Abstract

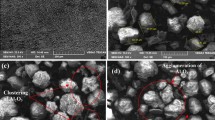

This paper aims to study the efficacy of (TiC+Fe3C+Fe2Ti+Fe) powder mixture produced by a new synthesis technique utilizing a cheap source of Fe–Ti and C (in terms of wear resistance and hardness). The powder product was used as reinforcement in Al matrix. Composites were produced by mixing 20 wt% of the reinforcing powder and 80 wt% of Al followed by 10 ton cold pressing and sintering for 2 h at 500 °C. The composites reinforced with the synthesized powders were compared with the composites produced using pure TiC as reinforcement material. Wear rate and hardness of composites using synthesized TiC mixture as the reinforcement material were found to be very close to that produced with pure TiC. The results of wear and hardness thus confirm that the synthesized powders containing TiC, Fe3C, Fe2Ti, and Fe can replace pure TiC in aluminum matrix composite applications.

Similar content being viewed by others

References

Lee D.W., Kim B.K.: Synthesis of nano-structured titanium carbide by Mg-thermal reduction. Scripta Metallurgica Materialia 48, 1513–1518 (2003)

Tong L., Reddy R.G.: Synthesis of titanium carbide nano-powders by thermal plasma. Scripta Metallurgica Materialia 52, 1253–1258 (2005)

Hsu S., Meyers M.A., Berkowitz A.: Synthesis of nanocrystalline titanium carbide by spark erosion. Scripta Metallurgica Materialia 32, 805–808 (1995)

Kumar S., Singh R., Singh T.P., Sethi B.L.: Review surface modification by electrical discharge machining: a review. J. Mater. Process. Technol. 209, 3675–3687 (2009)

Ye L.L., Quan M.X.: Synthesis of nanocrystalline TiC powders by mechanical alloying. Nanostruct. Mater. 5, 25–31 (1995)

Ali M., Basu P.: Mechanochemical synthesis of nanostructured titanium carbide from industrial Fe–Ti. J. Alloys Compd. 491, 581–583 (2010)

Kennedy A.R., Wyatt S.M.: Characterising particle–matrix interfacial bonding in particulate Al–TiC MMCs produced by different methods. Compos. Part A 32, 555–559 (2001)

Albitera A., Contrerasa A., Bedollab E., Pereza R.: Structural and chemical characterization of precipitates in Al-2024/TiC composites. Compos. Part A 34, 17–24 (2003)

Karantzalis A.E., Lekatou A.E., Poulas G.V., Mavros H.: Microstructural observations in a cast Al-Si-Cu/TiC composite. J. Mater. Eng. Perform. 19, 585–590 (2009)

Nukami T.: The growth of TiC particles in an Al matrix. J. Mater. Sci. Lett. 17, 267–269 (1998)

Ramesh K.C., Sagar R.: Fabrication of metal matrix composite automotive parts. India Int. J. Adv. Manuf. Technol. 15, 114–118 (1999)

Terry B.S., Chinyamakobvu O.S.: In situ production of Fe-TiC composites by reactions in liquid iron alloys. J. Mater. Sci. Lett. 10, 628–629 (1991)

Sen S., Stefanescu D.M., Dhindaw B.K.: Melt-processed Ni3Al matrix composites reinforced with TiC particles. Metall. Mater. Trans A 25, 2525–2534 (1994)

Yasmin T., Khalid A.A., Haque M.M.: Tribological (wear) properties of aluminum–silicon eutectic base alloy under dry sliding condition. J. Mater. Process. Technol. 154, 833–838 (2004)

Alman D.E., Hawk J.A.: Abrasive wear behavior of a brittle matrix (MoSi2) composite reinforced with a ductile phase (Nb). Wear 251, 890–900 (2001)

Niu, H.J.; Hampshire, D.P.: Fabrication of nanocrystalline and amorphous Chevrel phase PbMo6S8 powder by ball milling. Physica C 372–376, 1145–1147 (2002)

Panagopoulos C.N., Georgarakis K.G., Anagnostopoulou A.: The influence of grain size on the sliding wear behaviour of zinc. Mater. Lett. 60, 133–136 (2006)

Lee J.W., Munir Z.A., Ohyanagi M.: Dense nanocrystalline TiB2–TiC composites formed by field activation from high-energy ball milled reactants. Mater. Sci. Eng. A 325, 221–227 (2002)

Zhang S., Bui X.L., Jiang J., Li X.: Microstructure and tribological properties of magnetron sputtered nc-TiC/a-C nanocomposite. Surf. Coat. Technol, 198, 206–211 (2005)

Wereszczak A.A., Lin H.T., Gilde G.A.: The effect of grain growth on hardness in hot-pressed silicon carbides. J. Mater. Sci. 41, 4996–5000 (2006)

Zgalat-Lozinskii O.B., Bulanov V.N., Timofeeva I.I., Ragulya A.V., Skorokhod V.V.: Sintering of refractory compounds nanocrystalline powders. ii. Non-isothermal sintering of titanium nitride powder. Powder Metall. Metal. Ceram. 40, 11–12 (2001)

Nath A.K., Jiten C., Singh K.C.: Influence of ballmilling parameters on the particle size of bariumtitanate nanocrystalline powders. Physica B. 405, 430–434 (2010)

Meric C., Atik E., Kacar H.: Effect of aging on abrasive wear of deformable aluminum alloy AA6351. Metal Sci. Heat Treat. 46, 3–4 (2004)

Farid A., Guo S., Yang X., Lian Y.: Stainless steel binder for the development of novel Tic-reinforced steel cermets. J. Univ. Sci. Technol. Beijing. 13, 546–550 (2006)

Yang Q., Senda T., Ohmori A.: Effect of carbide grain size on microstructure and sliding wearbehavior of HVOF-sprayed WC–12% Co coatings. Wear 254, 23–34 (2003)

Albiter A., Contreras A., Bedolla E., Perez R.: Structural and chemical characterization of precipitates in Al-2024/TiC composites. Compos. Part A. 34, 17–24 (2003)

Kenned A.R.: Characterising particle–matrix interfacial bonding in particulate Al–TiC MMCs produced by different methods. Compos Part A. 32, 555–559 (2001)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ali, M., Basu, P., Liwa, M. et al. Comparison Between the Properties of Al–TiC and Al–(TiC+Fe3C+Fe2Ti+Fe) Composites. Arab J Sci Eng 38, 2785–2791 (2013). https://doi.org/10.1007/s13369-012-0480-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-012-0480-2