Abstract

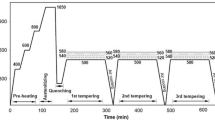

The microstructure and the stability of carbides after heat treatments in an H23 tool steel were investigated. The heat treatments consisted of austenization at two different austenizing temperatures (1100°C and 1250°C), followed by water quenching and double-aging at 650°C, 750°C, and 800°C with air cooling between the first and second aging treatments. Martensite did not form in the as-quenched microstructures, which consisted of a ferrite matrix, M6C, M7C3, and MC carbides. The double-aged microstructures consisted of a ferrite matrix and MC, M6C, M7C3, and M23C6 carbides. Secondary hardening as a consequence of secondary precipitation of fine M2C carbides did not occur. There was disagreement between the experimental microstructure and the results of thermodynamic calculations. The highest double-aged hardness of the H23 tool steel was 448 HV after austenization at 1250°C and double-aging at 650°C, which suggested that this tool steel should be used at temperatures below 650°C.

Similar content being viewed by others

References

G.A. Roberts, G. Kraus, and R.L. Kennedy, Tool Steels, Materials Park, ASM International, Ohio, 1998.

M.L. Fares, M. Athmani, Y. Khelfaoui, and A. Khettache, An investigation into the effects of conventional heat treatments on mechanical characteristics of new hot working tool steel, IOP Conf. Ser. Mater. Sci. Eng., 28(2012), No. 1, art. No. 012024.

P. Bała and J. Krawczyk, Transformation during quenching and ageing of hot-work tool steel, Hradec Moravici, 19(2009), p. 1.

Z. Zhang, D. Delagnes, and G. Bernhart, Microstructure evolution of hot-work tool steels during tempering and definition of a kinetic law based on hardness measurements, Mater. Sci. Eng. A, 380(2004), p. 222.

A. Medvedeva, J. Bergström, S. Gunnarsson, and J. Andersson, High temperature properties and microstructural stability of hot work tool steels, Mater. Sci. Eng. A, 523(2009), No. 1–2, p. 39.

M. Nurbanasari, P. Tsakiropoulos, and E.J. Palmiere, A study of carbide precipitation in a H21 tool steel, ISIJ Int., 54(2014), No. 7, p. 1667.

R.C. Thomson and H.K.D.H. Bhadeshia, Carbide precipitation in 12Cr1MoV power plant steel, Metall. Trans. A, 23(1992), p. 1171.

N. Dudova and R. Kaibyshev, On the precipitation sequence in a 10% Cr steel under tempering, ISIJ Int., 51(2011), No. 5, p. 826.

M.A. Asadabad, S. Kheirandish, and A.J. Novinrooz, Tempering behavior of 4.5Cr-2W-0.25V steel, J. Iron Steel Res. Int., 17(2010), No. 10, p. 57.

M. Nurbanasari, P. Tsakiropoulos, and E.J. Palmiere, On the solidification of a H23 tool steel, Trans. Indian Inst. Met., 67(2014), No. 6, p. 935.

N. Mebarki, D. Delagnes, P. Lamesle, F. Delmas, and C. Levaillant, Relationship between microstructure and mechanical properties of a 5% Cr tempered martensitic tool steel, Mater. Sci. Eng. A, 387–389(2004), p. 171.

A.M. Elrakayby and B. Mills, Identification of carbides in high-speed steels, J. Mater. Sci. Lett., 5(1986), p. 332.

F. Abe, H. Araki, and T. Noda, The effect of tungsten on dislocation recovery and precipitation behavior of low-activation martensitic 9Cr steels, Metall. Trans. A, 22(1991), p. 2225.

F.B. Pickering, The properties of tool steels for mould and die applications [in] G. Krauss and H. Nordberg, eds., Tool Materials for Molds and Dies: Application and Performance, CSM Press Golden, Colorado, 1987, p. 3.

D.J. Dyson and K.W. Andrews, Carbide M7C3 and its formation in alloy steels, J. Iron Steel Inst., 207(1969), No.2, p.208.

K. Kuo, Carbides in chromium, molybdenum, and tungsten steels, J. Iron Steel Inst., 173(1953), p. 363.

R. Wilson, Metallurgy and Heat Treatment of Tool Steel, Mc Graw-Hill, London, 1975.

G.E. Totten, L. Xie, and K. Funatani, Handbook of Mechanical Alloy Design, Marcel Dekker Inc, New York, 2004.

S. Karagoz and H. Fischmeister, Microstructure and toughness in high speed tool steels: the influence of hot reduction and austenitization temperature, Steel Res., 58(1987), No. 8, p. 353.

A. Saha Podder and H.K.D.H. Bhadeshia, Thermal stability of austenite retained in bainitic steels, Mater. Sci. Eng. A, 527(2010), No. 7–8, p. 2121.

G.J. Cai, H.O. Andren, and L.E. Svensson, Microstructural change of a 5% Cr steel weld metal during tempering, Mater. Sci. Eng. A, 242(1998), No. 1–2, p. 202.

R.G. Baker and J. Nutting, The tempering of 2.25Cr%-1%Mo steel after quenching and normalizing, J. Iron Steel Inst., 202(1959), p. 257.

H.K.D.H. Bhadeshia and R.W.K. Honeycombe, Steels: Microstructure and Properties, Elsevier Ltd., Oxford, 2006.

A. Bjärbo and M. Hättestrand, Complex carbide growth, dissolution and coarsening in a modified 12 pct chromium steel-an experimental and theoretical study, Metall. Mater. Trans. A, 32(2001), No. 1, p. 19.

K. Asakura, A. Kohyama, and T. Yamada, Mechanical properties and microstructure changes of low-activation 3Cr-2W-V-Ti ferritic steels developed for nuclear applications, ISIJ Int., 30(1990), No. 11, p. 947.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nurbanasari, M., Tsakiropoulos, P. & Palmiere, E.J. Microstructural evolution of a heat-treated H23 tool steel. Int J Miner Metall Mater 22, 272–284 (2015). https://doi.org/10.1007/s12613-015-1071-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-015-1071-5