Abstract

We present effects of intrinsic twist and material orthotropy on extension–twist–inflation coupling in circular tubes about their stress-free state. Simple analytical expressions for coupling stiffnesses corresponding to extension–twist, twist–inflation and extension–inflation couplings are obtained. We show that the sign of the extension–twist coupling stiffness, which governs initial overwinding/unwinding in tubes during their extension, is not just dependent on the tube’s intrinsic twist but also on two other parameters: ratio of the Young’s moduli in the lateral surface of orthotropic tube and the excess of the Poisson’s ratio from an isotropy condition. By tuning these two parameters, one can generate the counter-intuitive overwinding as reported earlier in the case of DNA. Similarly, we show that even with positive Poisson’s ratio, an intrinsically twisted tube could inflate on being stretched. We also present a scheme to obtain all the relevant stiffnesses of chiral single-walled carbon nanotubes from a “one-atom unit cell” calculation. These stiffnesses, when plotted vs. the nanotube’s chirality, exhibit interesting periodicity which has its origin in the 6-fold symmetry of graphene. This trend is captured in the continuum model for a nanotube when it is assumed to be comprised of three families of parallel fibers on its lateral surface.

Similar content being viewed by others

Notes

We define “inflation strain” as the ratio of change in inner radius of a tube to its inner radius in the relaxed state.

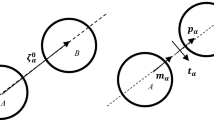

Due to the imposed twist \(\kappa \), the third set of principal material lines (green lines in Fig. 1) get twisted by (\(\kappa_{0}+\kappa \)) in the deformed state.

From now on, we will use \(\hat{()}\) to denote quantities corresponding to special Cosserat rod theory whereas \(\tilde{()}\) will be used to denote quantities for the general theory of Cosserat rods.

In the case where inflation is prescribed (for \(\tilde{\varPhi }\)), we have kinematic boundary condition at the inner radius, i.e., \(b(r_{1})=b_{1}\).

The linear terms of \(W\) in strains vanish due to the expansion of \(W\) being done about the stress-free state.

The physical meanings of (\(\hat{f}, \hat{l}\)) in (8a)–(8d) are the in-plane and out-of-plane warping solutions respectively for pure extension of a tube keeping twist zero while (\(\tilde{f}, \tilde{l}\)) denote the two warping solutions for pure extension keeping both twist and inflation strain zero. Similarly, (\(\hat{g},\hat{m}\)) denote the warping solutions for pure torsion of a tube keeping axial strain zero while (\(\tilde{g},\tilde{m}\)) denote the same but keeping both axial strain and inflation strain zero. Finally, (\(\tilde{h},\tilde{n}\)) denote warping solutions for inflation of a tube keeping both axial strain and twist zero.

The bold symbol \(\boldsymbol{\epsilon }\) denoting strain matrix should not be confused with the scalar \(\epsilon \) denoting axial strain.

For general material models, the linear stress-strain relation can be obtained by first Taylor-expanding the nonlinear hyperelastic strain energy density \(W\) up to quadratic order in strains. The derivative of the quadratic expansion with respect to strain will then yield the expression for stress.

The physical meaning of non-vanishing \(\tilde{\sigma }_{rr}(r_{1})\) is the external pressure required at the inner radius to impose the inflation strain \(b_{1}\).

Using \(\sigma_{rr}(r_{1})=0\) directly to obtain \(\hat{b}(r_{1})\) does not work since the expression for \(\sigma_{rr}(r_{1})\) contains both \(\hat{b}(r_{1})\) and the derivative \(\hat{b}^{\prime }(r_{1})\) as unknowns.

Two new parameters \(\lambda \) and \(\nu_{\text{iso}}\) are introduced in Table 1 replacing \((E_{2},G_{23})\) such that \(\lambda = E_{2}/E_{3}\) and \(G_{23}=\frac{E_{3}}{2(1+\nu_{\text{iso}})}\). The term \(\nu_{\text{iso}}\) derives its name from the fact that it would be the actual Poisson’s ratio if the material were isotropic. The Poisson’s ratio \(\nu_{32}\) has also been renamed as \(\nu \).

For finite strain parameters, the cross-sectional energy \(\tilde{\varPhi }\) becomes proportional to cross-sectional area (or proportional to thickness) in thin-tube limit and so does its derivative with respect to non-dimensional strain parameters.

We have adjusted the upper limit of \((\nu -\nu_{\text{iso}})\) in Fig. 4 so that it satisfies the following inequality constraint: \((1-\lambda \nu^{2})>0\Rightarrow -\frac{1}{\sqrt{ \lambda }}<\nu <\frac{1}{\sqrt{\lambda }}\). Also, \(E_{3}>0,G_{23}>0 \Rightarrow -1<\nu_{\text{iso}}<\infty \). Hence, \(-\infty <(\nu -\nu_{\text{iso}})<1+\frac{1}{\sqrt{ \lambda }}\).

Along these three fiber systems, there is a continuation of inter-atomic interactions.

References

Aggeli, A., Nyrkova, I.A., Bell, M., Harding, R., Carrick, L., McLeish, T.C.B., Semenov, A.N., Boden, N.: Hierarchical self-assembly of chiral rod-like molecules as a model for peptide \(\beta \)-sheet tapes, ribbons, fibrils, and fibers. Proc. Natl. Acad. Sci. USA 98, 11857–11862 (2001)

Antman, S.S., Carbone, E.R.: Shear and necking instabilities in nonlinear elasticity. J. Elast. 7, 125–151 (1977)

Antman, S.S.: Nonlinear Problems of Elasticity. Springer, New York (1995)

Audoly, B., Hutchinson, J.W.: Analysis of necking based on a one-dimensional model. J. Mech. Phys. Solids 97, 68–91 (2016)

Bertoldi, K., Reis, P.M., Willshaw, S., Mullin, T.: Negative Poisson’s ratio behavior induced by an elastic instability. Adv. Mater. 22, 361–366 (2010)

Bozec, L., van der Heijden, G., Horton, M.: Collagen fibrils: nanoscale ropes. Biophys. J. 92, 70–75 (2007)

Brenner, D.W.: Empirical potential for hydrocarbons for use in simulating the chemical vapor deposition of diamond films. Phys. Rev. B 42, 9458 (1990)

Cai, W., Fong, W., Elsen, E., Weinberger, C.R.: Torsion and bending periodic boundary conditions for modeling the intrinsic strength of nanowires. J. Mech. Phys. Solids 56, 3242–3258 (2008)

Chandraseker, K., Mukherjee, S.: Coupling of extension and twist in single-walled carbon nanotubes. J. Appl. Mech. 73, 315–326 (2006)

Chang, T.: A molecular based anisotropic shell model for single-walled carbon nanotubes. J. Mech. Phys. Solids 58, 1422–1433 (2010)

Coleman, B.D.: Necking and drawing in polymeric fibers under tension. Arch. Ration. Mech. Anal. 83, 115 (1983)

Durickovic, B., Goriely, A., Maddocks, J.H.: Twist and stretch of helices explained via the Kirchhoff–Love rod model of elastic filaments. Phys. Rev. Lett. 111, 108103 (2013)

Gent, A.N., Rivlin, R.S.: Experiments on the mechanics of rubber II: the torsion, inflation and extension of a tube. Proc. Phys. Soc. B 65, 487–501 (1952)

Gore, J., Bryant, Z., Nöllmann, M., Le, M.U., Cozzarelli, N.R., Bustamante, C.: DNA overwinds when stretched. Nature 442, 836–839 (2006)

Gupta, P., Kumar, A.: Effect of material nonlinearity on spatial buckling of nanorods and nanotubes. J. Elast. 126, 155–171 (2017)

Goriely, A., Tabor, M.: Rotation, inversion and perversion in anisotropic elastic cylinderical tubes and membranes. Proc. R. Soc. A, Math. Phys. Eng. Sci. 469, 20130011 (2013)

Green, A.E., Laws, N.: A general theory of rods. Proc. R. Soc. Lond. Ser. A, Math. Phys. Sci. 293, 145–155 (1966)

Gross, P., Laurens, N., Oddershede, L.B., Bockelmann, U., Peterman, E.J., Wuite, G.J.: Quantifying how DNA stretches, melts and changes twist under tension. Nat. Phys. 7, 731–736 (2011)

Healey, T.J.: Material symmetry and chirality in nonlinearly elastic rods. Math. Mech. Solids 7, 405–420 (2002)

Holzapfel, G.A., Ogden, R.W.: Constitutive modeling of arteries. Proc. R. Soc. A 466, 1551–1597 (2010)

Horgan, C.O., Murphy, J.G.: Extension or compression induced twisting in fiber-reinforced nonlinearly elastic circular cylinders. J. Elast. 125, 73–85 (2016)

Iesan, D., Quintanilla, R.: On the deformation of inhomogeneous orthotropic elastic cylinders. Eur. J. Mech. A, Solids 26, 999–1015 (2007)

Iesan, D.: Chiral effects in uniformly loaded rods. J. Mech. Phys. Solids 58, 1272–1285 (2010)

Itskov, M., Aksel, N.: A class of orthotropic and transversely isotropic hyperelastic constitutive models based on a polyconvex strain energy function. Int. J. Solids Struct. 41, 3833–3848 (2004)

James, R.D.: Objective structures. J. Mech. Phys. Solids 54, 2354–2390 (2006)

Kumar, A., Healey, T.J.: A generalized computational approach to stability of static equilibria of nonlinearly elastic rods in the presence of constraints. Comput. Methods Appl. Mech. Eng. 199, 1805–1815 (2010)

Kumar, A., Mukherjee, S.: A geometrically exact rod model including in-plane cross-sectional deformation. J. Appl. Mech. 78, 011010 (2011)

Kumar, A., Mukherjee, S., Paci, J.T., Chandraseker, K., Schatz, G.C.: A rod model for three dimensional deformations of single-walled carbon nanotubes. Int. J. Solids Struct. 48, 2849–2858 (2011)

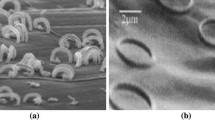

Kumar, A., Kumar, S., Gupta, P.: A helical Cauchy–Born rule for special Cosserat rod modeling of nano and continuum rods. J. Elast. 124, 81–106 (2016)

Kurbatova, N.V., Ustinov, Y.A.: Saint-Venant problem for solids with helical anisotropy. Contin. Mech. Thermodyn. 28, 465–476 (2016)

Lakes, R.S., Benedict, R.L.: Noncentrosymmetry in micropolar elasticity. Int. J. Eng. Sci. 20, 1161–1167 (1982)

Lakes, R.S.: Foam structures with negative Poisson’s ratio. Science 235, 1038–1040 (1987)

Lionnet, T., Joubaud, S., Lavery, R., Bensimon, D., Croquette, V.: Wringing out DNA. Phys. Rev. Lett. 96, 178102 (2006)

Maultzsch, J., Telg, H., Reich, S., Thomsen, C.: Radial breathing mode of single-walled carbon nanotubes: optical transition energies and chiral-index assignment. Phys. Rev. B 72, 205438 (2005)

Merodio, J., Ogden, R.W.: Extension, inflation and torsion of a residually stressed circular cylinderical tube. Contin. Mech. Thermodyn. 28, 157–174 (2016)

Ogden, R.W., Chadwick, P.: On the deformation of solid and tubular cylinders of incompressible isotropic elastic materials. J. Mech. Phys. Solids 20, 77–90 (1972)

Poynting, J.H.: On pressure perpendicular to the shear planes in finite pure shears, and on the lengthening of loaded wires when twisted. Proc. R. Soc. Lond. Ser. A, Math. Phys. Sci. 82, 546–559 (1909)

Raamachandran, J., Jayavenkateshwaran, K.: Modeling of stents exhibiting negative Poisson’s ratio effect. Comput. Methods Biomech. Biomed. Eng. 10, 245–255 (2007)

Ru, Q.C.: Chirality-dependent mechanical behavior of carbon nanotubes based on an anisotropic elastic shell model. Math. Mech. Solids 14, 88–101 (2009)

Upamanyu, M., Wang, H.L., Liang, H.Y., Mahajan, R.: Strain dependent twist stretch elasticity in chiral filaments. J. R. Soc. Interface 20, 303–310 (2008)

Wang, M.D., Yin, H., Landick, R., Gelles, J., Block, S.M.: Stretching DNA with optical tweezers. Biophys. J. 72, 1335–1346 (1997)

Acknowledgements

We thank Anuj Arora, Akash Verma and Pranjal Singh for their valuable suggestions during the course of this work. The funding from SERB, DST (YSS/2014/000023) and partial support from CSIR, India (sanction # 22(0709)/16/EMR-II) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A: Saint-Venant’s Orthotropic Constitutive Relations

We show below the expression for Saint-Venant’s orthotropic constitutive relations as presented in Itskov and Aksel [24]:

For small deformations, \(\mathit{tr}(\mathbf{E}\mathbf{L}_{i})\) denotes infinitesimal normal strain (\(\epsilon_{ii}^{\ast }\)) along the \(i\)th principal direction while \(\mathit{tr}(\mathbf{E}\mathbf{L}_{i}\mathbf{E} \mathbf{L}_{j})\) denotes the square of shear strain (\(\epsilon_{ij} ^{\ast }\)) in the plane formed by \((i,j)\) principal material directions. Accordingly, the Cauchy stress vs. the infinitesimal strain relation in the coordinate system of principal material directions appear as

The meaning of other terms in (44) and (45) are as follows:

The orthotropic material constants must be such that they lead to positive definiteness of the quadratic form \(W\) in (44) with respect to infinitesimal strains. Accordingly, the orthotropic constants must satisfy the following inequality constraints:

In case of thin tubes, only four constants (\(E_{2},E_{3},G_{23},\nu _{32}\)) are relevant. Accordingly, only the following constraints need to be satisfied:

Appendix B: System of ODEs and Boundary Conditions for Linearized In-Plane Warping Functions

We now present the system of ODEs and boundary conditions for linearized in-plane warping functions. We first present them in Table 4 for the case when no inflation strain is imposed. These linear ODEs are obtained by substituting the Taylor-expanded warping function (8a) in (12a) and then collecting the coefficients of \(\epsilon \) and \(\kappa \) separately.

The system of ODEs and boundary conditions for the case in which inflation strain is also imposed are obtained similarly. Here, the kinematic boundary condition at inner radius implies:

The ODEs and the above boundary conditions are presented in Table 5 for readers’ convenience.

Appendix C: Thin Tube Limits

Upon Taylor-expanding the radial stress \(\sigma_{rr}\) about inner radius, we obtain:

As both (\(\sigma_{rr}(r_{1}),\sigma_{rr}(r_{2})\)) vanish due to traction free boundary conditions for special Cosserat rod model, evaluating (50) at \(r=r_{2}\) leads to

In the thin tube limit (\(T\to 0\)), we then obtain \(\frac{\mathrm{d} \sigma_{rr}}{\mathrm{d}r}(r_{1})=0\). This results in (17), i.e.,

In case inflation strain is also prescribed, \(\sigma_{rr}(r_{1}) \ne 0\) but \(\sigma_{rr}(r_{2})=0\). Substituting them in (50) for \(r=r_{2}\), dividing by thickness and further taking thin-tube limit, we obtain (22), i.e.,

Appendix D: Stiffness Expressions for Isotropic Thick Tubes

The stiffness expressions simplify a lot here due to isotropy. In case no inflation is imposed, we have:

Here, \(A\) and \(J\) are the cross-sectional area and the polar moment of area respectively. The stiffnesses for the case when inflation is also imposed are presented in Table 6. An interesting observation to note here is that the extensional and inflation stiffnesses are not the same although they match in thin tube limit. We can also note that the ratio of \(\tilde{\mathcal{G}}\) and \(\tilde{\mathcal{I}}\) is \(\nu \) implying that an isotropic tube always exhibits Poisson effect as dictated by its Poisson’s ratio.

Rights and permissions

About this article

Cite this article

Singh, R., Kumar, S. & Kumar, A. Effect of Intrinsic Twist and Orthotropy on Extension–Twist–Inflation Coupling in Compressible Circular Tubes. J Elast 128, 175–201 (2017). https://doi.org/10.1007/s10659-017-9623-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10659-017-9623-8