis’, Proceedings from PRA/Chemical and Polymer Silicones in Coatings III Conference, Paper 28, 8, Barcelona, Spain, 28th to 30th March 2000

Gong C, J Miravet and J M J Fréchet, ‘Synthesis of hyperbranched polysiloxanes by base-catalysed protontransfer polymerisation. Comparison of hyperbranched polymer microstructure and properties to those of linear analogues prepared by cationic or anionic ring-opening polymerisation’,J Polym Sci, Polym Chem,37, (16), 3193–201, 1999

Decker G T, D Gravier, Tselepis and A James, US patent 6001945 15th July 1998

Miravet J F and J M J Fréchet, ‘New hyperbranched poly(siloxysilanes): Variation of the branching pattern and end-functionalisation’,Macromol,31, (11), 3461–8, 1998

Gravier D (US), K A Quoc (US) and Binh T N (US), EP patent 857727 12th August 1998

Gao C and D Yan, ‘A2 + CBn approach to hyperbranched polymers with alternating ureido and urethano units’,Macromol,36, (3), 613–20, 2003

Versteegen R M, R P Sijbesma and E W Meijer, ‘Synthesis of [n]-polyurethanes and hyperbranched polyurethanes,’ACS Polym Preprints,40, (2), 839–40, 1999

Bruchmann B (DE), U Ehe (DE), F Wingerter (DE), K Stiefenhoefer (DE) and U Treuling (DE), EP patent 1026185, 9th August 2000

Kumar A and S Ramakrishnan, ‘Hyperbranched polyurethanes with varying spacer segments between the branching points’,J Polym Sci, Polym Chem,34, (5), 839–48, 1996

Van Benthem R A T M, N Meijerink, E Gelade, C G de Koster, D Muscat, P E Froehling, P H M Hendriks, C J A A Vermeulen and T J Zwartkruis, ‘Synthesis and characterisation of bis(2-hydroxypropyl)amide-based hyperbranched polyesteramides’Macromolecules,34, (11), 3559–66. 2001

Gelade E T F, B Goderis, C G de Koster, N Meijerink, R A T M van Benthem, R Fokkens, N M M Nibbering and K Mortensen, ‘Molecular structure characterisation of hyperbranched polyesteramides’,Macromol,34, (11), 3552–8, 2001

Yeske P E (US), L K Gindin (US), D A Wicks (US) and E H Jonsson (US), EP patent 743335, 20th November 1996

Vicari R (US), O S Fruchey (US), K N Juneau (US), S F Thames (US) and J W Rawlins (US), EP patent 1070748, 24th January 2001

Van Benthem R A T M, Proceedings from XXVth International Conference on Organic Coatings, Water-borne, High-Solids and Powder Coatings, 345–61, Vouliagmeni, Athens, Greece, 1999

Kaneko R, M Jikei and M Kakimoto, ‘Preparation and properties of photosensitive polymers based on hyperbranched aromatic polyamides’,High Performance Polymers,14, 53–62, 2002

Bruchmann B, Polymer research, BASF

Mori H, D C Seng, M Zhang and A H E Muller, ‘Hybrid nanoparticles with hyperbranched polymer shells via self-condensing atom transfer radical polymerisation from silica surfaces’,Langmuir,18, (9), 3682–93, 2002

Bolton D H and K L Wooley, ‘Hyperbranched aryl polycarbonates derived from A2B monomers vs AB2 monomers’,J Polym Sci, Part A: Polym Chem,40, (7), 823–35, 2002

Staring E, A A Dias and R A T M van Benthem, ‘New challenges for R&D in coating resins’,Progress in Organic Coatings,45, (2), 101–17, October 2002

Yan D, J Hou ‘Preparation of hyperbranched polyacrylates by atom transfer radical polymerisation: 4. The use of zero-valent copper’,Macromol Rapid Commun,21, 557–661, 2000

Voit B, ‘New developments in hyperbranched polymers’,Journal of Polymer Science Part A: Polymer Chemistry,38, (14), 2505–25, 15th July 2000

Skaria S, M Smet and H Frey, ‘A new approach to control crystallinity of resulting polymers: Self-condensing ring opening polymerization’,Macromolecular Rapid Communications,21, (9), 557–61, 2000

Park Y, J Lee and J Jin, ‘Hyperbranched LCPs’,Bull Korean Chem Soc,23, (9), 1201, 2002

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mehta, P. Hyperbranched polymers: unique design tool for coatings. Surface Coatings International Part B: Coatings Transactions 89, 333–342 (2006). https://doi.org/10.1007/BF02765586

Issue Date:

DOI: https://doi.org/10.1007/BF02765586