Abstract

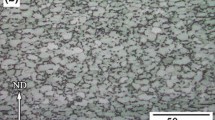

To ascertain the influence of severe plastic deformation (SPD) on a Ti–Nb–Ta–Zr (TNTZ) alloy, we studied the room temperature mechanical behavior and microstructural evolution of an ultrafine-grained (UFG) Ti–36Nb–2Ta–3Zr (wt%) alloy prepared via equal-channel angular pressing (ECAP) of the as-hot-extruded alloy. The tensile behavior, phase composition, grain size, preferred orientation, and dislocation density of the UFG alloy, processed under different conditions, were analyzed and discussed. Compared to the as-hot-extruded alloy, the ECAP-processed TNTZ alloy (3 passes) exhibited approximately 40 and 88 % increase in average ultimate strength and yield strength, respectively. Moreover, as the number of ECAP passes increased from 3 to 6, the TNTZ alloy exhibited not only the expected increase in ultimate and yield strength values, but also a slight increase in elongation. Our results suggest that the deformation mechanisms that govern the behavior of the as-hot-extruded coarse grained (CG) TNTZ alloy during ECAP involve a combination of stress-induced martensitic transformation and dislocation activity. In the case of the ECAP-processed UFG TNTZ alloy, the deformation mechanism is proposed to involve two components: first, dislocation activity induced by the strain field imposed during ECAP; and second, the formation of α″ martensite phase during the early stages of ECAP which eventually transforms into β phase during continued deformation. We propose that the deformation mechanism governing the room temperature behavior of the TNTZ alloy strongly depends on the grain size of the β phase.

Similar content being viewed by others

References

Geetha M, Singh AK, Asokamani R, Gogia AK (2009) Ti based biomaterials, the ultimate choice for orthopaedic implants—a review. Prog Mater Sci 54(3):397–425

Elias LM, Schneider SG, Schneider S, Silva HM, Malvisi E (2006) Microstructural and mechanical characterization of biomedical Ti–Nb–Zr(–Ta) alloys. Mater Sci Eng, A 432(1–2):108–112

Kuroda D, Niinomi M, Morinaga M, Kato Y, Yashiro T (1998) Design and mechanical properties of new β type titanium alloys for implant materials. Mater Sci Eng, A 243(1–2):244–249

Sakaguchi N, Niinomi M, Akahori T, Takeda J, Toda H (2005) Relationships between tensile deformation behavior and microstructure in Ti–Nb–Ta–Zr system alloys. Mater Sci Eng, C 25(3):363–369

Kanetaka H, Hosoda H, Shimizu Y, Kudo T, Zhang Y, Kano M, Sano Y, Miyazaki S (2010) In vitro biocompatibility of Ni–free Ti–based shape memory alloys for biomedical applications. Mater Trans 51(10):1944–1950

Congqin N, Dongyan D, Kerong D, Wanyin Z, Lei C (2010) The effect of Zr content on the microstructure, mechanical properties and cell attachment of Ti–35Nb–xZr alloys. Biomed Mater 5 (4):045006 (045008 )–045006 (045008)

Hallab NJ, Vermes C, Messina C, Roebuck KA, Glant TT, Jacobs JJ (2002) Concentration- and composition-dependent effects of metal ions on human MG-63 osteoblasts. J Biomed Mater Res 60(3):420–433

Niinomi M (2003) Fatigue performance and cyto-toxicity of low rigidity titanium alloy, Ti–29Nb–13Ta–4.6Zr. Biomaterials 24(16):2673–2683

Sander B, Raabe D (2008) Texture inhomogeneity in a Ti–Nb–based β–titanium alloy after warm rolling and recrystallization. Mater Sci Eng, A 479(1–2):236–247

Valiev RZ, Langdon TG (2006) Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog Mater Sci 51(7):881–981

Zhilyaev AP, Langdon TG (2008) Using high-pressure torsion for metal processing: fundamentals and applications. Prog Mater Sci 53(6):893–979

Lewandowska M, Kurzydlowski K (2008) Recent development in grain refinement by hydrostatic extrusion. J Mater Sci 43(23–24):7299–7306

Li Z, Fu L, Fu B, Shan A (2012) Effects of annealing on microstructure and mechanical properties of nano-grained titanium produced by combination of asymmetric and symmetric rolling. Mater Sci Eng, A 558:309–318

Segal VM (1995) Materials processing by simple shear. Mater Sci Eng, A 197(2):157–164

Ungár T (2001) Dislocation densities, arrangements and character from X-ray diffraction experiments. Mater Sci Eng, A 309–310:14–22

Ungar T, Dragomir I, Revesz A, Borbely A (1999) The contrast factors of dislocations in cubic crystals: the dislocation model of strain anisotropy in practice. J Appl Crystallogr 32(5):992–1002

Ungar T, Gubicza J, Ribarik G, Borbely A (2001) Crystallite size distribution and dislocation structure determined by diffraction profile analysis: principles and practical application to cubic and hexagonal crystals. J Appl Crystallogr 34(3):298–310

Lanson B (1997) Decomposition of experimental X-ray diffraction patterns (profile fitting): a convenient way to study clay minerals. Clays Clay Miner 45(2):132–146

Karasevskaya OP, Ivasishin OM, Semiatin SL, Matviychuk YV (2003) Deformation behavior of beta–titanium alloys. Mater Sci Eng, A 354(1–2):121–132

Abdel-Hady M, Hinoshita K, Morinaga M (2006) General approach to phase stability and elastic properties of β-type Ti–alloys using electronic parameters. Scr Mater 55(5):477–480

Grosdidier T, Combres Y, Gautier E, Philippe MJ (2000) Effect of microstructure variations on the formation of deformation-induced martensite and associated tensile properties in a β metastable Ti alloy. Metall Mater Trans A 31(4):1095–1106

Banerjee S, Mukhopadhyay P (2007) Phase transformations: examples from titanium and zirconium alloys. Elsevier, Oxford

Souza SA, Manicardi RB, Ferrandini PL, Afonso CRM, Ramirez AJ, Caram R (2010) Effect of the addition of Ta on microstructure and properties of Ti–Nb alloys. J Alloy Compd 504(2):330–340

Kim HY, Ikehara Y, Kim JI, Hosoda H, Miyazaki S (2006) Martensitic transformation, shape memory effect and superelasticity of Ti–Nb binary alloys. Acta Mater 54(9):2419–2429

Levitas VI, Idesman AV, Olson GB (1998) Continuum modeling of strain-induced martensitic transformation at shear-band intersections. Acta Mater 47(1):219–233

Hanada S, Ozeki M, Izumi O (1985) Deformation characteristics in Β phase Ti–Nb alloys. MTA 16(5):789–795

Zherebtsov SV, Dyakonov GS, Salem AA, Malysheva SP, Salishchev GA, Semiatin SL (2011) Evolution of grain and subgrain structure during cold rolling of commercial-purity titanium. Mater Sci Eng, A 528(9):3474–3479

Grosdidier T, Philippe MJ (2000) Deformation induced martensite and superelasticity in a β–metastable titanium alloy. Mater Sci Eng, A 291(1–2):218–223

Hao YL, Yang R, Niinomi M, Kuroda D, Zhou YL, Fukunaga K, Suzuki A (2002) Young’s modulus and mechanical properties of Ti–29Nb–13Ta–4.6Zr in relation to α” martensite. Metall Mater Trans A. 33 (10):3137–3144

Hida M, Sukedai E, Henmi C, Sakaue K, Terauchi H (1982) Stress induced products and ductility due to lattice instability of β phase single crystal of Ti-Mo alloys. Acta Metall 30(8):1471–1479

Valiev RZ, Alexandrov IV, Zhu YT, Lowe TC (2002) Paradox of strength and ductility in metals processed by severe plastic deformation. J Mater Res 17(01):5–8

Duan X, Sheppard T (2003) Simulation and control of microstructure evolution during hot extrusion of hard aluminium alloys. Mater Sci Eng, A 351(1–2):282–292

Califano V, Champagnon B, Fanelli E, Pernice P, Sigaev V, Zakharkin D, Sakharov V, Baskov P (2004) Anisotropy in extruded lanthanum borogermanate glasses? Structural study by Raman spectroscopy. Philos Mag 84(13–16):1639–1644

Xu C, Langdon T (2007) The development of hardness homogeneity in aluminum and an aluminum alloy processed by ECAP. J Mater Sci 42(5):1542–1550

Suś-Ryszkowska M, Wejrzanowski T, Pakieła Z, Kurzydłowski KJ (2004) Microstructure of ECAP severely deformed iron and its mechanical properties. Mater Sci Eng, A 369(1–2):151–156

Xu C, Furukawa M, Horita Z, Langdon TG (2005) The evolution of homogeneity and grain refinement during equal-channel angular pressing: a model for grain refinement in ECAP. Mater Sci Eng, A 398(1–2):66–76

DeLo DP, Semiatin SL (1999) Finite-element modeling of nonisothermal equal-channel angular extrusion. Metall Mater Trans A 30(5):1391–1402

Yamaguchi D, Horita Z, Nemoto M, Langdon TG (1999) Significance of adiabatic heating in equal-channel angular pressing. Scr Mater 41(8):791–796

Bailey JE (1963) The dislocation density, flow stress and stored energy in deformed polycrystalline copper. Philos Mag 8(86):223–236

Acknowledgements

The financial support from the US National Science Foundation (NSF DMR-1210437) is gratefully appreciated. For RZV, this project was partially supported by the Russian Federal Ministry for Education and Science (Contract No. 14.B25.31.0017). The author (ZL) would like to thank the financial support from the China Scholarship Council (No. 201306230030).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, Z., Zheng, B., Wang, Y. et al. Ultrafine-grained Ti–Nb–Ta–Zr alloy produced by ECAP at room temperature. J Mater Sci 49, 6656–6666 (2014). https://doi.org/10.1007/s10853-014-8337-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8337-6