Abstract

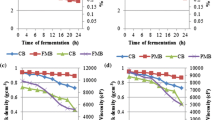

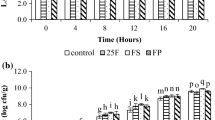

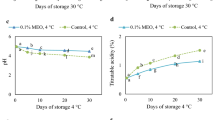

Idli is a traditional fermented rice and black gram based food. Idli batter is prepared by soaking polished parboiled rice and decorticated black gram for 4 h at 30 ± 1 °C in water. The soaked mass was ground using a grinder with adequate amount of water. The blend ratios of 2:1, 3:1 and 4:1 (w/w) batter were allowed for fermentation for different periods with the addition of 2% (w/w) of salt. The rheology of the product was assessed using a Brookfield Viscometer having disc spindles. Shear stress values were in the range of 0.22 and 4 Pa and reached a maximum value at 7 h of fermentation. The density, pH, and percentage total acidity of batter during fermentation for different blend ratios ranged between 0.93 and 0.59 gm cm−3, 4.21 and 5.9 and 0.44 and 0.91% respectively. During fermentation, maximum production of riboflavin and thiamine were found to be 0.76 mg/100 gm and 0.73 mg/100 gm in 3:1 blend ratio of idli batter; and the folic acid content was found to be at a maximum of 0.75 mg/100 gm of idli batter after 10 h of fermentation. Digestibility in terms of amino N2 content was analysed by formol titration.

Similar content being viewed by others

References

Aykroyd WR (1963) Special Report ICMR. No. 42. 6th edn. New Delhi

Balasubramanium S, Viswanathan R (2007) Properties of idli batter during its fermentation time. J Food Process Preserve 31:32–40

Balasubramanium S, Singh N, Ilys SM, Wanjari OD (2006) Effect of selected decorticated legumes protein on rheology of maize extrudate pastes. J Food Sci Technol 43:590–594

Chavan JK, Kadam SS, Beuchat LR (1989) Nutritional improvement of cereals by fermentation. Crit Rev Food Sci Nutr 28:349–400

Davidson S, Meiklejohn AP, Passmore R (1963) Human nutrition and dietetics, 2nd edn. Livingstone, Edinburgh

Desikachar HSR, Radhakrishnamurthy R, Rao GR, Kadol SB, Srinivasan M, Subramanyan V (1962) Studies on idli fermenteation. Part I. Some accompanying changes in the batter. J Sci Ind Res (India) 19C:168–172

Desikachar HSR, Raghavandra Rao SN, Ananthachar TK (1965) Effect of degree of milling on water absorption of rice during cooking. J Food Sci Technol 2:110112

Doughty J (1964) F.A.O. Nutr. Studies 19, Rome, Italy

Ghosh D, Chattopadhyay P (2010) Application of principal component analysis (PCA) as a sensory assessment tool for fermented food products. J Food Sci Technol JFST-D-09-00006

Holdsworth SD (1971) Applicability of rheological models to the interpretation of flow and processing behavior of fluid food products. J Tex Studies 2:393–418

Joseph E, Crites SG, Swanson BG (1993) Microstructure of idli. Food Struct 12:483–488

Kodicek E, Wang YL (1949) The fluorimetric estimation of riboflavin in foodstuffs and other biological material. Biochem J 44:340–343

Mitschka P (1982) Simple conversion of Brookfield R. V. T readings into viscosity functions. Rheol Acta 21:207–209

Mukherjee SK, Albury MN, Perderson CS, Van Veen AG, Stinekraus KH (1965) Role of Leuconostoc mesenteroides in leavening the batter of idli, a fermented food in India. Appl Microbiol 13:227–231

Nagarjuna VD, Manohar B (2000) Rheology and particle size changes during Idli fermentation. J Food Eng 43:167–171

Official Methods of Analysis of Official Analytical Chemists (A.O.A.C.) published by the A.O.A.C. (1970) Benjamin Franklin. 11th edn. Washington, DC 20044

Rajalakshmi R, Nanavaty K, Gumastha A (1964) Chemical and biological evaluation of the effects of fermentation on the nutritive value of foods prepared from rice and grams. J Nutr Diet India 1:276

Ramakrishnan CV (1979) Terminal report of American PL 480-project Nr GF-IN-491. Study of Indian fermented foods from legumes and production of similar fermented foods from U.S. soybean. Biochemistry Dept. Baroda University, Baroda

Soni SK, Sadhu DK (1990) Indian fermented foods: microbiological and biochemical aspects. Indian J Microbiol 30:135–157

Steinkraus KH (1983) Handbook of indigenous fermented foods. Marcel Dekker, New York, pp 132–146

Steinkraus KH (1996) Handbook of Indigenous fermented foods, 2nd edn. Marcel Dekker Inc, New York, 331, 776

Steinkraus KH, Van Veen AG, Thiebeau DB (1967) Studies on idli- an Indian fermented black-gram rice food. Food Technol 21:916–919

Thyagaraja N, Otani H, Hosono A (1991) Microflora in idli, a traditional fermented cereal pulse product from India. Lebensm Wiss Technol 24:916–919

Vogel AI, Tatchell AR, Furnis BS, Hannaford AJ, Smith PWG (1990) Vogel’s textbook of practical organic chemistry. Determination of amino acids by formol titration, 5th edn. The English Language Book Society, London

Acknowledgement

The authors gratefully acknowledge the University Grants Commission, New Delhi, India for providing financial assistance to carry out the research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghosh, D., Chattopadhyay, P. Preparation of idli batter, its properties and nutritional improvement during fermentation. J Food Sci Technol 48, 610–615 (2011). https://doi.org/10.1007/s13197-010-0148-4

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-010-0148-4