Abstract

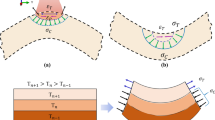

We design, fabricate, and test thin thermally stable metastructures consisting of bi-metallic unit cells and show how the coefficient of thermal expansion (CTE) of these metastructures can be finely and coarsely tuned by varying the CTE of the constituent materials and the unit cell geometry. Planar and three-dimensional finite element method modeling (FEM) is used to drive our design and inform experiments, and predict the response of these metastructures. We develop a robust experimental fabrication procedure in order to fabricate thermally stable samples with high aspect ratios. We use digital image correlation (DIC) and an infrared camera to experimentally measure displacement and temperature during testing and compute the CTE of our samples. The samples, composed of an aluminum core and an external titanium frame, exhibit a CTE of 2.6 ppm/°C, which is significantly lower than either constituent. These unit cells can be assembled over a large area to create thin low-CTE foils. Finally, we demonstrate how the approach developed in this work can be used to fabricate metastructures with CTE’s ranging from −3.6 ppm/°C to 8.4 ppm/°C.

Similar content being viewed by others

References

Kuribara K, Wang H, Uchiyama N, Fukuda K, Yokota T, Zschieschang U, Jaye C, Fischer D, Klauk H, Yamamoto T, Takimiya K, Ikeda M, Kuwabara H, Sekitani T, Loo YL, Someya T (2012) Organic transistors with high thermal stability for medical applications. Nat Commun 3:723. doi:10.1038/ncomms1721

Roy R, Agrawal DK, Mckinstry HA (1989) Very low thermal-expansion coefficient materials. Annu Rev Mater Sci 19:59–81

Ishii J, Akamatsu T (2009) Organo-soluble low CTE polyimides and their applications to photosensitive cover layer materials in flexible printed circuit boards. High Perform Polym 21:123–138. doi:10.1177/0954008308088397

Zweben C (1998) Advances in composite materials for thermal management in electronic packaging. JOM 50:47–51. doi:10.1007/s11837-998-0128-6

Bollero A, Kaupmees L, Raadik T, Grossberg M, Fernandez S (2012) Thermal stability of sputtered Mo/polyimide films and formation of MoSe2 and MoS2 layers for application in flexible Cu(In, Ga)(Se, S)(2) based solar cells. Thin Solid Films 520:4163–4168. doi:10.1016/j.tsf.2011.04.099

Lakes R (1996) Cellular solid structures with unbounded thermal expansion. J Mater Sci Lett 15:475–477

Sigmund O, Torquato S (1996) Composites with extremal thermal expansion coefficients. Appl Phys Lett 69:3203–3205

Sigmund O, Torquato S (1997) Design of materials with extreme thermal expansion using a three-phase topology optimization method. J Mech Phys Solids 45:1037–1067

Steeves CA, Lucato SLDSE, He M, Antinucci E, Hutchinson JW, Evans AG (2007) Concepts for structurally robust materials that combine low thermal expansion with high stiffness. J Mech Phys Solids 55:1803–1822. doi:10.1016/j.jmps.2007.02.009

Steeves CA, Mercer C, Antinucci E, He MY, Evans AG (2009) Experimental investigation of the thermal properties of tailored expansion lattices. Int J Mech Mater Des 5:195–202

Steeves CA, Evans AG (2011) Optimization of thermal protection systems utilizing sandwich structures with low coefficient of thermal expansion lattice hot faces. J Am Ceram Soc 94:s55–s61. doi:10.1111/j.1551-2916.2011.04447.x

Berger J, Mercer C, McMeeking RM, Evansz AG (2011) The design of bonded bimaterial lattices that combine low thermal expansion with high stiffness. J Am Ceram Soc 94:S42–S54. doi:10.1111/j.1551-2916.2011.04503.x

Haynes WM (ed) (2009) CRC handbook of chemistry and physics (CRC handbook of chemistry and physics). CRC Press, Taylor and Francis, Boca Raton

Patterson K, Pellegrino S, Breckinridge J (2010) Shape correction of thin mirrors in a reconfigurable modular space telescope. Space Telescopes and Instrumentation 2010: Optical, Infrared, and Millimeter Wave 7731 doi:10.1117/12.861442

Sutton MA, Wolters WJ, Peters WH, Ranson WF, McNeill SR (1983) Determination of displacements using an improved digital correlation method. Image Vis Comput 1:133–139. doi:10.1016/0262-8856(83)90064-1

Chu TC, Ranson WF, Sutton MA (1985) Applications of digital-image-correlation techniques to experimental mechanics. Exp Mech 25:232–244. doi:10.1007/bf02325092

FLIR. SC6000 Datasheet. Available: http://www.flir.com/thermography/americas/us/view/?id=44791

Brewster MQ (1992) Thermal radiative transfer and properties. Wiley, New York

Kaplan H (2007) Practical applications of infrared thermal sensing and imaging equipment, 3rd edn. SPIE Press, Bellingham

“Vic2D 2009” (ed) (2009) Columbia, SC: Correlated Solutions, Inc

“JMP” (ed) (2007) Cary, NC: SAS Institute Inc

Team RC (2012) “R: a language and environment for statistical computing”. R. F. f. S. Computing (ed). Vienna, Austria

Acknowledgments

This work was supported by the Keck Institute for Space Studies at the California Institute of Technology. Part of this research was carried out at the Jet Propulsion Laboratory, California Institute of Technology, under a contract with the National Aeronautics and Space Administration. We thank Jerry Mulder for support with the laser welding process. We also thank Prof. Sergio Pellegrino and Dr. Namiko Yamamoto for valuable advice and assistance, and Prof. Craig A. Steeves for earlier discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gdoutos, E., Shapiro, A.A. & Daraio, C. Thin and Thermally Stable Periodic Metastructures. Exp Mech 53, 1735–1742 (2013). https://doi.org/10.1007/s11340-013-9748-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-013-9748-z