Abstract

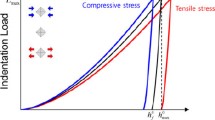

Surface residual stress is usually characterized by two parameters; (1) magnitude and (2) direction of two principal residual stresses. We propose a novel way to evaluate these parameters by instrumented indentation testing (IIT) using a Knoop indenter, which has two-fold symmetry. Non-equibiaxial surface stress causes a shift from residual stress in the force-indentation depth curve of IIT that depends on the Knoop indentation in-plane angle between residual stress and long diagonal of Knoop indenter. We develop a theoretical model to evaluate surface residual stress using only experimental parameters obtained by four Knoop IITs at 45° rotated angles, by introducing mathematical definition of conversion factor, a, which ratio of normal and parallel conversion factors was known as constants (~0.34) on previous studies. We verify this model by Knoop IITs on four metallic cruciform samples in which the surface residual stress is controlled by bending. Experimental results of principal stress and direction show good agreements with applied stress and directions.

Similar content being viewed by others

References

Y.-H. Lee and D. Kwon, Acta Mater. 52, 1555 (2004).

J.-I. Jang, J. Ceram. Process. Res. 10, 391 (2009).

Y.-H. Lee, J. S. Park, Y.-i. Kim, and Y.-H. Huh, Korean J. Met. Mater. 53, 90 (2015).

G. Sines and R. Carlson, ASTM Bulletin 180, February, 35 (1952).

A. Bolshakov, W. C. Oliver, and G. M. Pharr, J. Mater. Res. 11, 760 (1996).

T. Y. Tsui, W. C. Oliver, and G. M. Pharr, J. Mater. Res. 11, 752 (1996).

Y.-H. Lee and D. Kwon, J. Mater. Res. 17, 901 (2002).

S. K. Kang, J. Y. Kim, C. P. Park, H. U. Kim, and D. Kwon, J. Mater. Res. 25, 337 (2010).

J. Frankel, A. Abbate, and W. Scholz, Exp. Mech. 33, 164 (1993).

W. R. Lafontaine, C. A. Paszkiet, M. A. Korhonen, and C.-Y. Li, J. Mater. Res. 6, 2084 (1991).

A. V. Zagrebelny and C. B. Carter, Scripta Mater. 37, 1869 (1997).

S. Suresh and A. E. Giannakopoulos, Acta Mater. 46, 5755 (1998).

J. H. Han, J.-S. Lee, M.-J. Choi, G. Lee, K.-H. Kim, and D. Kwon, Key Engineering. 345-346, 1125 (2007).

M.-J. Choi, S.-K. Kang, I. Kang, and D. Kwon, J. Mater. Res. 27, 1 (2011).

Y.-C. Kim, M.-J. Choi, D. Kwon, and J.-Y. Kim, Met. Mater. Int. 21, 850 (2015).

E. K. Girija, G. R. Sivakumar, S. Narayana Kalkura, P. Ramasamy, D. R. Joshi, and P. B. Sivaraman, Mat. Chem. Phys. 63, 50 (2000).

D. Tabor, The Hardness of Metals, pp. 105–106, Oxford, New York (1951).

Y.-H. Lee, Y. Kim, Y.-C. Kim, J.-Y. Kim, and J.-I. Jang, Met. Mater. Int. 20, 439 (2014).

STM E8 / E8M-15a, Standard Test Methods for Tension Testing of Metallic Materials, ASTM International, PA (2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, YC., Ahn, HJ., Kwon, D. et al. Modeling and experimental verification for non-equibiaxial residual stress evaluated by Knoop indentations. Met. Mater. Int. 22, 12–19 (2016). https://doi.org/10.1007/s12540-015-5515-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-015-5515-2