Abstract

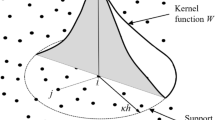

Small punch tests in the extrusion and transverse directions of nanostructured titanium manufactured by hydrostatic extrusion were simulated by means of a multiscale model, which encompasses three length scales. Information is transferred from the microscale (mechanical behavior of each slip system within an ellipsoidal grain) to the mesoscale (polycrystalline aggregate) by means of a model based on elastic and viscoplastic self-consistent approximations. The mechanical response of the polycrystalline aggregate at the mesoscale is used as the constitutive equation of the material at each integration point of the finite element model. The results of the multiscale finite element simulations were in good agreement with the macroscopic experimental results and provided information to understand the dominant deformation and fracture mechanisms at the microscopic level.

Similar content being viewed by others

References

ASTM B 348-09 standard specification for titanium and titanium alloy bar and billers. ASTM International (2013)

Conrad H (1981) Effect of interstitial solutes on the strength and ductility of titanium. Prog Mater Sci 26:123–403

Eskner M, Sandstrom R (2004) Mechanical property evaluation using the small punch test. J Test Eval 32:282–289

Fleury E, Ha JS (1998) Small punch tests to estimate the mechanical properties of steels for steam power plant: I. Mechanical strength. Int J Press Vessels Pip 75:699–706

Gong J, Wilkinson AJ (2009) Anisotropy in the plastic flow properties of single-crystal α-titanium determined from micro-cantilever beams. Acta Mater 57:5693–5705

Gubicza J, Fogarassy Z, Krállics G, Lábár J, Törköly T (2008) Microstructure and mechanical behavior of ultrafine-grained titanium. Mater Sci Forum 589:99–104

Gunderov DV, Polyakov AV, Semenova IP, Raab GI, Churakova AA, Gimaltdinova EI, Sabirov I, Segurado J, Sitdikov VD, Alexandrov IV, Enikeev NA, Valiev RZ (2013) Evolution of microstructure, macrotexture and mechanical properties of commercially pure Ti during ECAP-conform processing and drawing. Mater Sci Eng A 562:128–136

Hajizadeh K, Alamdari SG, Eghbali B (2013) Stored energy and recrystallization kinetics of ultrafine grained titanium processed by severe plastic deformation. Phys B Condens Matter 417:33–38

Kim HS, Yoo SJ, Ahn JW, Kim DH, Kim WJ (2011) Ultrafine grained titanium sheets with high strength and high corrosion resistance. Mater Sci Eng A 528:8479–8485

Knezevic M, Lebensohn RA, Cazacu O, Revil-Baudard B, Proust G, Vogel SC, Nixon ME (2013) Modeling bending of α-titanium with embedded polycrystal plasticity in implicit finite elements. Mater Sci Eng A 564:116–126

Kocks UF, Tome CN, Wenk HR (1998) Texture and anisotropy. Cambridge University Press, New York

Lancaster RJ, Harrison WJ, Norton G (2015) An analysis of small punch creep behavior in the titanium aluminide Ti–45Al–2Mn–2Nb. Mater Sci Eng A 626:263–274

Lebensohn RA, Tomé CN (1993) A self-consistent anisotropic approach for the simulation of plastic deformation and texture development of polycrystals: application to zirconium alloys. Acta Metall Mater 41:2611–2624

Lütjering G, Williams JC (2003) Titanium, vol 2. Springer, New York

Misawa T, Adachi T, Saito M, Hamaguchi Y (1987) Small punch tests for evaluating ductile-brittle transition behavior of irradiated ferritic steels. J Nucl Mater 150:194–202

Moreno-Valle EC, Monclus MA, Molina-Aldareguia JM, Enikeev N, Sabirov I (2013) Biaxial deformation behavior and enhanced formability of ultra-fine grained copper. Metall Mater Trans A 44:2399–2408

Moreno-Valle EC, Pachla W, Kulczyk M, Savoini B, Monge MA, Ballesteros C, Sabirov I (2013) Anisotropy of uni-axial and bi-axial deformation behavior of pure titanium after hydrostatic extrusion. Mater Sci Eng A 588:7–13

Nemat-Nasser S, Guo WG, Nesterenko VF, Indrakanti SS, Gu YB (2001) Dynamic response of conventional and hot isostatically pressed Ti–6Al–4V alloys: experiments and modeling. Mech Mater 33:425–439

Panteghini A, Genna G (2010) Effects of the strain-hardening law in the numerical simulation of wire drawing processes. Comput Mater Sci 49:236–242

Panteghini A, Genna G (2012) Numerical integration of a pressure-dependent, non-linear kinematic hardening constitutive model for large strain cyclic plasticity of metals. Int J Numer Methods Eng 89:1047–1067

Pachla W, Kulczyk M, Sus-Ryszkowska M, Mazur A, Kurzydlowski KJ (2008) Nanocrystalline titanium produced by hydrostatic extrusion. J Mater Process Technol 205:173–182

Rodríguez C, Cárdenas E, Belzunce FJ, Betegón C (2013) Fracture characterization of steels by means of the small punch test. Exp Mech 53:385–392

Rodríguez-Galán D, Sabirov I, Segurado J (2015) Temperature and strain rate effect on the deformation of nanostructured pure Titanium. Int J Plast 70:191–205

Sabirov I, Perez-Prado MT, Molina-Aldareguia JM, Semenova IP, Salimgareeva GKh, Valiev RZ (2011) Anisotropy of mechanical properties in high-strength ultra-fine-grained pure ti processed via a complex severe plastic deformation route. Scr Mater 64:69–72

Salem AA, Kalidindi SR, Doherty RD (2003) Strain hardening of titanium: role of deformation twinning. Acta Mater 51:4225–4237

Segurado J, Lebensohn RA, LLorca J, Tomé CN (2012) Multiscale modeling of plasticity based on embedding the viscoplastic self-consistent formulation in implicit finite elements. Int J Plast 28:124–140

Segurado J, LLorca J (2013) Simulation of the deformation of polycrystalline nanostructured Ti by computational homogenization. Comput Mater Sci 76:3–11

Shin DH, Kim I, Kim J, Kim YS, Semiatin SL (2003) Microstructure development during equal-channel angular pressing of titanium. Acta Mater 51:983–996

Tomé CN, Canova GR, Kocks UF, Christodoulou N, Jonas JJ (1984) The relation between macroscopic and microscopic strain hardening in FCC polycrystals. Acta Metall 32:1637–1653

Tomé CN, Lebensohn RA (2004) Self consistent homogenization methods for texture and anisotropy. In: Raabe D, Roters F, Barlat F, Chen L-Q (eds) Continuum scale simulation of engineering materials: fundamentals-microstructures-process applications. Wiley, Weinheim, pp 473–499

Topolski K, Garbacz H, Pachla W, Kurzydlowski KJ (2010) Bulk nanostructured titanium fabricated by hydrostatic extrusion. Phys Status Solidi (C) 7:1391–1394

Tromans D (2011) Elastic anisotropy of hcp metal crystals and polycrystals. Int J Res Rev Appl Sci 16:462–483

Yu Q, Shan Z-W, Li J, Huang X, Xiao L, Sun J, Ma E (2010) Strong crystal size effect on deformation twinning. Nature 463:335–338

Zaefferer S (2003) A study of active deformation systems in titanium alloys: dependence on alloy composition and correlation with deformation texture. Mater Sci Eng A 344:20–30

Zherebtsov S, Mazur A, Salishchev G, Lojkowski W (2008) Effect of hydrostatic extrusion at 600–700 c on the structure and properties of Ti–6Al–4V alloy. Mater Sci Eng A 485:39–45

Acknowledgments

This work was supported by the European Union 7th Framework Program, project LIMEDU (ERA-NET MATERA+). IS acknowledges the financial support from the Spanish Ministry of Economy and Competitiveness through the Ramón y Cajal Fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ridruejo, A., Segurado, J., Moreno-Valle, E.C. et al. Multiscale modeling of the small punch test in nanostructured Ti. Meccanica 51, 443–453 (2016). https://doi.org/10.1007/s11012-015-0315-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-015-0315-9