Abstract

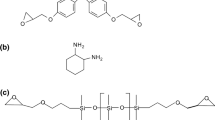

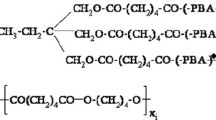

Dendritic polymers have attracted increasing attention in the field of epoxy resin toughening. This paper is the first report of the use of a novel dendritic polysiloxane (DPSO) bearing high epoxide groups to modify the diglycidyl ether of bisphenol-A (DGEBA). The thermal properties, toughness and morphology of the cured epoxy resins were examined by DSC, TGA, impact testing and SEM. The chemical structure of DPSO was confirmed by FTIR, 29Si NMR and GPC. The T g increased by approximately 7 °C after introducing the DPSO. The TGA results under N2 and air atmospheres showed that the initial degradation temperature for 5% weight loss (T d 5%), temperature for 50% weight loss (T d 50%) and residual weight percent at 800 °C (R 800) all increased after introducing DPSO. Moreover, the addition of 3 phr DPSO100 resulted in a 70.4% increase in impact strength compared to that of the neat epoxy. The morphology of the fracture surfaces shows that the miscibility of polysiloxane with epoxy resin increased with increasing number of epoxy groups in DPSO, and the improved toughness was attributed to the rubber-bridged effect. The high number of epoxy groups in dendritic polysiloxane can react during the curing process, and participate chemically in the crosslinking network. DPSO is expected to improve significantly the toughness and thermal stability of epoxy resin.

Similar content being viewed by others

References

G. Beaucage, S. Sukumaran, S. J. Clarson, M. S. Kent, and D. W. Schaefer, Macromolecules, 29, 8349 (1996).

M. Gonzalez, P. Kadlec, P. Štěpánek, A. Strachota, and L. Matejka, Polymer, 45, 5533 (2004).

P. G. Liu, J. X. Song, L. H. He, X. Q. Liang, H. Y. Ding, and Q. F. Li, Eur. Polym. J., 44, 940 (2008).

M. Alagar, A. A. Kumar, A. A. Prabu, and A. Rajendran, Int. J. Polym. Mater., 53, 45 (2004).

A. A. Prabu and M. Alagar, J. Macromol. Sci. Pure, 42, 175 (2005).

S. T. Lin and S. K. Huang, J. Polym. Sci. Part A: Polym. Chem., 34, 1907 (1996).

J. Y. Shieh, T. H. Ho, and C. S. Wang, Angew. Makromol. Chem., 224, 21 (1995).

S. S. Lee and S. C. Kim, J. Appl. Polym. Sci., 64, 941 (1997).

M. Gonzalez, P. Kadlec, P. Štěpánek, A. Strachota, and L. Matějka, Polymer, 45, 5533 (2004).

M. Jang and J. V. Crivello, J. Polym. Sci. Part A: Polym. Chem., 41, 3056 (2003).

S. S. Hou, Y. P. Chung, C. K. Chan, and P. L. Kuo, Polymer, 41, 3263 (2000).

Y. Morita, J. Appl. Polym. Sci., 97, 946 (2005).

M. Ochi, K. Takemiya, O. Kiyohara, and T. Nakanishi, Polymer, 41, 195 (2000).

W. C. Shih, C. C. M. Ma, J. C. Yang, and H. D. Chen, J. Appl. Polym. Sci., 73, 2739 (1999).

K. U. Chun-Kang and L. E. E. Yu-Der, Polymer, 48, 3 (2007).

L. Könczöl, W. Döll, U. Buchholz, and R. Mülhaupt, J. Appl. Polym. Sci., 54, 815 (1994).

Q. P. Guo, F. Chen, K. Wang, and L. Chen, J. Polym. Sci. Part B: Polym. Phys., 44, 3042 (2006).

W. Gong, K. Zeng, L. Wang, and S. X. Zheng, Polymer, 49, 3318 (2008).

S. T. Lin and S. K. Huang, J. Polym. Sci. Part A: Polym. Chem., 34, 1907 (1996).

L. Boogh, B. Pettersson, and J.-A. E. Månson, Polymer, 40, 2249 (1999).

R. J. Varley, Polym. Int., 53, 78 (2004).

R. J. Varley and W. Tian, Polym. Int., 53, 69 (2004).

S. H. Lee, W. S. Jahng, K. H. Park, N. Kim, W. J. Joo, and D. H. Choi, Macromol. Res., 11, 431 (2003).

B. G. Kim, J. K. Moon, E. H. Sohn, J. C. Lee, and J. K. Yeo, Macromol. Res., 16, 36 (2008).

D. P. Dworak and M. D. Soucek, Macromolecules, 37, 9402 (2004).

M. H. Hou, W. Q. Liu, Q. Q. Su, and Y. F. Liu, Polym. J., 39, 696 (2007).

S.-S. Hou, Y.-P. Chung, C.-K. Chan, and P.-L. Kuo, Polymer, 41, 3263 (2000).

S. Ahmad, S. M. Ashraf, E. Sharmin, A. Mohomad, and M. Alam, J. Appl. Polym. Sci., 100, 4981 (2006).

Z. K. Chen, G. Yang, J. P. Yang, S. Y. Fu, L. Ye, and Y. G. Huang, Polymer, 50, 1316 (2009).

J. M. Barton, J. Macromol. Sci.-Chem. A, 8, 25 (1974).

S. Kunz-Douglass, P. W. R. Beaumont, and M. F. Ashby, J. Mater. Sci., 15, 1109 (1980).

M. Zhang, http://writing.syr.edu/~cslipson/419619/LiteratureReviewrevised.pdf (2003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, S., Liu, W., Hu, C. et al. Toughening of epoxy resin system using a novel dendritic polysiloxane. Macromol. Res. 18, 392–398 (2010). https://doi.org/10.1007/s13233-010-0408-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-010-0408-1