Abstract

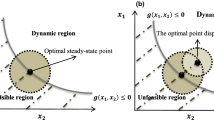

A comprehensive parametric study for a Fischer-Tropsch (FT) synthesis process has been conducted to investigate the relation between process parameters and reactor characteristics such as conversion, selectivity, multiplicity, and stability. A flexible model was employed for this purpose, featuring the dependence of Anderson-Shultz-Flory (ASF) factor on composition and temperature. All variable process parameters in industrial FT reactors were subject to variation, including reaction temperature, reactor pressure, feed ratio, inlet mass flux, feed temperature, heat transfer coefficient, catalyst concentration, catalyst activity, etc. While typical trade-off was encountered in most cases, i.e., the change of a parameter in one direction enhances one aspect but deteriorating another, the change of feed conditions gave some promising results. It has been found that decreasing the feed rate (or increasing the residence time) and/or lowering the feed concentration can successfully enhance the conversion up to more than 90% for our specific case, without hurting the product selectivity as well as effectively condense the region of multiple steady states. The benefits and limitations accompanied with the variation of the parameters were discussed in detail and a rational start-up strategy was proposed based on the preceding results. It is shown that the decrease of inlet mass flux (say, 85% decrease of the feed rate or 60% decrease of the feed concentration from the nominal condition chosen here) or the decrease of H2/CO ratio (specifically, below about 0.25), or their combination can eliminate multiple steady states. The resulting unique relation between temperature and manipulated variable (i.e., coolant flow rate) appears to assure a safe arrival at the target condition at the start-up stage.

Similar content being viewed by others

References

Adesina, A.A., “Hydrocarbon Synthesis via Fischer-Tropsch Reaction: Travails and Triumphs,”Appl. Catal. A: General,138, 345 (1996).

Adesina, A. A., Hudgins, R. R. and Silveston, P. L., “Fischer-Tropsch Synthesis Under Periodic Operation,”Catal. Today,25, 127 (1995).

Barshad, Y. and Gulari, E., “Modification of Product Distribution Through Periodic Operation: Fischer-Tropsch Synthesis Over Ru/ Al2O3,”Chem. Eng. Commun.,43, 39 (1986).

Bhattacharjee, S., Tierney, J.W. and Shah, Y. T., “Thermal Behavior of a Slurry Reactor: Application to Synthesis Gas Conversion,”Ind. Eng. Chem. Process Des. Dev.,25, 117 (1986).

Kirillov, V.A., Khanaev, V. M., Meshcheryakov, D., Fadeev, S. I. and Lukyanova, R.G., “Numerical Analysis of Fischer-Tropsch Processes in Reactors with a Slurried Catalyst Bed,”Theor. Found. Chem. Eng.,33, 270 (1999).

Lox, E. S. and Froment, G. F., “Kinetics of the Fischer-Tropsch Reaction on a Precipitated Promoted Iron Catalysts. 2. Kinetic Modeling,”Ind. Eng. Chem. Res.,32, 71 (1993).

Maretto, C. and Krishna, R., “Modelling of a Bubble Column Slurry Reactor for Fischer-Tropsch Synthesis,”Catal. Today,52, 279 (1999).

Russo, L. P. and Bequette, B.W., “Impact of Process Design on the Multiplicity Behavior of a Jacketed Exothermic CSTR,”AIChE J.,41, 135 (1995).

Shah, Y. T., Dassori, C.G. and Tierney, J.W., “Multiple Steady States in Non-isothermal FT Slurry Reactor,”Chem. Eng. Commun.,88, 49 (1990).

Sie, S. T., “Process Development and Scale Up: IV. Case History of the Development of a Fischer-Tropsch Synthesis Process,”Rev. Chem. Eng.,14, 109 (1998).

Song, H.-S., Ramkrishna, D., Trinh, S. and Wright, H., “Diagnostic Nonlinear Analysis of Fischer-Tropsch Synthesis in Stirred Tank Slurry Reactors,”AIChE J.,49, 1803 (2003a).

Song, H.-S., Ramkrishna, D., Trinh, S., Espinoza, R. L. and Wright, H., “Multiplicity and Sensitivity Analysis of Fischer-Tropsch Bubble Column Slurry Reactors: Plug-Flow Gas and Well-Mixed Slurry Model,”Chem. Eng. Sci.,58, 2759 (2003b).

Stern, D., Bell, A. T. and Heinemann, H., “A Theoretical Model for the Performance of Bubble-Column Reactors Used for Fischer-Tropsch Synthesis,”Chem. Eng. Sci.,40, 1665 (1985).

Van Der Vaan, G. P. and Beenackers, A. A. C. M., “Kinetics and Selectivity of the Fischer-Tropsch Synthesis: A Literature Review,”Catal. Rev. Sci. Eng.,41, 255 (1999).

Withers, H. P., Eliezer, K. F. and Mitchell, J.W., “Slurry-Phase Fischer-Tropsch Synthesis and Kinetic Studies over Supported Cobalt Carbonyl Derived Catalysis,”Ind. Eng. Chem. Res.,29, 1807 (1990).

Yermakova, A. and Anikeev, V. I., “Thermodynamic Calculations in the Modeling of Multiphase Processes and Reactors,”Ind. Eng. Chem. Res.,39, 1453 (2000).

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper is dedicated to Professor Hyun-Ku Rhee on the occasion of his retirement from Seoul National University.

Rights and permissions

About this article

Cite this article

Song, HS., Ramkrishna, D., Trinh, S. et al. Operating strategies for Fischer-Tropsch reactors: A model-directed study. Korean J. Chem. Eng. 21, 308–317 (2004). https://doi.org/10.1007/BF02705414

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02705414