Abstract

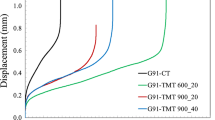

This study focuses on the comparison of mechanical and microstructural properties of induction and conventionally heat-treated steels in the as-quenched state. The investigated steel is a heat treatable 42CrMo4 steel. In order to characterize the mechanical properties, tensile tests and Vickers hardness tests are performed. The yield strength and hardness of the induction hardened condition turn out to be slightly lower compared to the conventionally hardened one. Light optical and scanning electron microscopy show no differences in the martensitic structure of the induction and conventionally hardened condition. However, electron back scatter diffraction investigations reveal a smaller block size within the conventionally hardened specimen. Carbon mappings by electron probe micro analysis show a homogenous carbon concentration in the conventionally hardened and a non-uniform distribution in the induction-hardened case. The segregation of the carbon exhibits line-type features in the induction hardened condition, lowering the total amount of carbon in the matrix. Therefore, the carbon content in the matrix of the conventionally hardened condition is slightly higher, which causes a smaller block size. The smaller block size is believed to be the reason for the higher hardness and yield strength.

Similar content being viewed by others

References

S.T. Ahn, D.S. Kim, and W.J. Nam: J. Mater. Process. Technol. 2005, vol. 160, pp. 54–58

J.B. Lee, N. Kang, J.T. Park, S.-T. Ahn, Y.-D.Park, I.-D.Choi, K.-R.Kim, and K.-M. Cho: Mater. Chem. Phys., 2011, vol. 129, pp. 365–70.

D. Dengel: Haerterei Tech. Mitteilungen, 1984, vol. 39, pp. 182–93.

T. Furuhara, K. Kobayashi, and T. Maki: ISIJ Int., 2004, vol. 44, pp. 1937–44.

S. Murphy and J.H. Woodhead: Metall. Trans., 1972, vol. 3, pp. 727–35.

C. Revilla, P. Uranga, B. Lòpez, and J.M. Rodriguez-Ibabe: AIST Steel Prop. Appl. Conf. Proc. Comb. with MS T’12, Mater. Sci. Technol. 2012, 2012, pp. 267–74.

K. Steineder and R. Schneider: HTM J. Heat Treat. Mater., 2013, vol. 68, pp. 77–84.

H. Leitner, D. Caliskanoglu, and H. Clemens: BHM Berg- Huettenmaenn. Monatsh., 2004, vol. 149, pp. 172–75.

H. Kitahara, R. Ueji, N. Tsuji, and Y. Minamino: Acta Mater., 2006, vol. 54, pp. 1279–88.

S. Morito, H. Yoshida, T. Maki, and X. Huang: Mater. Sci. Eng., A, 2006, vols. 237–40, pp. 237–40.

E. Schacht and J. Richter: Prakt. Metallogr., 1998, vol. 35, pp. 384—95.

H. Matsuda, R. Mizuno, Y. Funakawa, K. Seto, S. Matsuoka, and Y. Tanaka: J. Alloys Compd., 2013, vol. 577, pp. S661-67.

G. Speichand and W. Leslie: Metall. Trans. A, 1972, vol. 3, pp. 1043–53.

J. Wu, P.J. Wray, C.I. Garcia, M. Hua, and A.J. Deardo: ISIJ Int., 2005, vol. 45, pp. 254–62.

F.J. Humphreys: J. Mater. Sci., 2001, vol. 6, pp. 3833–54.

S. Morito, H. Saito, T. Ogawa, T. Furuhara, and T. Maki: ISIJ Int., 2005, vol. 45, pp. 91–94.

G. Miyamoto, N. Iwata, N. Takayama, and T. Furuhara: J. Alloys Compd., 2013, vol. 577, pp. S528–32.

S. Morito, H. Tanaka, R. Konishi, T. Furuhara, and T. Maki: Acta Mater., 2003, vol. 51, pp. 1789–99.

Y. Tomita and K. Okabayashi: Metall. Trans. A, 1986, vol. 17, pp. 1203–09.

T. Swarrand and G. Krauss: Metall. Trans. A, 1976, vol. 7, pp. 41–48.

C. Zhang, Q. Wang, J. Ren, R. Li, M. Wang, F. Zhang, and K. Sun: Mater. Sci. Eng., A, 2012, vol. 534, pp. 339–46.

F. Foroozmehr, A. Najafizadeh, and A. Shafyei: Mater. Sci. Eng., A, 2011, vol. 528, pp. 5754–58.

K.C. Smith, J.P. Wise, and G. Krauss: Prog. Heat Treat. Surf. Eng., 2000, pp. 379–86.

K.D. Clarke, C.J. Van Tyne, C.J. Vigil, and R.E. Hackenberg: J. Mater. Eng. Perform., 2011, vol. 20, pp. 161–68.

Acknowledgments

The financial support by the Austrian Federal Ministry of Economy, Family and Youth and the National Foundation for Research, Technology and Development is gratefully acknowledged. The authors want to thank Tomasz Wojcik for his help regarding the TEM investigations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 3, 2014.

Rights and permissions

About this article

Cite this article

Sackl, S., Leitner, H., Zuber, M. et al. Induction Hardening vs Conventional Hardening of a Heat Treatable Steel. Metall Mater Trans A 45, 5657–5666 (2014). https://doi.org/10.1007/s11661-014-2518-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2518-4