Abstract

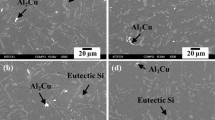

The austenite nucleation and growth morphology was investigated through experiments by inoculation with pure Al in a controlled environment using DTA furnace and H.F furnace. The austenite volume fraction and the dendrite growth orientations were affected by the addition of Al to the melt. Thermal analyses were performed to study the effect of sulfur content on austenite volume fraction and growth morphology using DSC. The possibility of austenite nucleation by MnS particles was analyzed. Different sulfur contents in the alloys were resulting in change in the latent heat of solidification and the rate of austenite formation. Austenite volume fraction was measured with four methods, colour etching, DSC thermal analysis, lever rule, and using LH calculated by Thermo-Calc data base, and a comparison was made among them.

Similar content being viewed by others

References

Muhmond H M, and Fredriksson H, Metall Mater Trans B (2012). doi:10.1007/s11663-012-9768-6.

Carlberg T, and Fredriksson H, Solidification and casting of metals, in Proc Int Conf Solidification (1977), Metals Soc., London, (1979) p 115.

Ruff G F, and Wallace J F, Trans AFS 84 (1976) 705.

Lux B, and Kurz W, Solidification of Metals, Brighton (1967), ISI Publication (1968).

Kayama N, Nashimoto K, and Suzuki K, ‘Effect of SiO2 on Primary Austenite Nucleation in Hypo Eutectic Cast Iron’, Report from the Casting Laboratory, no. 35, Waseda University, Japan (1984).

Diószegi A, Liu K Z, and Svensson I L, Int J Cast met Res 20 (2007) 68.

Elmquist L, Salera S and Diószegi A, Int J Cast met Res 23 (2010) 124.

Mizogushi T, and Perepezko J H, Mater Sci Eng A A226–A228 (1997) 813.

Fredriksson H, Stjerndahl J, and Tinoco J, Mater Sci Eng A 413–414 (2005) 363.

Fredriksson H, Adv Mater Res 4 (1997) 505–512.

Elbenawy T, and Fredriksson H, Adv Mater Trans JIM 41 (2000) 507–515.

Mahmoudi J, and Fredriksson H, Mater Sci Eng A 22 (1997) 226–228.

Tinoco J, and Fredriksson H, Proceedings of the International Conference on the Science of Casting and Solidification, Brasov, Romania, May (2001), p 305–311.

Tinoco J, Delvasto P, Quintero O, and Fredriksson H, Proceedings of the international Conference on Solidification and Processing of Cast Iron VII, Barcelona, Spain, September (2002).

Brandes E A, and Brook G B, Smithells Metals Reference Book, ed. 7, (1992), ch. 6.

Fredriksson H, and Åkerlind U, Materials Processing during Casting, J. Wiley, England, (2006) p 171, ISBN: 9-78-0-470-01514-8.

Lux B, AFS Cast Met Res J 3 (1972) p 25–38.

Angus H T, Cast Iron: Physical and Engineering Properties, Butterworth and Co Ltd, England (1976) p 112, ISBN. 0-408-70688-0.

Acknowledgments

The authors would like to acknowledge the support provided by ELKEM-Norway for this research project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Muhmond, H.M., Fredriksson, H. An Investigation on the Effect of S and Al on the Austenite Growth Morphology in Gray Cast Iron, Using Thermal Analysis and Etching Technique. Trans Indian Inst Met 66, 185–192 (2013). https://doi.org/10.1007/s12666-013-0241-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-013-0241-2