Abstract

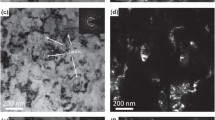

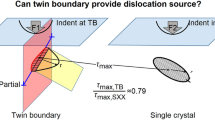

Deformation twinning in nanocrystalline and ultrafine-grained materials has attracted much attention in recent years due to the ability of a high density of twin boundaries to dramatically improve mechanical properties such as yield strength and ductility. Various processing conditions such as ball milling, cryomilling, electrodeposition, and equi-channel angular extrusion have been used to form deformation twins in metals. Most techniques for estimating the shear stress needed to form deformation twins are based indirectly on the processing conditions. Here, a new method to directly measure the shear stress needed to form twin boundaries through in-situ transmission electron microscopy nanocompression testing will be described.

Similar content being viewed by others

References

L. Lu et al., Science, 304 (2004), pp. 422–426.

X.H. Chen and L. Lu, Scripta Materilia, 57 (2007), pp. 133–136.

C.X. Huang et al., Acta Materialia, 54 (2006), pp. 655–665.

M. Chen et al., Science, 300 (2003), pp. 1275–1277.

H. Rosner, J. Markmann, and J. Weismuller, Philosophical Magazine Letters, 84 (2004), pp. 321–334.

X.L. Wu and Y.T. Zhu, Applied Physics Letters, 89 (2006), no. 031922.

T.H. Blewitt, R.R. Coltman, and J.K. Redman, Journal of Applied Physics, 28 (1957), pp. 651–660.

H. Suzuki and C.S. Barrertt, Acta Metallurgica, 6 (1958), pp. 156–165.

V. Yamakov et al., Nature Materials, 1 (2002), pp. 1–4.

J. Schiotz and K.W. Jacobsen, Science, 301 (2003), pp. 1357–1359.

S. Ogata, J. Li, and S. Yip, Physical Review B, 71 (2005), no. 224102.

N. Bernstein and E.B. Tadmor, Physical Review B, 69 (2004), no. 094116.

M.D. Uchic et al., Science, 305 (2004), pp. 986–989.

Z.W. Shan et al., Nature Materials, 7 (2007), pp. 115–119.

G.E. Dieter, Mechanical Metallurgy, 3rd edition (London: McGraw Hill, 1988).

M. Yu et al., Physical Review B, 74 (2006), p. no. 172107.

S. Kibey et al., Acta Materialia, 55 (2007), pp. 6843–6851.

Y.T. Zhu et al., Journal of Applied Physics, 98 (2005), no. 034319.

J.Y. Huang, Y.K. Wu, and H.Q. Ye, Acta Materialia, 44(3) (1996), pp. 1211–1221.

C.J. Youngdahl et al., Scripta Materialia, 44 (2001), pp. 1475–1478.

X.Z. Liao et al., Applied Physics Letters, 84 (2004), pp. 592–594.

H.V. Swygenhoven, P.M. Derlet, and A.G. Froseth, Nature Materials, 3 (2004), pp. 399–403.

M. Dao et al., Acta Materialia, 54 (2006), p. 5421.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sriram, V., Yang, JM., Ye, J. et al. Determining the stress required for deformation twinning in nanocrystalline and ultrafine-grained copper. JOM 60, 66–70 (2008). https://doi.org/10.1007/s11837-008-0121-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-008-0121-0