Abstract

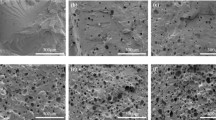

The effects of the filler content and the coupling agent 3-aminopropyltriethoxysilane (3-APE) on the mechanical properties, thermal properties, and morphologies of polylactic acid (PLA)/coconut shell powder (CSP) biocomposites were investigated. It was found that increasing the CSP content decreased the tensile strengths and elongations at break of the PLA/CSP biocomposites. However, incorporating CSP increased their modulus of elasticity. The tensile strengths and modulus of elasticity of the PLA/CSP biocomposites were enhanced by the presence of 3-APE, which can be attributed to a stronger filler–matrix interaction. The thermal stabilities of the biocomposites increased with the filler content, and they were enhanced by 3-APE treatment. Meanwhile, the presence of CSP increased the glass transition temperatures (T g) and crystallinities (X c) of the PLA/CSP biocomposites at a filler content of 30 php. After 3-APE treatment, T g and X c of the PLA/CSP biocomposites increased due to enhanced interfacial bonding. The presence of a peak crystallization temperature (T c) for the PLA/CSP biocomposites indicated that the CSP has a nucleating effect. The melting temperatures (T m) and the T c values of the biocomposites were not significantly affected by the filler content and 3-APE. PLA/CSP biocomposites that had been treated with 3-APE presented the strongest filler–matrix interaction, as confirmed by SEM.

Similar content being viewed by others

References

John MJ, Thomas S (2008) Biofibres and biocomposites. Carbohydr Polym 71:343–364

Averous L, Digabel FL (2006) Properties of biocomposites based on lignocellulosic fillers. Carbohydr Polym 66:480–493

Wu CS (2009) Renewable resource-based composites of recycled natural fibers and maleated polylactide bioplastic: characterization and biodegradability. Polym Degrad Stab 94:1076–1084

Carrosco F, Pages P, Gamez PJ, Satana OO, Maspoch ML (2010) Processing of poly(lactic acid): characterization of chemical structure, thermal stability and mechanical properties. Polym Degrad Stab 95:116–125

Schwark F (2009) Influence factors for scenario analysis for new environmental technologies—the case for biopolymer technology. J Clean Prod 17:644–652

Xie Y, Hill CAS, Xiao Z, Militz H, Mai C (2010) Silane coupling agents used for natural fiber/polymer composites: a review. Compos Part A 41:806–819

Li W, Yang K, Peng J, Zhang L, Guo S, Xia HY (2008) Effects of carbonization temperatures on charecteristics of porosity in coconut shell chars and actived carbons derived from carbonized coconut shell chars. Ind Crop Prod 28:190–198

Pradhan SK, Dwarakadasa ES, Reucroft PJ (2004) Processing and characterization of coconut shell powder filled UHMWPE. Mater Sci Eng A 367:57–62

Bledzki AK, Mamun AA, Volk J (2010) Barley husk and coconut shell reinforced polypropylene composites: the effect of fibre physical, chemical and surface propertie. Compos Sci Technol 70:840–846

Salmah H, Koay SC, Hakimah O (2012) Surface modification of coconut shell powder filled polylactic acid biocomposites. J Thermoplastic Compos Mater (in press). doi:10.1177/0892705711429981

Tserki S, Matzinos P, Kokkou S, Panayiotou C (2005) Novel biodegradable composite based on treat lignocellulosic waste flour as filler. Part I. Surface chemical modification and characterization of waste flour. Compos Part A 36:965–974

John MJ, Anandjiwala RD (2009) Chemical modification of flax reinforced polypropylene composites. Compos Part A 40:442–448.8

Ismail H, Shuhelmy S, Edyham MR (2002) The effects of a silane coupling agent on curing charecteristics and mechanical properties of bamboo fibre filled natural rubber composites. Eur Polym J 38:39–47

Arif MF, Megat-Yusoff PSM, Ahamad F (2009) Effect of chemical treatment on oil palm empty fruit bunch reinforced high density polyethylene composites. J Reinf Plast Compos 29:2105–2118

Bengtsson M, Oksman K (2006) The use of silane technology in crosslinking polyethylene/wood flour composites. Compos Part A 37:752–765

Salmah H, Faisal A, Kamaruddin H (2011) Chemical modification of chitosan filled polypropylene composites: the effect 3-aminopropyltriethoxysilane on mechanical and thermal properties. Int J Polym Mater 60:429–440

Shih YF, Huang CC (2011) Polylactic acid (PLA)/banana fiber (BF) biodegradable green biocomposites. J Polym Res 18:2335–2340

Perinovic S, Andricic B, Erceg M (2010) Thermal properties of poly(L-lactic)/olive stone flour composites. Thermochim Acta 510:97–102

Gregorova A, Hrabalova M, Wimmer R, Saake B, Altaner C (2009) Poly(lactide acid) composites reinforced with fibers obtained from different tissue type of Picea sitchensis. J Appl Polym Sci 114:2616–2623

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chun, K.S., Husseinsyah, S. & Osman, H. Mechanical and thermal properties of coconut shell powder filled polylactic acid biocomposites: effects of the filler content and silane coupling agent. J Polym Res 19, 9859 (2012). https://doi.org/10.1007/s10965-012-9859-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-012-9859-8