Abstract

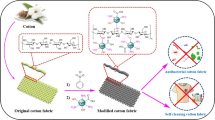

Zinc oxide nanoparticles were prepared and subsequently deposited onto the surface of the cotton fiber by ultrasonic irradiation. The optical, structure and morphology of the coated and un-coated cotton were examined by UV, fourier transform infrared spectroscopy, X-ray diffraction analysis (XRD) and scanning electron microscope (SEM)/Energy Dispersive X-ray analysis. XRD analysis revealed the presence of the crystalline metal oxide of hexagonal phase with an average crystallite size of 12 nm. These nanoparticles are probably physically adsorbed onto the cotton fiber surface. SEM analysis showed a distribution of ZnO nanorod assemblies of various diameters and lengths physically adsorbed onto the cotton fiber surface may take place. The ZnO-cotton fiber nano-composite were tested against Escherichia coli (gram negative) and Staphylococcus aureus (gram positive) cultures, and showed a significant antimicrobial activity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Zinc oxide (ZnO), with a wide band gap of 3.4 eV and a large exciton binding energy of 60 meV, has attracted considerable attentions and is recognized as one of the most promising semiconductor materials in electronic and photonic applications [1]. Preparation and applications of nano metal oxide coatings onto cotton and glass substrates have received much attention in recent years due to its promising applications [2–9]. There is a growing awareness of the use of antibacterial fabrics in the form of medical clothes, protective garments, and bed spreads to minimize the chance of the nosocomial infections [10]. Nanoparticles are much more active than larger one because of their higher surface area and they display unique physical and chemical properties [11]. Textiles coated with silver nanoparticles have become quite common [12]. ZnO nanoparticles is very efficient in impart of antibacterial effect to fabric [13, 14], they are currently being tested as antibacterial agent against Escherichia coli (gram negative) and Staphylococcus aureus (gram positive) cultures. An important aspect of the use of ZnO as antibacterial agent is the requirement that the particles are not toxic to human cell [15, 16]. Although the exact mechanism has not yet been clearly elucidated, the suggested mechanisms include: the role of reactive oxygen species (ROS) generated on the surface of the particles [15] zinc ion release [16] and formation of H2O2 [17] remain possibilities.

There were two general routes to impregnated ZnO nano particles onto the cotton fiber, the first route in which the prepared ZnO nano crystals, were coated onto cotton fibers simply by cure process [6]. The second route was to use the ultrasonic irradiation as an effective method for the deposition of nano materials onto the surface of cotton fibers and other substrates [5, 18–24]. Perelshtein and others have previously used the second route to impregnated some metal oxides ricated nanoparticles onto fabricated cotton materials [5]. In this research the ZnO nanoparticles were impregnated and deposited on/into the natural cotton fibers by irradiation of ultrasound vibrations, so many multi–applications could be addressed. In our previous article we reported the preparation of nanopartiles CuO-coated cotton composite and its application [24]. The aim of the present research was to produce ZnO nanoparticles coated onto nature cotton fibers and to estimate its antibacterial properties against E. coli and S. aureus. ZnO nanoparticles act as antibacterial agent, while cotton act as a substrate which can be used to fabricat medical clothes. Scanning electron microscope (SEM) and X-ray diffraction analysis (XRD) were used to reveal information about the sample, including external morphology, chemical composition, and crystalline structure and orientation of materials making up the sample. Energy dispersive X-ray (EDX) was applied to identify the atomic percentage contents of the main formulation’s elements, that has been applied in coating using EDX unit connected to the SEM microscope. Fourier transform infrared spectroscopy (FTIR) and UV–Visible spectra were used to confirm the formation of ZnO nanoparticles onto the cotton fibers.

2 Experimental

2.1 Materials and instrumentals

Zinc sulfate, sodium hydroxide and ethanol were purchased from MERCK and used without further purification. Cotton was purchased from local market as an Egyptian cotton product. The UV spectra of ZnO were recorded on a SHIMADZU-1601 UV–VIS spectrophotometer in the range 200–800 nm. The infrared spectra for the ZnO coated materials were recorded on a SHIMADZU-1802 FTIR spectrophotometer, using KBr disk in the range 4,000–400 cm−1. Chemical analysis of the ZnO-coated cotton fibers was obtained by Energy Dispersive X-ray spectroscopy (EDX) using an Oxford on X-Max (area:20 mm2) detector installed on a Hitachi S3400N Scanning Electron Microscope (SEM). Calibration of the instrument was performed on Ti Ka at 4.509 keV. Powder X-ray diffraction (XRD) study was performed on a Bruker D8 Advance Diffractometer using Cu-Kα radiation (λ = 0.15418 nm at 45 kV and 40 mA, 0.05 step size and 60 s step time over arrange of 0° to 80°.

2.2 Coating procedure

Cotton fibers were first washed in a water bath containing 5 % of sodium dodecyl sulfate (SDS) at 40 °C for an hour. After rinsing with distilled water, the fibers were dried in vacuum at 60 °C for 24 h. The ZnO-coated cotton material were prepared as follows: 0.05 g dry cotton was first soaked into 10 ml of distilled water containing 0.12 g of ZnSO4·5H2O solution in a sonicated flask and irradiated for 10 min with Ultrasonic Senerator Model US-150 Ti-horn (20 kHz, output 10 Turning 7). 0.06 g of NaOH was added to the mixture under stirring. The mixture was then resonicated at 35–40 °C for one hour. The bath temperature was kept at a constant temperature around 40 °C. The product was then washed thoroughly several times with distilled water to remove any excess of hydroxide and dried in vacuum at 60 °C overnight. The Zinc concentration in the fiber was determined by titration method (3–4 wt%).

2.3 Antibacterial activity screening

The antimicrobial activity of cotton coated with ZnO nanoparticles was tested against gram negative and gram positive bacteria. A small piece of cotton coated with ZnO nanoparticles was added to a tube containing 5 ml of freshly prepared brain heart infusion broth BHIB, (HiMedia, India) that is inoculated with E. coli and S. aureus (these are clinical isolates were kindly provided by the Microbiology laboratory of Al-Shifa hospital). The tubes were incubated at 37 °C for 24 h. The turbidity of the test tubes was compared visually to an uninoculated (control) BHIB tube. 100 μl of each tube was diluted and fractions were plated on Nutrient Agar plates and incubated at 37 °C for 24 h. Colony forming units/ml was calculated by multiplying the number of colonies by the dilution factor.

3 Results and discussion

3.1 Synthesis

The ZnO-coated fibers were obtained by deposition of ZnO nanoparticles onto the cotton fibers via the ultrasound irradiation of metal hydroxide according to the reaction:

During the formation process, the fresh product Zn(OH)2 is dissolved immediately with superfluous OH− and Zn(OH) 2−4 is formed. According to the phase stability diagram of ZnO [22, 23], the formed Zn(OH) 2−4 would change to ZnO nanoparticles at certain pH value (between 8.5 and 12.5) of the reaction solution. The ZnO nanoparticles produced by the reaction were probably physically adsorbed onto the surface of the cotton fibers by the sonochemical microjets resulting from the collapse of sonochemical bubles [5]. These nanoparticles are strongly physically adsorbed onto the cotton substrate, since these particles are not removed by several washings. But it is found that some ZnO nanoparticles which weakly adsorbed onto the cotton fibers are leached out during the first five washings, therefore it is suggested that the coated cotton composite should be washed before drying. They are also very stable at pH 3–6, but they are less stable at pH <3, where most ZnO particles are reacted with the acidic solution.

3.2 XRD results

X-ray diffraction analysis revealed the presence of the crystalline metal oxide on the cotton fibers (Fig. 1). The pattern corresponds to the hexagonal phase of ZnO [25], however they are rather broad because of the nanosized crystallites. The pattern can be indexed for diffractions from the (10 0), (0 0 2), (1 0 1), (1 0 2), (1 1 0), (1 0 3) and (112) planes of wurtzite crystals. The lattice parameters a and c of the samples are calculated using the formula:

θ is the diffraction angle, λ is incident wavelength (λ = 0.15406 nm) and h, k and l are all Miller indices. The calculation of the lattice parameters is based on whole-spectra fitting method for all peaks by using software. The lattice parameters of coated ZnO nanoparticles are a = b = 0.3249 nm and c = 0.52008 nm. Scherer’s equation was used to estimate mean crystallite size.

where P is the mean diameter of nanoparticles, λ is the wavelength of X-ray radiation source, and β is the corrected angular full width at half maximum of the X-ray diffraction peak at the diffraction angle. The average crystallite size of zinic oxide nanoparticles estimated by XRD data was around 12 nm which is very close to the reported values of similar ZnO coated cotton materials [4, 26]. The almost very similar calculated crystallite sizes for the five main peaks(Table 1) may provide evidence that a sphere crystallite shape of ZnO are more probable.

3.3 SEM and EDX results

The morphology of the fiber surface before and after deposition of ZnO nanoparticles was studied by SEM and is presented in Fig. 2. On the SEM image of the original cotton fiber (Fig. 2a), grooves and fibrils could be easily observed on the surface of the fiber. Fig. 2b presents the SEM photographs of ZnO nanoparticles coated onto cotton fibers after sonication. It is likely to say that, cotton fibers were covered with ZnO nanoparticles. The SEM analysis revealed that the size of ZnO nanoparticles coated onto cotton fibers was in the nanoscale range. From Fig. 2a, it is clear that the size of the cotton fibers is in the range of 200 μm, but the size of the ZnO nanoparticles coated on the fibers is much smaller of a nanoscale level about 20 nm as calculated from the ultraviolet spectra. In certain conditions where probably, a slow growth of ZnO nanoparticles, it is found that nanorod crystals of various sizes as well as assemblies of well defined flower of nanorods of various diameters ranging from 100 to 500 nm and various length from 500 nm to few micrometers is clearly showed in SEM image Fig. 2c. That is in agreement with previously reported results [27]. Figure 3 shows the EDX spectra of the ZnO coated cotton samples. The chemical composition of the ZnO-coated cotton samples are presented in Fig. 3. EDX spectrum of the ZnO coated cotton composite showed both Zn and O components. The presence of Zn atoms in the coated cotton fibers indicates that ZnO is deposited onto it.

3.4 UV–VIS and FTIR spectra

The structure of the nanoparticles was further examined UV–VIS and FTIR spectroscopy. The UV visible spectrum of the ethanolic solution of ZnO nanoparticles shows an absorption band at 359 nm (Fig. 4). The energy calculated according to the Planck’s constant is 3 × 4 eV. The FTIR spectrum of the immobilized ZnO nanoparticles coated onto cotton shows an absorption band at 465 cm−1 is typically due to the lattice vibrations of Zn–O bond, The strong band at 1,090 cm−1 can be assigned to asymmetric stretching vibration of Zn–O–Zn bridging. The broad band at 3,435 cm−1 is due the O–H stretching and the absorption band at 1,550 cm−1 bending of the hydroxyl groups of some Zn(OH)2 and/or physically adsorbed water molecules [28].

3.5 Antibacterial activity

The antibacterial activity of ZnO nanoparticles coated onto cotton against E. coli microorganisms are shown in Fig. 5. The coated cotton sample displays high activity with a great reduction of bacteria (Fig. 5). No growth was observed in the tube containing the ZnO coated cotton as evident by the clear appearance of the tube and the absence of growth from the subcultured samples. Similar results were observed against S. aureus (Table 2).

4 Conclusion

ZnO nanoparticles were deposited onto cotton fibers by ultrasonic irradiation. The morphology and structure of the ZnO coated cotton fibers were examined by XRD, SEM/EDX, FTIR and UV visible spectra. XRD analysis revealed the presence of the crystalline metal oxide of hexagonal phase on the cotton fibers. SEM analysis showed that different forms of ZnO nanoparticles were developed which may be dependent on the chemical conditions; and physical environment during the growing. These materials can be used as antibacterial fabrics in the form of medical cloths, protective garments and bed spreads and other many purposes to minimize the chance of nosocomial infections. Since ZnO is used in the form of nanoparticle, it will have a very good absorption, penetration and availability. It showed a great reduction in the bacteria activity.

References

M.H. Huang, S. Mao, H. Feick, H. Yan, Y. Wu, H. Kind et al., Science 292, 1897 (2001)

H. Wang, A. Zakirov, S.U. Yuldashev, J. Lee, F. Dejun, T. Kang, Mater. Lett. 65, 1316 (2011)

Gadi Borkow, Jeffrey Gabbay, Curr. Chem. Biol. 3, 272–278 (2009)

O.V. Abramov, A. Gedanken, Y. Koltypin, N. Perkas, I. Perelshtein, E. Joyce, T.J. Mason, Surf. Coat. Technol. 204, 718–722 (2009)

I. Perelshtein, G. Applerot, N. Perkas, E. Wehrschetz-Sigl, A. Hasmann, G. Guebitz, A. Gedanken, Surf. Coat. Technol. 204, 54 (2009)

S. Sule, M. Sarnsik, A.H. Aktas, M.C. Ucar, E. Erden, Nanoscale Res. Lett. 5, 1204–1210 (2010)

B. Xu, Z. Cai, Appl. Surf. Sci. 254, 5899–5904 (2008)

J. Zhao, Z.G. Jin, T. Li, X.X. Liu, Appl. Surf. Sci. 252, 8287 (2006)

N. Neamjan, W. Srichanussn, P. Threepopnatkul, J. Nanosci Technol. 12, 525 (2012)

S. Wang, W. Hou, L. Wei, H. Jia, X. Liu, B. Xu, Surf. Coat. Technol. 202, 460–465 (2007)

C.Y. Chen, C.L. Chiang, Materials Lett. 62, 3607–3609 (2008)

N. Duran, P.D. Marcarto, G.I.H. De Souza, O.L. Alves, E. Esposito, J. Biomed. Nanotechnol. 3, 203–208 (2007)

G. Applerot, A. Lipovsky, R. Dror, N. Perkas, Y. Nitzan, R. Lubart et al., Adv. Funct. Mater. 19, 1–11 (2009)

Z. Huang, X Zheng, D Yan, G Yin, X Liao, Y Kang, et al., Langmuir 15, 4140–4144. J. Nanoparticle Res. 9, 479–489 (2008)

S. Nair, A. Sasidharan, VV. Divya Rani, D. Menon, S. Nair. K. Manzoor, J. Mater. Sci. Mater. Med. (2008) (online first).

J. Sawai, E. Kawada, F. Kanou, H. Igarashi, A. Hashimoto, T. Kokugan et al., J. Chem. Eng. Jpn. 29, 627–633 (1996)

J. Sawai, H. Kojima, H. Igarashi, A. Hashimoto, S. Shoji, A. Takehara et al., J. Chem. Eng. Jpn. 30, 1034–1039 (1997)

J. Sawai, S. Shouji, H. Igarashi, A. Hashimoto, T. Kokugan, M. Shimizu et al., J. Ferment. Bioeng.86, 521 (1998)

A. Gedanken, Ultrason. Sonochem. 11, 47 (2004)

V.G. Pol, G. Wildermuth, J. Felsche, A. Gedanken, J. Calderon-Moreno, J. Nanosci. Nanotech. 5, 975 (2006)

V.G. Pol, A. Gedanken, J. Calderon-Moreno, Chem. Mater. 15, 1111 (2003)

N. Perkas, G. Amirian, S. Dubinsky, S. Gazit, A. Gedanken, J. Appl. Polym. Sci. 1042, 1423 (2007)

R.H. Wang, J.H. Xin, X.M. Tao, W.A. Daoud, Chem. Phys. Lett. 398, 250 (2004)

I.M. Elnahhal, S.M. Zourab, F. Kodeh, F. Babonneau et al., Intern. Nano Lett. 2, 62 (2012)

O. Garcia-Martinez et al., Solid State Ionic 63, 442 (1993)

S. Yamabi, H. Imai, J. Mater. Chem. 12, 3773 (2002)

A. Bagreev, S. Bashkova, D.C. Locke, T.J. Bandos, Environ Sci Tech 35, 1537–1543 (2001)

M. Yeganeh Ghotbi, J. Alloy. Compd. 491, 420–422 (2010)

Acknowledgments

The authors would like to thank the French Government for the Al-maqdisi grant jointly with the Palestinian Ministry of Higher Education.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

El-Nahhal, I.M., Zourab, S.M., Kodeh, F.S. et al. Nano-structured zinc oxide–cotton fibers: synthesis, characterization and applications. J Mater Sci: Mater Electron 24, 3970–3975 (2013). https://doi.org/10.1007/s10854-013-1349-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-013-1349-1