Abstract

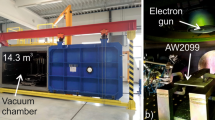

Lithium-containing aluminium alloys are of considerable current interest in the aerospace and aircraft industries because lithium additions to aluminium improve the modulus and decrease the density compared to conventional aluminium alloys. Few commercial aluminium-lithium alloys have emerged for use in the aerospace industry. One such candidate is 8090, a precipitation-hardenable Al-Li-Cu-Mg alloy. The influence of electron-beam welding on the microstructure and mechanical properties of alloy 8090 material has been evaluated through microscopical observations and mechanical tests. Microscopic observations of the electronbeam welds revealed an absence of microporosity and hot cracking, but revealed presence of microporosity in the transverse section of the weld. Mechanical tests revealed the electronbeam weld to have lower strength, elongation and joint efficiency. A change in microscopic fracture mode was observed for the welded material when compared to the unwelded counterpart. An attempt is made to rationalize the behaviour in terms of competing mechanistic effects involving the grain structure of the material, the role of matrix deformation characteristics, grain-boundary chemistry and grain-boundary failure.

Similar content being viewed by others

References

E. J. Lavernia, T. S. Srivatsan and F. A. Mohammed, J. Mater. Sci. 25 (1990) 1137.

John Mack, Mater. Engng 7 (1988) 2.

P. A. Molian and T. S. Srivatsan, J. Mater. Sci. 25 (1990) 3347.

T. H. Sanders Jr and E. A. Starke Jr (eds), “Aluminium-Lithium Alloys I”, Proceedings of the First International Conference (Metallurgical Society, Warrendale, PA, 1983) p. 507.

Idem T. H. Sanders Jr. E. A. Starke Jr, “Aluminium-Lithium Alloys II”, Proceedings of the Second International Conference (Metallurgical Society, Warrendale, PA, 1985).

S. J. Harris, C. J. Peel and P. J. Gregson (eds), “Aluminium-Lithium Alloys III”, Proceedings of Third International Conference (Institute of Metals, London, 1987).

C. Champier, D. Dubost, S. F. Miannay and L. Sabetay (eds), “Aluminium-Lithium Alloys IV”, Proceedings of the Fourth International Conference, J. de Phys. Coll., Vol. 3:6 France. 1987.

E. A. Starke Jr, T. H. Sanders Jr and I. G. Palmer, J. Metals, 12 (1981) 24.

P. J. Gregson and H. M. Flower, Acta Metall. 33 (1985) 527.

T. S. Srivatsan and E. J. Lavernia, J. Mater. Sci. 26 (1991) 940.

E. S. Balmuthu and R. Schmidt, “Aluminium-Lithium Alloys I”, edited by T. H. Sanders Jr and E. A. Starke Jr (Metallurgical Society, Warrendale, PA, 1981) pp. 69–75.

J. R. Pickens, J. Mater. Sci. 20 (1983) 4247.

J. R. Pickens, F. H. Neubaum, T. J. Langan and L. S. Kramer, in “Aluminium-Lithium Alloys V”, Proceedings of Fifth International Conference, edited by E. A. Starke Jr and T. H. Sanders Jr (Materials Component and Engineering Publications, Birmingham, UK, 1989) p. 1397.

T. S. Srivatsan and T. S. Sudarshan, Weld. J. July (1991) 173-s.

M. H. Skillingberg, in “Aluminium Technology '86”, Proceedings of the Conference (Institute of Metals, London, 1986) p. 507.

D. M. Bowden and P. J. Meschter, Scripta Metall. 18 (1984) 963.

Le Poac, A. M. Nomine and D. Miannay, in “Aluminium-Lithium Alloys I”, Proceedings of Fourth International Conference, J. de Phys. Coll., Vol. 3:6 dedited by G. Champier, B. Dubost, D. Miannay and C. Sabetay (1987) p. 293.

D. S. Gnanamuthu and R. J. Moores, in “Proceedings of Conference of Power Beam Processing” (ASM International, Metals Park, OH, 1988) p. 181.

M. R. Edwards, E. Klinkin and V. E. Stoneham, in “Aluminium-Lithium Alloys V”, Proceedings of Fifth International Conference, edited by T. H. Sanders Jr and E. A. Strake Jr (Materials and Component Engineering Publications, Birmingham, UK, 1989) p. 431.

J. A. Bishop, D. Jobling and G. E. Thompson, in “International Conference on Advances in Joining and Cutting Processes”, Abington, Cambridge, UK (Cambridge University Press, UK, 1990) p. 24.

E. Ness and N. Ryum, Scripta Metall. 5 (1971) 987.

R. J. Rioja and E. A. Ludwiczak, in “Aluminium-Lithium Alloys III”, edited by C. Baker, C. J. Peel, S. Harris and B. Noble (Institute of Metals, London, 1985).

J. M. Galbraith, M. H. Tosten and P. R. Howell, J. Mater. Sci. 22 (1987) p. 27.

S. Suresh, A. K. Vasudevan, M. H. Tosten and P. R. Howell, Acta Metall. 35 (1987) 25.

J. M. Silcock, J. Instit. Metals 88 (1959–60) 957.

B. Noble and G. E. Thompson, Metal Sci. J. 6 (1972) 167.

K. Schneider and M. Von Heimendhal, Z. Metallkde 64 (1977) 742.

T. S. Srivatsan, E. J. Coyne Jr and E. A. Starke Jr, J. Mater. Sci. 21 (1986) 1557.

R. E. Crooks and E. A. Starke Jr, Metall. Trans. 15A (1984) 1367.

T. S. Srivatsan and T. A. Place, J. Mater. Sci. 24 (1989) 1543.

C. E. Cross, D. L. Olson, G. R. Edwards and J. F. Capes, in “Aluminium-Lithium Alloys-II”, Proceedings of Second International Conference, edited by T. H. Sanders Jr and E. A. Starke Jr (Metallurgical Society, Warrendale, PA, 1985) p. 675.

J. A. Vaccari, Amer. Machinist February (1991) 50.

W. X. Feng, F. S. Lin and E. A. Starke Jr, Metall. Trans. 15A (1984) 1209.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ravindra, A., Dwarakadasa, E.S., Srivatsan, T.S. et al. Electron-beam weld microstructures and properties of aluminium-lithium alloy 8090. JOURNAL OF MATERIALS SCIENCE 28, 3173–3182 (1993). https://doi.org/10.1007/BF00354233

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00354233