Abstract

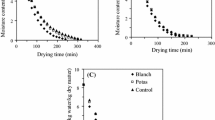

Modelling studies of guava drying and quality are presented using theoretical and statistical models by varying temperature from 55 to 75 °C and slice thickness from 3 to 9 mm. The quality of dried fruit was measured for its water activity, colour, vitamin C, and texture. The superposition technique with Midilli-Kucuk model showed efficiency in modelling the drying process with R 2 = 0.9991. The second-order polynomial equations adequately described the quality of dried guava with regression coefficient, R 2 > 0.7. Drying time was a good function of temperature and thickness (P < 0.001); water activity, colour and vitamin C showed strong dependence on temperature (P < 0.1); while texture was mainly influenced by its thickness (P < 0.005). The optimum drying temperature of 70 °C at slice thickness of 6 mm was determined using the desirability function method. Simultaneous modelling using the theoretical and statistical drying models provides information on water diffusion and evaporation with the drying responses and factors.

Similar content being viewed by others

References

Achanta S, Okos MR (1996) Predicting the quality of dehydrated foods and biopolymers- research needs and opportunities. Drying Technol 14:1329–1368

Akpinar EK, Bicer Y (2006) Mathematical modeling and experimental study on thin layer drying of strawberry. Int J Food Eng 2(1):1–16

AOAC (1990) Official Method of Analysis. No. 931.04. Association of Official Analytical Chemists, Washington, DC

Bakshi AS, Singh RP (1980) Drying characteristics of parboiled rice. In: Mujumdar AS (ed) Drying’80. Hemisphere Publishing Company, Washington DC

Beauchat LR (1981) Microbial stability as affected by water activity. Cereal Food World 25(7):345–349

Bourne M (2002) Food texture and viscosity-concept and measurement, 2nd edn. Academic, UK

Boyer RF (1986) Modern experimental biochemistry. The Benjamin/Cummings Publishing Company, Inc., Menlo Park

Chin NL, Chan SM, Yusof YA, Chuah TG, Talib RA (2009) Modelling of rheological behaviour of pummelo juice concentrates. J Food Eng 93:134–140

Chong CH, Law CL, Cloke M, Abdullah LC, Wan Daud WR (2009) Drying models and quality analysis of sun-dried ciku. Drying Technol 27:985–992

Chong CH, Law CL, Cloke M, Hii CL, Abdullah LC, Wan Daud WR (2008a) Drying kinetics and product quality of dried chempedak. J Food Eng 88:522–527

Chong CH, Law CL, Cloke M, Luqman CA, Wan Daud WR (2008b) Drying kinetics, texture, colour, and determination of effective diffusivities during sun drying of chempedak. Drying Technol 26:1286–1293

Crank J (1975) Mathematics of diffusion, 2nd edn. Oxford University Press, London

DeLong D (1992) How to dry food. The Berkley Publishing Group, New York

Derossi A, Severini C, Cassi D (2011) Mass transfer mechanisms during dehydration of vegetable food: traditional and innovative approaches. In: El-Amin M (ed) Advanced topics in mass transfer. InTech, Croatia

Doymaz I (2009) An experimental study on drying of green apples. Drying Technol 27:478–485

Erbay Z, Icier F (2009) A review of thin layer drying of foods: theory, modeling, and experimental results. Crit Rev Food Sci Nutr 50:441–464

Falade KO, Solademi OJ (2010) Modelling of air drying of fresh and blanched sweet potato slices. Int J Food Sci Technol 45:278–288

Fellows P (1988) Food processing technology. Ellis Horwood Ltd. & VCH, Chichester

Geankoplis CJ (2003) Transport processes and separation principles (include unit operation), 4th edn. Prentice Hall PTR, Upper Saddle River

Granato D, Bigaski J, Castro IA, Masson MI (2010) Sensory evaluation and physicochemical optimization of soy-based desserts using response surface methodology. Food Chem 121(3):899–906

Hawlader MNA, Perera CO, Tian M, Yeo KL (2006) Drying of guava and papaya: impact of different drying methods. Drying Technol 24:77–87

Huang Y, Whittaker AD, Lacey RE (2001) Automation for food engineering: food quality quantization and process control. CRC Press, Taylor & Francis Group, New York

Jangam SV, Mujumdar AS (2010) Basic concepts and definition. In: Jangam SV, Law CL, Mujumdar AS (eds) Drying of foods, vegetables and fruit, vol 1., pp 1–30

Janjai S, Precoppe M, Lamlert N, Mahayothee B, Bala BK, Nagle M, Muller J (2010) Thin-layer drying of litchi (Litchi chinensis Sonnn.). Food Bioprod Process 89:194–201

Kaya A, Aydin O, Kolayh S (2010) Effect of different drying conditions on the vitamin C (ascorbic acid) content of Hayward kiwifruits (Actinidia deliciosa Planch). Food Bioprod Process 88:165–173

Khazaei J, Arabhosseini A, Khosrobeygi Z (2008a) Application of superposition technique for modeling drying behaviour of Avishan (Zataria multiflora) leaves. Trans ASABE 51(4):1383–1393

Khazaei J, Chegini G-R, Bakhshiani M (2008b) A novel alternative method for modeling the effects of air temperature and slice thickness on quality and drying kinetics of tomato slices: superposition technique. Drying Technol 36:759–775

Lee JH, Kim HJ (2009) Vacuum drying kinetics of Asian white radish (Raphanus sativus L.) slices. LWT—Food Sci Technol 42:180–186

Marinos-Kouris D, Maroulis ZB (1995) Transport properties in the drying of solids. In: Mujumdar AS (ed) Handbook of industrial drying, 2nd edn. Marcel Dekker, New York, pp 113–160

McLaughlin CP, Magee TRA (1998) The determination of sorption isotherm and the isosteric heats of sorption for potatoes. J Food Eng 35:267–280

Mittal GS (1999) Mass diffusivity of food products. Food Rev Int 15(1):19–66

Myers RH, Montgomery DC, Anderson-Cook CM (2009) Response surface methodology: process and product optimization using designed experiments, 3rd edn. John Wiley and Sons, Inc., New York

Nguyen M-H, Price WE (2007) Air-drying of banana: infuence of experimental parameters, slab thickness, banana maturity and harvesting season. J Food Eng 79:200–207

Ong SP, Law CL (2009) Mathematical modeling of thin layer drying of salak. J Appl Sci 9(17):3048–3054

Panchariya PC, Popovic D, Sharma AL (2002) Thin-layer modelling of black tea drying process. J Food Eng 52:349–357

Patkai G (2006) Fruit as an ingredient in a fruit product. In: Hui YH (ed) Handbook of fruits and fruit processing, 1st edn. Blackwell Publishing, USA, pp 217–230

Perera CO (2005) Selected quality attributes of dried foods. Drying Technol 23:717–730

Pott I, Neidhart S, Muhlbauer W, Carle R (2005) Quality improvement of non-sulphited mango slices by drying at high temperatures. Innov Food Sci Emerg Technol 6:412–419

Rahman MS (2005) Dried food properties: challenges ahead. Drying Technol 23:695–715

Rizvi SSH (1986) Thermodynamic properties of food in dehydration. In: Rao MA, Rizvi SSH (eds) Engineering properties of foods. Marcel Dekker, New York, pp 190–193

Sacilik K, Elicin AK (2006) The thin layer drying characteristics of organic apple slices. J Food Eng 73:281–289

Sagar VR, Suresh KP (2010) Recent advances in drying and dehydration of fruits and vegetables: a review. J Food Sci Technol 47(1):15–26

Sirisomboon P, Tanaka M, Akinaga T, Kojima T (2000) Evaluation of the textural properties of Japanese pear. J Texture Stud 31:665–677

Steffe JF (1996) Rheological methods in food process engineering, 2nd edn. Freeman Press, MI

Walpole RE, Myers RH, Myers SL, Ye K (2002) Probability and statistics for engineers and scientists, 7th edn. Prentice Hall, NJ

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kek, S.P., Chin, N.L. & Yusof, Y.A. Simultaneous time-temperature-thickness superposition theoretical and statistical modelling of convective drying of guava. J Food Sci Technol 51, 3609–3622 (2014). https://doi.org/10.1007/s13197-013-0923-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-013-0923-0