Abstract

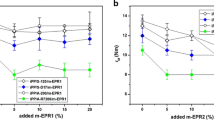

The effect of HP loading on the curing characteristics and mechanical properties of filled SBR and EPDM composites was investigated using bis-(3-triethoxysilylpropyl) tetrasulfide (Si69) as coupling agent. For all composites, 20 phr (part per one hundred parts of rubber) silica was used. The addition of HP enhances the vulcanization process of composites filled with silica. The hybrid reinforcement of HP and silica imparts good stiffness and toughness to filled rubber composites. An excess of HP will tend to form agglomerates in the rubber matrix, which adversely affects the silica-rubber matrix interfacial interaction, and consequently lowers the overall mechanical properties. The HP distribution and filler-rubber matrix interaction, which were analyzed by scanning electron microscopy and equilibrium swelling, explained well the changes in mechanical properties of composites filled with hybrid fillers. Dynamic mechanical analysis indicated that the composites exhibited higher Payne effect and storage modulus, and lower tanδmax value with an increase of HP loading.

Similar content being viewed by others

References

Dweib MA, Hu B, O’Donnel A, Shenton HW, Wool RP (2004) All natural composite sandwich beams for structural applications. Compos Struct 63:147–157

Yamsaengsung W, Sombatsompop N (2009) Interfacial adhesion and molecular diffusion in melt lamination of wood sawdust/ebonite NR and EPDM. Polym Compos 30:248–256

Schutlz DL (1980) Fiber technology: the next generation. Rubber World 183:24–26

Goettler LA, Lambright AJ, Leib RI, Dimauro PJ (1981) Extrusion-shaping of curved hose reinforced with short cellulose fibers. Rubber Chem Technol 54:277–301

John MJ, Francis B, Varughese KT, Thomas S (2008) Effect of chemical modification on properties of hybrid fiber biocomposites. Compos Part A 39:352–363

Ichazo MN, Albano C, Gonzalez J, Perera R, Candal MV (2001) Polyepropylene/ wood flour Composites: treatment and properties. Compos Struct 54:207–214

Evelise FS, Raquel SM, Sǒnia MBN (2009) Effectiveness of maleated- and silanized-pp for coir fiber-filled composites, jounal of reinforced plastic and composites. J Reinf Plast Compos 28:2119–2129

Ichazo MN, Hernández M, Albano C, González J (2006) Curing and physical properties of natural rubber/wood flour composites. Macromol Symp 239:192–200

Geethamma VG, Mathew KT, Lakshminarayanan R, Thomas S (1998) Composite of short coir fibres and natural rubber: effect of chemical modification, loading and orientationof fibre. Polymer 39:1483–1491

Zurina M, Ismail H, Bakar AA (2004) Rice husk powder–filled polystyrene/ styrene butadiene rubber blends. J Appl Polym Sci 92:3320–3332

Kumar RP, Amma MLG, Thomas S (1995) Short sisal fiber reinforced styrene- butadiene rubber composites. J Appl Polym Sci 58:597–612

Praveen S, Chattopadhyay PK, Jayendran S, Chakraborty BC, Chattopadhyay S (2010) Effect of nanoclay on themechanical and damping properties of aramid short fibre-filled styrene butadiene rubber composites. Polym Int 59:187–197

Ismail H, Abdul-Khalil HPS (2001) The effects of partial replacement of oil palm wood flour by silica and silane coupling agent on properties of natural rubber compounds. Polym Test 20:33–41

Radovanović B, Marković G, Radovanovic A (2008) Wood flour as a secondary filler in carbon black filled of styrene butadiene/chlorosulphonated olyethylene rubber blend. Polym Compos 29:692–697

Lin CJ, Hergenrother WL, Alexanian E, Böhm GGA (2002) On the filler flocculation in silica-filled rubbers part I:quantifying and tracling the filler flocculation and polymer-filler interactions in the unvulcanized rubber compounds. Rubber Chem Technol 75:865–896

Menon ARR, Aigbodion AI, Pillai CKS, Mathew NM, Bhagwan SS (2002) Processability characteristics and physic-mechanical properties of natural rubber modified with cashewnut shell liquid and cahsewnut shell liquid-formaldehyde resin. Eur Polym J 38:163–168

Flory PJ, Rehner J (1943) Statistical mechanics of cross-linked polymer networks II. Swelling. J Chem Phys 11:521–526

Deng JS, Isayev I (1991) Injection molding of rubber compounds: experimentma- tion and simulation. Rubber Chem Technol 64:296–324

Brandrup J, Immergut EH, Grulke EA (1999) Polymer handbook (vol 1), 4th edn. Wiley-Interscience, Newwork

Parks CR, Brown RJ (1976) Crosslink density of elastomers. A new gas-chromatographic method. Rubber Chem Technol 49:233–236

Wang MJ (1998) Effect of polymer-filler and filler-filler interactions on dynamic properties of filled vulcanizates. Rubber Chem Technol 71:520–589

Pothan LA, Oommen Z, Thomas S (2003) Dynamic mechanical analysis of banana fiber reinforced polyester composites. Compo Sci Technol 63:283–293

Wong S, Shanks R, Hodzic A (2004) Interfacial improvement in poly (3-hydroxybutyrate)–flax fibre composites with hydrogen bonding additives. Compos Sci Technol 64:1321–1330

Joshi M, Maiti SN, Misra A (1994) Studies on the thermal, dynamic mechanical and rheological behavior of short-glass-fiber-reinforced composite based on poly(butylene terephthalate) high density polyethylene blends. Polymer 35:3679–3685

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Wu, W., Wang, W. et al. Preparation and characterization of hemp hurd powder filled SBR and EPDM elastomers. J Polym Res 18, 1023–1032 (2011). https://doi.org/10.1007/s10965-010-9503-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-010-9503-4