Abstract

The aim of this work was to obtain an inorganic oxide system containing silica and magnesium oxide, and characterized by specific physicochemical properties, in particular well-defined adsorption parameters. The preparation process was carried out according to a co-precipitation method using solutions of sodium silicate and selected inorganic magnesium salt. The oxide system obtained (MgO·SiO2) was used as a support (adsorbent) of nickel(II) ions, whose precursors were model solutions of nitrates. The effectiveness of the adsorption process was evaluated using many different analytical techniques, including atomic absorption spectroscopy, energy dispersive X-ray spectroscopy and equivalent point titration. Moreover the stability of adsorbent/adsorbate bonding was estimated. The oxide systems—adsorbents—used in the process were also analyzed according to their physicochemical properties, especially changes in adsorption parameters. The last part of the study involved evaluation of the kinetics of the adsorption process depending on time and the pH of the reaction system.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

1 Introduction

Research work of great importance for scientific advancement, especially in chemical technology, materials science and broadly defined environmental protection, concerns the formation of a new generation of hybrid oxide systems. This substantial research area concerns problems relating to the synthesis of functional inorganic oxides and hybrids, which are characterized by new, defined physicochemical and useful properties. The need for new materials is especially urgent as regards their applications as adsorbents, being alternatives to natural substances. The physicochemical properties of oxide systems depend mainly on the method of their synthesis (Modrzejewska-Sikorska et al. 2010).

Co-precipitated oxides (e.g. synthetic silicates) have been used for a long time in many applications, including in the most advanced technologies in electronics, biochemistry and petrochemistry (Kumar 2009). The most beneficial property of the silicates used in the chemical and pharmaceutical industries and agriculture is their adsorption capacity and the possibility of their modification (physical and chemical). They have been used in wastewater and mineral oils purification (Johnson et al. 2004; Amin et al. 2011).

Many industries generate a large amount of waste water containing heavy metals. These compounds are toxic or even carcinogenic. The increasing problem of inorganic pollution of water, mainly with heavy metals, has caused great interest in technological methods enabling the removal of these compounds. Commonly used methods are precipitation (Lewis 2010), membrane techniques (Mungray et al. 2012), ion exchange (Maturana et al. 2011), extraction (Regel-Rosocka et al. 2006), and adsorption (Chen et al. 2012); see Fig. 1.

Adsorption is considered one of the most efficient and economical methods for removing heavy metal ions from aqueous solutions. It is a very flexible process, both in design and implementation. Another advantage is the fact that the adsorption may be reversible, through desorption, which allows the regeneration of the adsorbents used in the process.

In the last few years there has been increasing interest at many research centers in matters relating to adsorbents of natural origin. The objective is to obtain materials which are economically advantageous and efficient in the removal of metal ions from aqueous solutions. Natural adsorbents are compounds that occur in the environment. In particular, biomass has very favorable adsorption properties. The most common natural adsorbents, or material from which they are produced, used in the process of removing metal ions include activated carbon (coconut shell), tree bark, lignin, shellfish shells, cotton, zeolites, fern, and compounds contained in a number of minerals and microorganisms (bacteria, fungi and yeast) (Mendoza-Barrón et al. 2011; Moreno-Piraján et al. 2011; Dhir and Srivastava 2011; Fosso-Kankeu et al. 2011; Sheng et al. 2009).

At a time of continual development of technology, synthetic adsorbents also used in the removal of heavy metal ions from aqueous solutions are gaining increasing popularity (Tofighy and Mohammadi 2011; Gandhi and Meenakshi 2012; Majdan et al. 2010). Sorbents prepared in the laboratory can display similar or even better physicochemical properties than their natural counterparts. Synthetic adsorbents include magnesium oxide, aluminum oxide, iron(II) and (III) oxides, titanium dioxide, and composites, which include chitin, chitosan and various oxide systems (Klapiszewski et al. 2012).

Adsorption of nickel(II) from model solutions onto different adsorbents is carefully studied by many researchers. One of the effective adsorbents of nickel is lignin—natural waste in cellulose processing (Betancur et al. 2009). Efficiency of nickel(II) ions removal from an aqueous solution in the case of using normal lignin was 90 %. However, demineralization of this biosorbent improved the effectiveness of the process—almost complete removal of nickel ions(II) was achieved. In the next article (Li et al. 2008), chitosan/TiO2 hybrid system was proposed as new adsorbent. Titanium dioxide was immobilized on chitosan matrix. As in the case of lignin, chitosan-TiO2 system was effective in the removal of nickel ions(II) from aqueous solutions (process yield was 90 %). Similar results were obtained during adsorption of nickel onto chitosan/silica hybrid adsorbent (Singhon et al. 2012).

Argun in his study (Argun 2008), in order to remove nickel ions from a solution, used clinoptilolite as adsorbent. The results confirmed that the process conditions such as pH, the amount of clinoptilolite and the amount of nickel in the initial solution, have a large effect on the metal removal efficiency. Engates and others (Engates and Shipley 2011) performed studies concerning adsorption of nickel(II), cadmium(II) and lead(II) ions onto TiO2 nanoparticles. The results confirmed a significant adsorption capacity of titanium dioxide nanoparticles.

There are numerous literature reports on studies intended to determine optimum conditions for the adsorption of selected heavy metal ions (Benguella and Benaissa 2002; Onundi et al. 2011). Among the fundamental process parameters that determine the kinetics and efficiency of the adsorption process are temperature, time, pH, concentration of reactants and the time of their contact (Padilla-Ortega et al. 2011).

Due to the growing interest in alternative adsorbents, so-called low-cost adsorbents, an attempt was made to achieve nickel(II) ion adsorption onto a new generation of inorganic oxide system obtained by precipitation, characterized especially by well-defined adsorption properties.

2 Experimental section

2.1 Materials

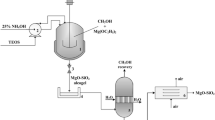

The synthetic inorganic oxide system was obtained in a process of precipitation from aqueous solutions of sodium silicate and magnesium sulfate, as described earlier (Ciesielczyk et al. 2011); see Fig. 2. As a result of this process, an oxide system characterized by micrometer-sized particles, amorphous structure and a relatively large BET surface area was obtained. In the adsorption process, together with the inorganic oxide, a model solution of nickel ions–nickel(II) nitrate—was used (Ni(NO3)2·6H2O, POCh SA), in initial concentrations of 0.05, 0.10, 0.25, 0.50, 0.75 and 1.00 g/dm3.

2.2 Adsorption process

The adsorption process was carried out with varying pH of the system. The aim was to determine the influence of this parameter on the efficiency of nickel(II) ion adsorption using its model aqueous solutions. The process was performed for each concentration of nickel(II) nitrate by manipulating the pH (2, 4, 6, 7.5, 9, 11). Changes in pH towards alkaline or acidic were achieved using 0.1 M sodium hydroxide and nitric acid. During the adsorption process, the effect of oxidation of Ni(II) to Ni(III) wasn’t analyzed, including the fact that the +3 degree of oxidation of nickel is very unstable.

The prepared nickel(II) salt solutions at different concentrations (250 cm3 each) were placed in conical flasks. To the adsorbate solution adsorbent was added in a quantity of 7.5 g. Then, to obtained the desired pH, as monitored using a pH meter (CP-401, Elmetron), sodium hydroxide or nitric acid solutions in a concentration of 0.1 M were added; see Fig. 3. After stabilization of pH at the desired value, the system was stirred using a magnetic stirrer (Ika Werke GmbH) for 1 h. After 1 h the mixture was filtered under reduced pressure. The resulting solid was dried for 2 h at 105 °C. Both the resulting adsorbent and the filtrate obtained at each step of the adsorption process were subjected to further analysis.

In order to determine the stability of bonds between the adsorbate and the adsorbent, and to determine the effectiveness of the removal of nickel ions(II) from the surface of the adsorbent (desorption), elution tests with water were performed.

One gram of the solid obtained after the adsorption process was placed in a flask filled with 30 cm3 of distilled water. The resulting mixture was stirred using a magnetic stirrer (IKA Werke GmbH) for 1 h. The obtained dispersion was filtered under reduced pressure. The filtrate was subjected to further testing to determine the quantity of unadsorbed nickel(II) ions.

2.3 Efficiency of adsorption

2.3.1 Equivalent point titration (EQP)

EQP titration analysis enabled qualitative evaluation of the quantity of nickel(II) ions in the filtrate after the adsorption process and the elution tests. The complexometric method was used for this analysis. Disodium edentate was used as a complexing agent. The analysis was performed using a Mettler Toledo T50 titrator equipped with a DP5TM phototrode.

In order to perform the measurement, 1 cm3 of the filtrate obtained after the adsorption was diluted with 40 cm3 of distilled water. Then 1 cm3 of ammoniacal buffer and 4 drops of 2 M sodium hydroxide solution were added. Finally 1–2 mg of the indicator murexide was introduced.

The yellow (straw) sample, prepared in this way, was titrated using 0.005 M EDTA until the color changed to violet. The measurement was performed with an accuracy of ±0.005 mol/dm3.

2.3.2 Atomic absorption spectroscopy (AAS)

AAS analysis was performed additionally to determine the quantity of nickel(II) ions present in the filtrate after the adsorption process and elution tests. This is one of the most accurate methods for quantitative analysis. This study was carried out using a Z-8200 spectrometer (Hitahchi). Before analyzing the samples, a calibration curve was prepared to enable the calculation of nickel(II) ion concentration in the filtrate. The measurements were performed with an accuracy of ±0.1 mg/dm3.

2.4 Evaluation of physicochemical properties of adsorbent before and after adsorption

The dispersive characteristic of the oxide adsorbent was determined using a Mastersizer 2000 apparatus made by Malvern Instruments Ltd., operating using the laser diffraction method and measuring particles of sizes from 0.2 to 2,000 μm. The resolution of determination of the effective particle diameter was 0.1 μm. Measurements of particle size were repeated at least ten times for each sample. The morphology and microstructure of the adsorbent obtained was analyzed using a Zeiss EVO40 scanning electron microscope. The observations permitted evaluation of the dispersion degree, the structure of particles and their tendency towards aggregation or agglomeration. The specific surface area ABET (BET method) was calculated based on data measured by low-temperature adsorption of nitrogen. The isotherms of nitrogen adsorption/desorption were measured at 77 K using an ASAP 2020 apparatus made by Micromeritics Instrument Co. With regard to the high accuracy of the instrument used (±0.0001 m2/g) the surface area values were rounded up to whole numbers, and the mean pore size (Sp) and total pore volume (Vp) calculated using the BJH method were rounded to one and two decimal places respectively. The MgO·SiO2 oxide adsorbent was also subjected to crystal structure determination using the WAXS method. X-ray diffraction measurements were performed using Cu Kα radiation and a fixed power source (30 kV, 15 mA). The samples were scanned at a rate of 0.04° over the range 3–60°. Moreover the surface composition of oxide adsorbents was analyzed by energy dispersive X-ray spectroscopy (EDS). Using a Zetasizer Nano ZS (operating on the non-invasive back scattering light method) it was also possible to measure the electrophoretic mobility using laser Doppler velocimetry (LDV), and indirectly the zeta potential (Zetasizer Nano ZS software provides the ability to calculate electrophoretic mobility values into the zeta potential based on the Henry equation). The electrokinetic potential was measured over the whole pH range in the presence of 0.001 M NaCl electrolyte, which made it possible to determine the electrokinetic curves.

Due to the color change in the adsorbent structure after the process, colorimetric analysis was performed using a colorimeter (Specbos 4000, JETI Technische Instrumente GmbH). Daylight (D65) was used as a standard light source. The instrument evaluated the color in terms of the CIE L*a*b* color space system. In this color space, L* represents the brightness, and a* and b* are appropriate color coordinates.

3 Results and discussion

3.1 Adsorbent characteristic

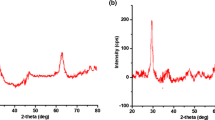

In the first stage of the study, the physicochemical characteristic of the adsorbent—a precipitated MgO·SiO2 oxide system—was investigated. Evaluation of dispersive properties showed that 90 % of the synthetic adsorbent particles have diameters less than 62.3 μm, and 10 % of the particles have diameters less than 3.9 μm. The dominant particle diameter of the inorganic oxide is 36.8 μm. The nature of the adsorbent dispersion presented in the particle size distribution (Fig. 4a) and in Table 1 is confirmed by the SEM photograph (Fig. 4b), where particles of varying size and also irregular shape can be seen. Thus analysis of the chemical composition of the oxide adsorbent (Table 1) proved the presence of two dominant components in its structure: SiO2 (54.1 %) and MgO (20.4 %). The presence of other components such as CaO, Na2O and K2O is related with the substrates used in the process of precipitation of the adsorbent and results from incomplete washing after precipitation. The amounts of these components are so small that they do not affect the physicochemical properties of the product. In addition, the structure of the adsorbent contains a certain amount of moisture (22.8 %). However this amount can be reduced by the selection of an appropriate heat treatment technique (Ciesielczyk and Jesionowski 2011), which directly determines the surface activity, translating into a number of reactive silanol and magnesil groups (≡Si–OH and –Mg–OH). Due to the preparation of the synthetic oxide adsorbent in the laboratory, it was necessary to determine its crystal structure, which in the case of similar oxide systems such as TiO2·SiO2 plays an important role in their applications (Siwińska-Stefańska et al. 2012). The results showed that the resulting oxide system has a completely amorphous structure (Fig. 5). Using the synthetic MgO·SiO2 oxide system as a selective adsorbent, it was also necessary to determine its adsorption properties. Therefore, the nitrogen adsorption/desorption isotherm was plotted (Fig. 6a). It was found that above a relative pressure value (p/p 0) of 0.8 a rapid increase in the amount of adsorbed nitrogen occurs, up to its maximum value of 310 cm3/g for the relative pressure p/p 0 = 1. The synthetic oxide adsorbent is surface area of 427 m2/g, pore volume Vp = 0.49 cm3/g and pore diameter Sp = 4.5 nm. Both the nature of the isotherm and the pore size distribution (Fig. 6b) indicate the mesoporous structure of the adsorbent.

3.2 Efficiency of adsorption

Figure 7 presents the efficiencies of adsorption obtained during EQP and AAS analysis. The presented results of titration analysis (Fig. 7a)—in this case only a qualitative analysis—confirm the effectiveness of adsorption of the nickel(II) ions onto inorganic oxide adsorbent, especially when the process was carried out at alkaline pH (pH > 8). It is worth noting that for a reaction system with pH < 8, the higher the initial concentration of the adsorbate, the higher the efficiency of adsorption. Thus for the highest analyzed pH, it turned out that the yield obtained was close to 100 %, regardless of the initial concentration of the model nickel salt solution. Confirmation of the results of the research is given by the experimental data presented in Fig. 7b, obtained from the AAS analysis. AAS analysis is commonly used particularly in quantitative analysis for the determination of metal ions in aqueous solutions. The highest yield was obtained adsorbing Ni(II) ions from model solutions of Ni(NO3)2 at pH = 11. The efficiencies were 97.6, 98.4 and 99.2 % for nickel salt solutions at concentrations of 0.25, 0.50 and 1.00 g/dm3 respectively. To evaluate the stability of Ni(II)/adsorbent bonding, elution tests with water were performed, which clearly confirmed the insignificant percentage removal of nickel from the surface of the adsorbent. Carrying out a process of adsorption of nickel ions on the TiO2·SiO2 oxide system, authors have obtained yields of 30–35 % at pH = 2, and an efficiency of close to 100 % with an increase in the basicity (pH = 8) of the reaction system (Ismail et al. 2008). A research group studying the adsorption of this metal on kaolinite (Jiang et al. 2010) confirmed an analogous efficiencies of nickel removal from aqueous solutions by its adsorption.

In order to confirm the efficiency of adsorption of nickel(II) ions onto synthetic oxide adsorbent, the energy dispersive X-Ray diffraction analysis (EDS) was carried out for selected adsorbents used in the study. The results are presented in Tables 2 and 3. The experimental data show the contribution of each element (the percentage mass and atomic contribution) present on the surface of the synthetic MgO·SiO2 adsorbent.

The results of the EDS analysis of the initial adsorbent used in the process of Ni(II) adsorption are given in Table 3. The presence in the sample of synthetic adsorbent elements such as magnesium, silicon, and oxygen is directly related to its chemical formula. On the other hand, contributions of sodium, potassium and calcium are related to the method of its preparation, including the substrates necessary for its precipitation, in particular sodium silicate solution.

Analysis of the surface composition of the adsorbents used to remove Ni(II) ions from nickel(II) nitrate, with solution concentrations of 0.5 and 1.0 g/dm3 depending on the pH of the reaction system (Table 3), confirmed that the content of nickel in the structure of the adsorbent was lowest in the case of acidic pH (pH = 2). Nickel content of 0.42 % by mass was observed following an adsorption process using nickel(II) nitrate solution in initial concentration 0.5 g/dm3, and a content of 0.75 % by mass was attained using adsorbate solution in a concentration of 1 g/dm3. It is worth noting that these results are directly correlated with the adsorption efficiencies calculated based on previous analyzes.

When the process of adsorption was realized at pH = 7.5, significant amounts of nickel were observed in the structure of the adsorbent: 0.49 and 0.95 % by mass for adsorbate solutions in concentrations of 0.50 and 1.00 g/dm3, respectively. Adsorption in an alkaline system (pH = 11) produced the highest concentration of nickel in the structure of the adsorbent. After the process realized with nickel salt solution in initial concentration 0.50 g/dm3 the nickel content was 0.79 % by mass, and for nickel(II) nitrate solution in initial concentration 1 g/dm3 the content was 1.33 %. These values are the highest among all those obtained in analysis of the adsorbents used. This agrees with the efficiency of nickel ion adsorption obtained in the previous analysis.

The adsorption process was performed over 1 h, which was an optimal and sufficient time to establish the adsorption equilibrium, which clearly confirms the withdrawn dependencies c e = f(t), where c e is the equilibrium concentration of nickel ions calculated per unit mass of the adsorbent; see Fig. 8a.

Analyzing the obtained curves, it can be concluded that the 1 h duration of the adsorption process, in the case of model solutions in concentrations of 0.25, 0.50 and 1.00 g/dm3, is sufficient to establish the equilibrium state. With the increase in concentration of the nickel(II) ions precursor, the amount of metal adsorbed onto the synthetic oxide adsorbent increases. Moreover, to confirm the results presented earlier, the dependence c e = f(pH) is shown in Fig. 8b. The results obtained strictly correlate with the Pourbaix diagram for nickel (Fig. 9), which confirms that at pH > 8 nickel precipitates as hydroxide Ni(OH)2, or occurs as anions such as Ni(OH) −3 , Ni(OH) 2−4 , and only at pH ≤ 8 does it occur as Ni2+ ions. Moreover, studies realized in an analyzed concentration range of the model solutions of nickel(II) shows that the precipitation of the nickel ions in the form of hydroxide begins at pH = 7.5. Simulation of suitable forms of nickel also shows that above that pH dominant form of nickel is Ni(OH)2, and after exceeding pH = 10.1 nickel occurs in the water solutions as a Ni(OH) −3 and Ni(OH) 2−4 . At pH of less than 7.5 this metal occurs in the form of Ni2+ ions, and partially hydrolyzed forms of NiOH+. It is not unequivocal that there is no adsorption. To a certain extent nickel precipitation may occur, but on the other hand the pH of the reaction system was changed after the adsorbent was mixed with a model solution of nickel(II) ions. Therefore the selected adsorbents used in the process were analyzed to determine their electrokinetic properties, to evaluate the changes in the surface charge density as a result of adsorption of the counter ions, induced also by changes in pH. Figure 10 shows the electrokinetic curves of the analyzed oxide adsorbents.

Analysis of the results indicates the similar character of the electrokinetic curves of the adsorbents used in comparison with the curve of the MgO·SiO2 oxide system. Over practically the entire analyzed pH range those systems have a negative value of the electrokinetic potential—even up to −40 mV—which proves their significant stability in an aqueous system. Noteworthy, however, are the changes in the IEP values (the isoelectric point, the pH at which the zeta potential is zero). The main effect on the IEP comes from a change in the density of electric charge on the solid surface caused by the change in pH of the reaction system or the adsorption of ions of opposite sign—counter ions (Kosmulski 2001). IEP values in each of the analyzed cases increase with the concentration of the model solution of nickel salt from which the metal was adsorbed. In addition, the highest IEP values were obtained for a process of adsorption at pH = 11, which directly correlates with previous findings. Adsorbent IEP values of 3.54, 3.66 and 3.68 are found for the adsorption process realized using nickel(II) nitrate solutions in concentrations of 0.25, 0.50 and 1.00 g/dm3, respectively. This is unequivocal confirmation of the presence of nickel ions in the structure of the MgO·SiO2 oxide system, which have effectively bound to its surface as a result of the adsorption process. Based on the results given, a schematic mechanism of adsorbent/adsorbate interactions was proposed (Fig. 11).

Indirect confirmation of the effectiveness of nickel ion adsorption using inorganic oxide adsorbent is provided by the change in the colorimetric parameters and adsorption properties of the adsorbents.

Colorimetric analysis was performed because of the color change of the synthetic oxide adsorbent during the adsorption process, resulting from the use of nickel(II) salt solutions, which have a green color. Figure 12 presents a graphical interpretation of the colorimetric parameters. Analyzing the colorimetric data obtained, it was found that the brightness (L* factor) values decreased from 93.85 for the synthetic adsorbent used in the adsorption process, to a value of 90.88–93.68 for the adsorbents after the completed process. Another very important parameter is the contribution of green −a* = 0.11–(−3.29) and yellow +b* = 3.09–5.48, which increased in comparison with the initial adsorbent sample (+a* = 0.21 and +b* = 2.82), and also indicates the staining of the adsorbents. A similar relationship was observed in the case of parameter dE, corresponding to the total change in the color of the oxide systems. The changes were more pronounced the higher the concentration of nickel ions used in the process of adsorption.

Similar dependencies were obtained on evaluating the adsorption properties of the adsorbents used. Table 4 shows the changes in the basic parameters affecting the adsorption properties of inorganic oxide systems.

In any case, independently of the pH of the process and the model solution concentration, a decrease in the surface area value of adsorbents was noted compared with the initial MgO·SiO2 sample (ABET = 427 m2/g). Realization of the adsorption process at acidic pH (pH = 2) gave the highest adsorbent surface areas, 368 and 366 m2/g, respectively using model adsorbate solutions in concentration 0.50 and 1.00 g/dm3. Following the process conducted in a neutral medium (pH = 7.5) the adsorbents have lower surface areas (respectively 355 and 339 m2/g) compared with the values for pH = 2. In turn, the process of adsorption carried out in a basic medium (pH = 11) yielded the lowest surface area of the adsorbent, equal to 320 m2/g when using nickel(II) nitrate solution in a concentration of 1 g/dm3. An important fact is that, in most cases, with increasing pH of the reaction system and increasing concentration of the nickel ions’ precursor, the surface area was observed to decrease. Evaluating the adsorption parameters of the oxide systems, their pore size distribution before and after the adsorption process was estimated. Analyzing the data in Table 4, it was found that in each case, regardless of the pH of the reaction system and the concentration of model nickel salt solutions, a decrease in the pore volume to a value of Vp = 0.25–0.27 cm3/g and the pore diameter to Sp = 2.7–2.8 nm was noted as compared with the reference sample (Vp = 0.49 cm3/g and Sp = 4.5 nm). The estimated adsorption properties of the synthetic oxide adsorbent after adsorption of nickel(II) ions, carried out at different pH, mostly correlate with the previously obtained efficiency results, EDS analysis and colorimetric analysis.

Ismail et al. (2008) described the effect of different parameters on the efficiency of adsorption of nickel(II) and cadmium(II) ions. A TiO2·SiO2 inorganic oxide system was used as the adsorbent. The studies concentrated on the effect of pH (2–8), time of the process with shaking (6–24 h) and concentration of metal ions (5–10 ppm) on the efficiency of adsorption of nickel(II) and cadmium(II) ions. The pH proved to be the most significant factor influencing the efficiency of adsorption on the TiO2·SiO2 inorganic oxide system. In the case of pH = 2, the efficiency of adsorption was 30–35 %, while with increasing basicity of the system (pH = 8) the efficiency was approximately 100 %. The best results were obtained for the adsorption carried out over 6 h with a metal ion concentration of 10 ppm, both for the nickel(II) and cadmium(II) ions. Jiang et al. (2010) studied the influence of pH, concentration of selected metal ions and time of the process on the efficiency of adsorption of nickel(II), cadmium(II), copper(II) and lead(II) ions. In this case kaolinite was used as adsorbent. Better results for metal ion adsorption were obtained with increasing pH. However the duration of the process does not have a major impact on the efficiency of removal of selected metal ions, although an increase in the concentration of metal ions used in the adsorption process resulted in a decrease in its efficiency. Padilla-Ortega et al. (2011) analyzed the possibility of using sepiolite as an adsorbent of nickel(II), copper(II), cadmium(II), zinc(II) and chromium(III) ions. The main objective of the study was to determine the effect of pH on the adsorption efficiency of selected metal ions. The tests were performed in a pH range of 2–7. Below pH = 2 the adsorbent was not stable. With increasing pH, an increase in the adsorption capacity of sepiolite was observed. Confirmation of the physicochemical analysis performed during the studies may come from the question of the different forms in which nickel occurs, depending on the pH, and determined by the dependence of the equilibrium potential on the pH. Thus up to neutral pH (pH = 7) nickel ions in water solutions occur mainly as Ni2+, while for higher pH values the hydroxide form of nickel starts to dominate. This is very important in the process of adsorption of nickel(II) ions, especially with the use of precipitated MgO·SiO2 inorganic oxide systems. On the surface of the oxide systems thus prepared, it is mostly silanol and magnesil groups terminating in –OH that are present. Condensation of those groups with the –OH groups of the hydroxide form of nickel, existing mainly in alkaline pH, should result in a higher efficiency of the bonding of the metal to the surface of the adsorbent, which was in fact confirmed by the physicochemical studies.

The process parameters described above, which significantly affect the removal of metal ions from aqueous solutions, show that the adsorption process can be fully controlled. This makes it possible to achieve almost 100 % efficiency of adsorption of heavy metal ions. These advantages suggest that the process of adsorption has very good potential for application. The use of adsorbents in the purification of aqueous solutions by removal of heavy metal ions is an innovative and forward-looking technological method.

4 Conclusions

The study showed that the pH of the reaction system and the type of adsorbate have a significant influence on the efficiency of nickel(II) ion adsorption from a model metal salt solution on a synthetic oxide adsorbent (MgO·SiO2). The lowest effectiveness of adsorption was recorded when the process was realized an acidic medium, while the best results were obtained by adsorbing nickel in an alkaline medium (pH = 11). Irrespective of the pH of the reaction and the concentration of model nickel(II) salt, the significant stability of adsorbent/adsorbate bonding was confirmed, as evidenced by elution tests. The EDS analysis performed also confirmed the effectiveness of the adsorption process. The smallest amount of nickel in the structure of the adsorbent was obtained after the process realized in an acidic medium. When it was conducted in an alkaline medium the amount of metal in the structure of the adsorbent was the highest.

Valuable results were supplied by analysis of the electrokinetic properties of the inorganic oxide systems used as adsorbents of Ni(II). Experimental data proved changes in the density of electric charge on the surface of the adsorbent as a result of the process of adsorption of nickel ions. The changes were most significant in the most basic environment in which the adsorption process was carried out, which clearly confirms the adsorption efficiencies obtained.

Colorimetric tests of the adsorbents after the adsorption process showed changes in the basic color parameters of the synthetic oxide system. An additional confirmation of the previous assumptions is given by analysis of the adsorption properties. Interpretation of the experimental data indicated a decrease in the surface area, pore volume and diameter of the MgO·SiO2 oxide system used in the adsorption process. These changes were more significant the greater the basicity of the reaction system.

The results obtained clearly indicate the effectiveness of the adsorption process of nickel(II) ions, whose precursors were model nitrate(V) solutions, using a synthetic oxide system. Moreover, the study determined the optimal conditions of the process, which will facilitate its implementation in real systems, such as in the treatment of wastewater containing nickel(II) or other heavy metal ions.

References

Amin, G., Zaman, S., Zainelabdin, A., Nur, O., Willander, M.: ZnO nanorods–polymer hybrid white light emitting diode grown on a disposable paper substrate. Phys. Status Solidi RRL 5, 71–73 (2011)

Argun, M.E.: Use of clinoptylolite fort he removal of nickel ions from water: kinetics and thermodynamics. J. Hazard. Mater. 150, 587–595 (2008)

Benguella, B., Benaissa, H.: Cadmium removal from aqueous solutions by chitin: kinetic and equilibrium studies. Water Res. 36, 2463–2474 (2002)

Betancur, M., Bonelli, P.R., Velásquez, J.A., Cukierman, A.L.: Potentiality of lignin from the Kraft pulping process for removal of trace nickel from wastewater: effect of demineralization. Bioresour. Technol. 100, 1130–1137 (2009)

Chen, Y.X., Zhong, B.H., Fang, W.M.: Adsorption characterization of lead(II) and cadmium(II) on crosslinked carboxymethyl starch. J. Appl. Polymer Sci. 124, 5010–5020 (2012)

Ciesielczyk, F., Jesionowski, T.: Heat treatment of inorganic oxide systems and its effect on the physicochemical properties and potential directions of application. Przem. Chem. 90, 720–725 (2011)

Ciesielczyk, F., Nowacka, M., Przybylska, A., Jesionowski, T.: Dispersive and electrokinetic evaluations of alkoxysilane-modified MgO-SiO2 oxide composite and pigment hybrids supported on it. Colloids Surf. A: Physicochem. Eng. Aspects 376, 21–30 (2011)

Dhir, B., Srivastava, S.: Heavy metal removal from a multi-metal solution and wastewater by Salvinia natans. Ecol. Eng. 37, 893–896 (2011)

Engates, K.E., Shipley, H.J.: Adsorption of Pb, Cd, Cu, Zn, and Ni to titanium dioxide nanoparticles: effect of particle size, solid concentration, and exhaustion. Environ. Sci. Pollut. Res. 18, 386–395 (2011)

Fosso-Kankeu, E., Mulaba-Bafubiandi, A.F., Mamba, B.B., Barnard, T.G.: Prediction of metal-adsorption behaviour in the remediation of water contamination using indigenous microorganisms. J. Environ. Manag. 92, 2786–2793 (2011)

Gandhi, M.R., Meenakshi, S.: Preparation and characterization of silica gel/chitosan composite for the removal of Cu(II) and Pb(II). Int. J. Bio. Macromol. 50, 650–657 (2012)

Ismail, A.A., El-Midany, A.A., Ibrahim, I.A., Matsunaga, H.: Heavy metal removal using SiO2-TiO2 binary oxide: experimental design approach. Adsorption 14, 21–29 (2008)

Jiang, M., Jin, X., Lu, X., Chen, Z.: Adsorption of Pb(II), Cd(II), Ni(II) and Cu(II) onto natural kaolinite clay. Desalination 252, 33–39 (2010)

Johnson, J.H., McFarlane, A.J., Bormann, T., Moraes, J.: Nano-structured silicas and silicates—new materials and their applications in paper. Curr. Appl. Phys. 4, 411–414 (2004)

Li, Q., Su, H., Tan, T.: Synthesis of ion-imprinted chitosan-TiO2 adsorbent and its multi-functional performances. Biochem. Eng. J. 38, 212–218 (2008)

Klapiszewski, L., Madrawska, M., Jesionowski, T.: Preparation and characterisation of hydrated silica/lignin biocomposites. Physicochem. Probl. Miner. Process. 48, 463–473 (2012)

Kosmulski, M.: Chemical Properties of Material Surfaces. Marcel Dekker, New York (2001)

Kumar, Ch.S.S.R.: Nanostructured Oxides. Wiley-VCH, Weinheim (2009)

Lewis, A.E.: Review of metal sulphide precipitation. Hydrometallurgy 104, 222–234 (2010)

Majdan, M., Pikus, S., Gajowiak, A., Gładysz-Płaska, A., Krzyzanowska, H., Zuk, J., Bujacka, M.: Characterization of uranium(VI) sorption by organobentonite. Appl. Surf. Sci. 256, 5416–5421 (2010)

Maturana, A.H., Perič, I.M., Rivas, B.L., Pooley, S.A.: Interaction of heavy metal ions with an ion exchange resin obtained from a natural polyelectrolyte. Polymer Bull. 67, 669–676 (2011)

Mendoza-Barrón, J., Jacobo-Azuara, A., Leyva-Ramos, R., Berber-Mendoza, M.S., Guerrero-Coronado, R., Fuentes-Rubio, L., Martínez-Rosales, J.: Adsorption of aresnic(V) from a water solution onto a surfactant-modified zeolite. Adsorption 17, 489–496 (2011)

Modrzejewska-Sikorska, A., Ciesielczyk, F., Jesionowski, T.: Synthesis of inorganic oxide composites with the use of postgalvanic waste solutions of copper(II) sulfate. Polish J. Chem. Technol. 12, 46–51 (2010)

Moreno-Piraján, J.C., Garcia-Cuello, V.S., Giraldo, L.: The removal and kinetic study of Mn, Fe, Ni and Cu ions from wastewater onto activated carbon from coconut shells. Adsorption 17, 505–514 (2011)

Mungray, A.A., Kulkarni, S.V., Mungray, A.K.: Removal of heavy metals from wastewater using micellar enhanced ultrafiltration technique: a review. Cent. Eur. J. Chem. 10, 27–46 (2012)

Onundi, Y.B., Mamun, A.A., Al Khatib, M.F., Al Saadi, M.A., Suleyman, A.M.: Heavy metals removal from synthetic wastewater by a novel nano-size composite adsorbent. Int. J. Environ. Sci. Tech. 8, 799–806 (2011)

Padilla-Ortega, E., Leyva-Ramos, R., Mendoza-Barron, J., Guerrero-Coronado, R.M., Jacobo-Azuara, A., Aragon-Piña, A.: Adsorption of heavy metal ions from aqueous solution onto sepiolite. Adsorpt. Sci. Technol. 29, 569–584 (2011)

Regel-Rosocka, M., Cieszyńska, K., Wiśniewski, M.: Extraction of zinc(II) with selected phosphonium ionic liquids. Przem. Chem. 85, 651–654 (2006)

Sheng, G., Wang, S., Hu, J., Lu, Y., Li, J., Dong, Y., Wang, X.: Adsorption of Pb(II) on diatomite as affected via aqueous solution chemistry and temperature. Colloids Surf. A: Physicochem. Eng. Aspects 339, 159–166 (2009)

Singhon, R., Husson, J., Knorr, M., Lakard, B., Euvrard, M.: Adsorption of Ni(II) ions on colloidal hybrid organic–inorganic silica composites. Colloids Surf. B: Biointerfaces 93, 1–7 (2012)

Siwińska-Stefańska, K., Nowacka, M., Kołodziejczak-Radzimska, A., Jesionowski, T.: Preparation of hybrid pigments via adsorption of selected food dyes onto inorganic oxides based on anatase titanium dioxide. Dyes Pigment 94, 338–348 (2012)

Tofighy, M.A., Mohammadi, T.: Adsorption of divalent heavy metal ions from water using carbon nanotube sheets. J. Hazard. Mater. 185, 140–147 (2011)

Acknowledgments

The study was realized within the Polish National Centre of Science research grant no. 2011/03/D/ST5/05802.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Ciesielczyk, F., Bartczak, P., Wieszczycka, K. et al. Adsorption of Ni(II) from model solutions using co-precipitated inorganic oxides. Adsorption 19, 423–434 (2013). https://doi.org/10.1007/s10450-012-9464-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10450-012-9464-5