Abstract

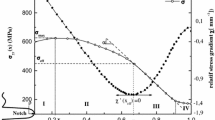

The Small-Scale Steady State (S4) test has been recently developed in order to assess the fracture behaviour of polyethylene (PE) gas distribution pipe material during rapid axial crack propagation. Based on an investigation of the S4 test, a simulation model of S4 test has been developed. This paper describes the use of the results obtained from the S4 test and program modified from PFRAC (Pipeline Fracture Analysis Code) to evaluate the fracture toughness of the material,G, which could not be directly obtained from the test, and to predict critical pressure,p c , for rapid crack propagation (RCP) in a full scale PE pipe. The algorithms for contact conditions are developed to consider the opening pipe wall impact against a series containment rings and the capabilities of PFRAC are also extended. WhenG d is evaluated, investigations are made on the effect of temperature, wall thickness and crack velocity. In addition, procedures to evaluate the critical pressure for the S4 test pipe are also discussed.

Similar content being viewed by others

References

Kanninen MF, Leung CP, O'Donoghue PE et al. Joint final report on the development of a ductile pipe fracture model. Submitted to Pipeline Research Committee,. AMERICAN GAS ASSOCIATION, Arlington, Virginia, July, 1992

Vanspeybroeck P. New test methods to evaluate the resistance to rapid crack propagation in pressurized polyethylene pipes. Proceedings of Plastics Pipes Eight, D1/6, Netherlands, 1992

Vanspeybroeck P. Evaluation of the correlation between instrumented charpy V tests and the modified robertson test for characterization of their resistance to rapid crack propagation in presurized polyethylene pipes. Proceedings of Pipeline Technology Conference, Belgium, October, 1990

O'Donoghue PE, Green ST, Kanninen MF, Bowles PK. The development of fluid/structure interaction model for flawed fluid containment boundaries with applications to gas transmission and distribution piping.Computers & Structures, 1991, 38(5/6): 501–513

Zhuang Z. The development of finite element methods for the investigation of dynamic crack propagation in gas pipelines: [Ph. D. thesis]. Ireland, Dublin: University College Dublin Ireland, 1995

Leevers PS, Yayla P. A new small scale test for rapid crack propagation. Proceedings Eleventh Plastic Fuel Gas Pipes Symposium, San Francisco, California, October, 1989

Zhuang Z, O'Donoghue PE. Design of Mechanical Crack Arrestors in Gas Pipelines. In: Topping BHV ed, Advances in Computational Methods for Simulation, Edinburgh: Civil-Comp Press, 1996, 239–245

Kanninen MF, O'Donoghue PE, Leung CP, et al. A fracture mechanics methodology for preventing rapid crack propagation in PE gas distribution pipes. Proceedings of Twelfth Plastic Fuel Gas Pipe Symposium, Boston Massachusetts, USA, September, 1991

Kanninen MF, Popelar CH. Advanced Fracture Mechanics. New York: Oxford University Press, 1985

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zhuo, Z., O'Donoghue, P.E. Material fracture toughness determination for polyethylene pipe materials using small scale test results. Acta Mech Sinica 13, 63–80 (1997). https://doi.org/10.1007/BF02487832

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02487832