Abstract

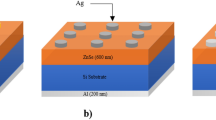

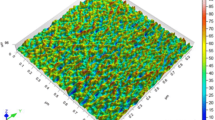

The purpose of this study was to analyze surface topography of Pt Schottky contacts on quaternary n-Al0.08In0.08Ga0.84N thin film. To understand how the effect of temperature changes the layers surface, the surface topography was characterized through atomic force microscopy (AFM) and fractal analysis. Pt Schottky contacts grown on nanostructure Al0.08In0.08Ga0.84N thin film grown by molecular beam epitaxy technique on sapphire substrate at annealing temperatures range of 300–500 °C were used. AFM analysis was performed in contact mode, on square areas of 10 × 10 μm2, by using a Nanosurf Easyscan 2 AFM system. Detailed surface characterization of the surface topography was obtained using statistical parameters of 3D surface roughness, according with ISO 25178-2: 2012, provided by the AFM software. The results revealed that the high quality Schottky contact with the Schottky barrier heights and ideality factor of 0.76 and 1.03 respectively can be obtained under 30 min annealing at 400 °C in N2 ambience. The surface roughness of Pt Schottky contacts on quaternary n-Al0.08In0.08Ga0.84N thin film revealed a fractal structure at nanometer scale. Results obtained by fractal analysis confirm the relationship between the value of the fractal dimension and the statistical surface roughness parameters. AFM and fractal analysis are accurate tools that may assist manufacturers in developing Pt Schottky contacts on quaternary n-Al0.08In0.08Ga0.84N thin film with optimal surface characteristics and provides different yet complementary information to that offered by traditional surface statistical parameters.

Similar content being viewed by others

References

J.R. Chen, T.S. Ko, P.Y. Su, T.C. Lu, H.C. Kuo, Y.K. Kuo, S.C. Wang, Numerical study on optimization of activelayer structures for GaN/AlGaN multiple-quantum-well laser diodes. J. Lightwave Technol. 26(17), 3155–3165 (2008)

R. Werner, M. Reinhardt, M. Emmerling, A. Forchel, V. Harle, A. Bazhenov, High-resolution patterning and characterization of optically pumped first-order GaN DFB lasers. Physica E 7, 915–918 (2000)

V. Rajagopal, M. Ravinandan, P. Koteswara, C.J. Choi, Effects of thermal annealing on the electrical and structural properties of Pt/Mo Schottky contacts on n-type GaN. J. Mater. Sci.: Mater. Electron. 20(10), 1018–1025 (2009)

J. Wang, D.G. Zhao, Y.P. Sun, L.H. Duan, Y.T. Wang, S.M. Zhang, H. Yang, S. Zhou, M. Wu, Thermal annealing behaviour of Pt on n-GaN Schottky contacts. J. Phys. D Appl. Phys. 36(8), 1018–1022 (2003)

C.L. Yu, C.H. Chen, S.J. Chang, P.C. Chang, GaN metal-semiconductor-metal ultraviolet photo detectors with Ir/Pt contact electrodes. J. Electrochem. Soc. 154(2), J71–J72 (2007)

Y.C. Lee, Z. Hassan, M.J. Abdullah, M.R. Hashim, K. Ibrahim, Dark current characteristics of thermally treated contacts on GaN-based ultraviolet photo detectors. Microelectron. Eng. 81, 262–267 (2005)

V.R. Reddy, M. Ravinandan, P.K. Rao, C.J. Choi, Electrical and structural properties of rapidly annealed Pd/Mo Schottky contacts on n-type GaN. Semicond. Sci. Technol. 23(9), 095026 (2008)

I. Vurgaftman, J.R. Meyer, L.R. Ram-Mohan, Band parameters for III-V compound semiconductors and their alloys. J. Appl. Phys. Rev. 89(11), 5815–5875 (2001)

A.J. Ghazai, H. Abu Hassan, Z. Hassan, A.S. Hussein, Effects of thermal annealing of Pt Schottky contacts on quaternary n-Al0.08In0.08Ga0.84N thin film. J. Optoelectron. Adv. M. 6(1–2), 324–326 (2012)

B. Bhushan, Introduction to Tribology, 2nd edn. (John Wiley & Sons Ltd., New York, 2013)

R.K. Leach, Fundamental principles of engineering nanometrology (Elsevier Inc., Oxford, 2010)

P. Sahoo, T. Barman, J.P. Davim, Fractal Analysis in Machining (Springer-Verlag, Heidelberg, 2011)

S. Stach, J. Cybo, Multifractal description of fracture morphology: theoretical basis. Mater. Charact. 51(1), 79–86 (2003)

B.B. Mandelbrot, The Fractal Geometry of Nature (Freeman W. H, San Francisco, 1982)

C.Q. Yuan, J. Li, X.P. Yan, Z. Peng, The use of the fractal description to characterize engineering surfaces and wear particles. Wear 255(1–6), 315–326 (2003)

B.N. Persson, O. Albohr, U. Tartaglino, A.I. Volokitin, E. Tosatti, On the nature of surface roughness with application to contact mechanics, sealing, rubber friction and adhesion. J. Phys.: Condens. Matter 17(1), R1–R62 (2005)

R.P. Yadav, S. Dwivedi, A.K. Mittal, M. Kumar, A.C. Pandey, Fractal and multi fractal analysis of LiF thin film surface. Appl. Surf. Sci. 261, 547–553 (2012)

Ş. Ţălu, Mathematical methods used in monofractal and multifractal analysis for the processing of biological and medical data and images. Anim. Biol. Anim. Husb. 4(1), 1–4 (2012)

J. Schmähling, Statistical characterization of technical surface microstructure, Ph.D. Thesis (University of Heidelberg, Germany, 2006)

S. Lou, X. Jiang, P.J. Scott, Application of the morphological alpha shape method to the extraction of topographical features from engineering surfaces. Measurement 46(2), 1002–1008 (2013)

MountainsMap® 7 Software (Digital Surf, Besançon, France). Available from: http://www.digitalsurf.fr (last accessed August 10, 2013)

ISO 25178-2, Geometrical product specifications (GPS)—Surface texture: Areal –Part 2: Terms, definitions and surface texture parameters. Available from: http://www.iso.org (last accessed August 10, 2013)

Product catalog. Available from: http://www.nanosurf.com/ (last accessed August 10, 2013)

Silicon AFM Probes. Available from: http://www.vistaprobes.com (last accessed August 10, 2013)

SPIP, The Scanning Probe Image Processor, Denmark, 2013. Available from: http://www.imagemet.com (last accessed August 10, 2013)

GraphPad InStat software, version 3.20 (GraphPad, San Diego, CA). Available from: http://www.graphpad.com/instat/instat.htm (last accessed August 10, 2013)

Acknowledgments

The authors would like to thank Universiti Sains Malaysia USM, 11800 Penang, Malaysia for the financial support under 1001/PFIZIK/843088 grant and Science College, Thi-Qar University, Al-Muntazah, Nassiriya 00964, Iraq to conduct this research. Neither author has a financial or proprietary interest in any material or method mentioned

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The statistical parameters of 3D surface roughness, according with ISO 25178-2:2012 are defined as following [22].

-

a)

Height parameters are a class of surface finish parameters that quantify the Z-axis perpendicular to the surface.

-

(Sq)—root mean square height is the standard deviation of the height distribution, or RMS surface roughness.

-

(Ssk)—Skewness is the third statistical moment, qualifying the symmetry of the height distribution. Negative skew indicates a predominance of valleys, while positive skew is seen on surfaces with peaks.

-

(Sku)—Kurtosis is the fourth statistical moment, qualifying the flatness of the height distribution. For spiky surfaces, Sku > 3; for bumpy surfaces, Sku < 3; perfectly random surfaces have kurtosis of 3.

-

(Sp)—Maximum peak height is the height between the highest peak and the mean plane.

-

(Sv)—Maximum pit height is the depth between the mean plane and the deepest valley.

-

(Sz)—Maximum height is the height between the highest peak and the deepest valley.

-

(Sa)—Arithmetical mean height is the mean surface roughness.

-

b)

Functional parameters are calculated from the Abbott-Firestone curve obtained by the integration of height distribution on the whole surface.

-

(Smr)—Areal material ratio is the bearing area ratio at a given height. Ratio of the area of the material at a specified height c (cut level) to the evaluation area. The Smr(c) is expressed as a percentage. For the Smr parameter, the height c is counted by default from the mean plane.

-

(Smc)—Inverse areal material ratio is the height c at which a given areal material ratio p is satisfied. The height is calculated from the mean plane.

-

(Sxp)—Extreme peak height is the difference in height between q and p % material ratio. This parameter must be configured with two thresholds entered in %.

-

c)

Spatial parameters describe topographic characteristics based upon spectral analysis. They quantify the lateral information present on the X- and Y-axes of the surface.

-

(Sal)—Auto-correlation length is the horizontal distance of the autocorrelation function (tx, ty) which has the fastest decay to a specified value s, with 0 < s < 1. The default value for s in the software is 0.2. This parameter expresses the content in wavelength of the surface. A high value indicates that the surface has mainly high wavelengths (low frequencies).

-

(Str)—Texture-aspect ratio is the ratio of the shortest decrease length at 0.2 from the autocorrelation, on the greatest length. This parameter has a result between 0 and 1. If the value is near 1, we can say that the surface is isotropic, i.e. has the same characteristics in all directions. If the value is near 0, the surface is anisotropic, i.e. has an oriented and/or periodical structure.

-

(Std)—Texture direction calculates the main angle for the texture of the surface, given by the maximum of the polar spectrum. This parameter has a meaning if Str is lower than 0.5.

-

d)

Hybrid parameters are a class of surface finish parameters that quantify the information present on the X-, Y- and Z-axes of the surface, i.e. those criteria that depend both on the amplitude and the spacing, such as slopes, curvatures, etc.

-

(Sdq)—Root mean square gradient is the root-mean-square slope of the surface.

-

(Sdr)—Developed interfacial area ratio is the ratio of the increment of the interfacial area of the scale limited surface within the definition area over the definition area. The developed surface indicates the complexity of the surface thanks to the comparison of the curvilinear surface and the support surface. A completely flat surface will have a Sdr near 0 %. A complex surface will have a Sdr of some percents.

-

e)

Functional volume parameters are typically used in tribological studies. They are calculated using the Abbott-Firestone curve (areal material ratio curve) calculated on the surface.

-

Vm(p)—Material volume is the volume of the material at a material ratio p (in %).

-

Vv(p)—Void volume is the volume of the voids at a material ratio p (in %).

-

Vmp—Peak material volume of the scale limited surface is the volume of material in the peaks, between 0 % material ratio and a material ratio p (in %), calculated in the zone above c1. Vmp = Vm(p)

-

Vmc—Core material volume of the scale limited surface is the volume of material in the core or kernel, between two material ratios p and q (in %), calculated in the zone between c1 and c2. Vmc = Vm(q)—Vm(p)

-

Vvc—Core void volume of the scale limited surface is the volume of void in the core or kernel, between two material ratios p and q (in %), calculated in the zone between c1 and c2. Vvc = Vv(p)—Vv(q)

-

Vvv—Pit void volume of the scale limited surface is the volume of void in the valleys, between a material ratio p (in %) and 100 % material ratio, calculated in the zone below c2. Vvv = Vv(p)

-

f)

Feature parameters are derived from the segmentation of a surface into motifs (hills and dales). Segmentation is carried out in accordance with the watersheds algorithm.

-

Spd—Density of peaks is the number of peaks per unit area.

-

Spc—Arithmetic mean peak curvature is the arithmetic mean of the principle curvatures of peaks within a definition area.

-

S10z—Ten point height is the average value of the heights of the five peaks with the largest global peak height added to the average value of the heights of the five pits with the largest global pit height, within the definition area. S10z = S5p + S5v

-

S5p—Five point peak height is the average value of the heights of the five peaks with the largest global peak height, within the definition area.

-

S5v—Five point pit height is the average value of the heights of the five pits with the largest global pit height, within the definition area.

-

Sda—Closed dale area is the average area of dales connected to the edge at height c.

-

Sha—Closed hill area is the average area of hills connected to the edge at height c.

-

Sdv—Closed dale volume is the average volume of dales connected to the edge at height c.

-

Shv—Closed hill volume is the average volume of hills connected to the edge at height c.

Rights and permissions

About this article

Cite this article

Ţălu, Ş., Ghazai, A.J., Stach, S. et al. Characterization of surface roughness of Pt Schottky contacts on quaternary n-Al0.08In0.08Ga0.84N thin film assessed by atomic force microscopy and fractal analysis. J Mater Sci: Mater Electron 25, 466–477 (2014). https://doi.org/10.1007/s10854-013-1611-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-013-1611-6