Abstract

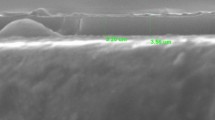

A high efficiency methane sulfonic acid electrolyte used for tin electrodeposition was studied, and the properties of the resulting deposits were compared to those of tin coatings obtained from an industrial phenol sulfonic acid electrolyte. Cyclic voltammetry was used to study the effect of organic additives on the reduction process to define the composition of the electrolytic bath. Thick tin electrodeposits were obtained on rotating cylinder steel electrodes, and their surface morphology, preferred crystal orientation, surface roughness, micro hardness, and tribological behavior were measured. Smooth, adherent, and bright tin coatings were obtained from the methane sulfonic acid electrolyte, which differed in morphology and texture from tin electrodeposited from the industrial bath. Influence of organic additives on preferred crystal orientation of the coatings was found to be stronger than changing the supporting sulfonic acid type. Tribological tests showed that the two types of deposits have a similar coefficient of friction. However, tin coatings obtained from methane sulfonic electrolytes presented a lower wear resistance and underwent galling at lower loads.

Similar content being viewed by others

References

R. Winand, Electrocrystallization—Theory and Applications, Hydrometallurgy, 1992, 29, p 567–598

M.E. Browning, Plating and Electroplating, Surface Engineering. ASM International, New York, 1994, p 239–242

M. Schlesinger and M. Paunovic, Modern Electroplating, 5th ed., Willey, New Jersey, 2010

T.P. Murphy and H. Smith, Changes in Tinplate Surfaces During DWI Can Manufacture, in 3rd International Tinplate Conference, Conference Date (London), 1984, p 299–309

D. Thomson, D.A. Luke, and C. Mosher, Reducing Tin Sludge in Acid Tin Plating, 1995, US 5,378,347

A. Survila, Z. Mockus, and R. Juškėnas, Current Oscillations Observed During Codeposition of Copper and Tin from Sulfate Solutions Containing Laprol 2402C, Electrochim. Acta, 1998, 43(8), p 909–917

G.I. Medvedev, N.A. Makrushin, and O.V. Ivanova, Electrodeposition of Copper-Tin Alloy from Sulfate Electrolyte, Russ. J. Appl. Chem., 2004, 77(7), p 1104–1107

E. Ilgar, Electrolytic Tin Plating Process with Reduced Sludge Production, 1998, US 5,814,202

E. Morgan, Tinplate Manufacture, Tinplate & Modern Canmaking Technology (Chap. 2), E. Morgan, Ed., Pergamon, Oxford, 1985, p 5–73

A. Sharma, S. Bhattacharya, R. Sen, B.S.B. Reddy, H.J. Fecht, K. Das, and S. Das, Influence of Current Density on Microstructure of Pulse Electrodeposited Tin Coatings, Mater. Charact., 2012, 68, p 22–32

U. Sahaym, S.L. Miller, and M.G. Norton, Effect of Plating Temperature on Sn Surface Morphology, Mater. Lett., 2010, 64(14), p 1547–1550

G.-S. Tzeng, Effects of Additive Agents on the Kinetics of Tin Electrodeposition from an Acidic Solution of Tin(II) Sulfate, Plat. Surf. Finish., 1995, 82, p 67–71

F. Bottos, B. Alavanjo, M. Steel, G. Federman, and J. Swanson, Commercial Production of Tinplate with an MSA Process on a Horizontal Cell Tinplate Line at National Steel’s Midwest Division, 6th International Tinplate Conference, Conference Date (London), 1996, p 38–59

G. Federman, An Improved High Speed MSA Tinplate Process: Laboratory Testing to Production Experience, 7th International Tinplate Conference, Conference Date (Amsterdam), 2000

C. Rosenstein, Methane Sulfonic Acid as an Electrolyte for Tin, Lead and Tin-Lead Plating for Electronics, Metal Finish., 1990, 88, p 17–21

Y.-H. Yau, The Effect of Process Variables on Electrotinning in a Methanesulfonic Acid Bath, J. Electrochem. Soc., 2000, 147(3), p 1071–1076

N.M. Martyak and R. Seefeldt, Additive-Effects During Plating in Acid Tin Methanesulfonate Electrolytes, Electrochim. Acta, 2004, 49, p 4303–4311

C.T.J. Low and F.C. Walsh, The Influence of a Perfluorinated Cationic Surfactant on the Electrodeposition of Tin from a Methanesulfonic Acid Bath, J. Electroanal. Chem., 2008, 615, p 91–102

W. Zhang, J. Guebey, and M. Toben, A novel Electrolyte for the high Speed Electrodeposition of Bright Pure Tin at Elevated Temperatures, Metal Finish., 2011, 109(1-2), p 13–19

F.I. Nobel, B.D. Ostrow, and D.N. Schram, Tin-Lead Electroplating Solutions, 1988, US 4,717,460

F.I. Nobel, B.D. Ostrow, and D.N. Schram, Bath and Process for Plating Tin, Lead and Tin-Lead Alloys, 1986, US 4,565,609

K. Obata, N. Dohi, Y. Okuhama, S. Masaki, Y. Okada, and M. Yoshimoto, Tin, Lead, and Tin-Lead Alloy Plating Baths, 1984, US 4,459,185

C. Xu, Y. Zhang, C. Fan, P. Chiu, and J.A. Abys, Surface morphology, appearance and tribology of electrodeposited tin films, Plat. Surf. Finish., 2000, 87(9), p 88–92

C. Xu, Y. Zhang, P. Chiu, and J.A. Abys, Glossiness, Morphology and Microstructure of Electrodeposited Sn Films, Surface Finishing, Conference Date, 1999

C.H. O’driscoll, Tin Plating Electrolyte Compositions, 2001, European Patent EP0857226 B1

C.T.J. Low, F.C. Walsh, and C. Ponce de Leon, The Rotating Cylinder Electrode (RCE) and its Applications to the Electrodeposition of Metals, Aust. J. Chem., 2005, 58, p 246–262

D.R. Gabe, G.D. Wilcox, J. Gonzalez-Garcia, and F.C. Walsh, The Rotating Cylinder Electrode: Its Continued Development and Application, J. Appl. Electrochem., 1998, 28(8), p 759–780

L.N. Bengoa, W.R. Tuckart, N. Zabala, G. Prieto, and W.A. Egli, Bronze Electrodeposition from an Acidic Non-cyanide High Efficiency Electrolyte: Tribological Behavior, Surf. Coat. Technol., 2014, 253, p 241–248

Y.-F. Tu, X.-H. Chao, J.-P. Sang, S.-Y. Huang, and X.-W. Zou, Thin-Layer Electrodeposition of Zn in the Agar Gel Medium, Phys. A, 2008, 387(16-17), p 4007–4014

L.P. Bérubé and G. L’Espérance, A Quantitative Method of Determining the Degree of Texture of Zinc Electrodeposits, J. Electrochem. Soc., 1989, 136(8), p 2314–2315

JCPDS-ICDD, Powder Diffraction Files Sn 04-0673, International Center for Diffraction Data, Newtown Square, 1997

S. Wen and J.A. Szpunar, Nucleation and Growth of Tin on Low Carbon Steel, Electrochim. Acta, 2005, 50(12), p 2393–2399

G. Gunawardena, G. Hills, and I. Montenegro, Electrochemical Nucleation: Part V. Electrodeposition of Cadmium Onto Vitreous Carbon and Tin Oxide Electrodes, J. Electroanal. Chem., 1985, 184(2), p 371–389

M. Moharana and A. Mallik, Nickel Electrocrystallization in Different Electrolytes: An In-Process and Post Synthesis Analysis, Electrochim. Acta, 2013, 98, p 1–10

J. Torrent-Burgués, E. Guaus, and F. Sanz, Initial Stages of Tin Electrodeposition from Sulfate Baths in the Presence of Gluconate, J. Appl. Electrochem., 2002, 32(2), p 225–230

E. Gómez, E. Guaus, F. Sanz, and E. Vallés, Tin Electrodeposition on Carbon Electrodes. From Nuclei to Microcrystallites, J. Electroanal. Chem., 1999, 465(1), p 63–71

K.I. Popov, N.V. Krstajić, and M.I. Čekerevac, The Mechanism of Formation of Coarse and Disperse Electrodeposits, Modern Aspects of Electrochemistry, R.E. White, B.E. Conway, and J.O.M. Bockris, Ed., Plenum, New York, 1996, p 261–312

K.I. Popov and N.D. Nikolic, General Theory of Disperse Metal Electrodeposits Formation, Electrochemical Production of Metal Powders, S.S. Djokić, Ed., Springer, New York, 2012, p 1–62

G.I. Medvedev, N.A. Makrushin, and A.N. Dubenkov, Organic Compounds for Preparing Lustrous Tin Coatings, Russ. J. Appl. Chem., 2002, 75(11), p 1799–1803

G.I. Medvedev and N.A. Makrushin, A Study of the Kinetics of Tin Electrodeposition from Sulfate Electrolyte with Organic Additives, Russ. J. Appl. Chem., 2002, 75(8), p 1234–1236

F.J. Barry and V.J. Cunnane, Synergistic Effects of Organic Additives on the Discharge, Nucleation and Growth Mechanisms of Tin at Polycrystalline Copper Electrodes, J. Electroanal. Chem., 2002, 537, p 151–163

R. Sekar, C. Eagammai, and S. Jayakrishnan, Effect of Additives on Electrodeposition of Tin and Its Structural and Corrosion Behaviour, J. Appl. Electrochem., 2010, 40(1), p 49–57

X. Guo, G. Zhang, W. Li, Y. Gao, H. Liao, and C. Coddet, Investigation of the Microstructure and Tribological Behavior of Cold-Sprayed Tin-Bronze-Based Composite Coatings, Appl. Surf. Sci., 2009, 255(6), p 3822–3828

X. Guo, G. Zhang, W. Li, L. Dembiski, Y. Gao, H. Liao, and C. Coddet, Microstructure, Microhardness and Dry Friction Behavior of Cold-Sprayed Tin Bronze Coatings, Appl. Surf. Sci., 2007, 254(5), p 1482–1488

K. Holmberg, A. Matthews, and H. Ronkainen, Coatings Tribology—Contact Mechanisms and Surface Design, Tribol. Int., 1998, 31(1-3), p 107–120

A. Kapoor, Wear by Plastic Ratchetting, Wear, 1997, 212, p 119–130

Acknowledgments

The authors would like to thank the Comisión de Investigaciones Científicas de la Provincia de Buenos Aires (CICPBA), Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET), Universidad Nacional de La Plata (UNLP) and Universidad Nacional del Sur (UNS) for the financial support provided. This research was partially financed by SIDERCA S.A.I.C. (Tenaris) through a collaboration agreement with CONICET.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bengoa, L.N., Tuckart, W.R., Zabala, N. et al. Tin Coatings Electrodeposited from Sulfonic Acid-Based Electrolytes: Tribological Behavior. J. of Materi Eng and Perform 24, 2274–2281 (2015). https://doi.org/10.1007/s11665-015-1503-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1503-4