Abstract

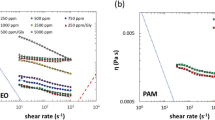

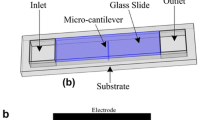

We present a microfluidic rheometer that uses in situ pressure sensors to measure the viscosity of liquids at low Reynolds number. Viscosity is measured in a long, straight channel using a PDMS-based microfluidic device that consists of a channel layer and a sensing membrane integrated with an array of piezoresistive pressure sensors via plasma surface treatment. The micro-pressure sensor is fabricated using conductive particles/PDMS composites. The sensing membrane maps pressure differences at various locations within the channel in order to measure the fluid shear stress in situ at a prescribed shear rate to estimate the fluid viscosity. We find that the device is capable to measure the viscosity of both Newtonian and non-Newtonian fluids for shear rates up to 104 s−1 while keeping the Reynolds number well below 1.

Similar content being viewed by others

References

Abyaneh MK, Kulkarni SK (2008) Giant piezoresistive response in zinc-polydimethylsiloxane composites under uniaxial pressure. J Phys D Appl Phys 41(13):135405

Arratia PE, Voth GA, Gollub JP (2005) Stretching and mixing of non-newtonian fluids in time-periodic flows. Phys Fluids 17:053102

Arratia PE, Thomas CC, Diorio J, Gollub JP (2006) Elastic instabilities of polymer solutions in cross-channel flow. Phys Rev Lett 96:144502

Chuang HS, Wereley S (2009) Design, fabrication and characterization of a conducting pdms for microheaters and temperature sensors. J Micromech Microeng 19(4):045010

Crocker JC, Grier DG (1996) Methods of digital video microscopy for colloidal studies. J Colloid Interf Sci 179:298–310

Eddings MA, Johnson MA, Gale BK (2008) Determining the optimal pdms–pdms bonding technique for microfluidic devices. J Micromech Microeng 18(6):067001

Gisler T, Weitz DA (1998) Tracer microrheology in complex fluids. Curr Opin Colloid Interf Sci 3(6):586–592

Gittes F, Schnurr B, Olmsted PD, MacKintosh FC, Schmidt CF (1997) Microscopic viscoelasticity: shear moduli of soft materials determined from thermal fluctuations. Phys Rev Lett 79(17):3286–3289

Jo BH, Lerberghe LMV, Motsegood KM, Beebe DJ (2000) Three-dimensional micro-channel fabrication in polydimethylsiloxane (pdms) elastomer. J Microelectromech Syst 9(1):76–81

Kang K, Lee LJ, Koelling KW (2005) High shear microfluidics and its application in rheological measurement. Exp Fluids 38(2):222–232

Kim K, Pak HK (2010) Diffusing-wave spectroscopy study of microscopic dynamics of three-dimensional granular systems. Soft Matter 6(13):2894–2900

Larson RG (1999) The rheology and structure of complex fluids. Oxford University Press, Oxford

Larson RG, Shaqfeh ESG, Muller SJ (1990) Purely elastic instability in Taylor–Couette flow. J Fluid Mech 218:573–600

Laun HM (1983) Polymer melt rheology with a slit die. Rheol Acta 22(2):171–185

Li H, Luo CX, Ji H, Ouyang Q, Chen Y (2010) Micro-pressure sensor made of conductive pdms for microfluidic applications. Microelectro Eng 87(5-8):1266–1269

Lipomi DJ, Vosgueritchian M, Tee BCK, Hellstrom SL, Lee JA, Fox CH, Bao Z (2011) Skin-like pressure and strain sensors based on transparent elastic films of carbon nanotubes. Nat Nanotechnol 6:788–792

Liu C (2007) Recent developments in polymer mems. Adv Mater 19(22):3783–3790

Macosko CW (1994) Rheology principles, measurements, and applications. Wiley-VCH, Weinheim

Mason TG, Weitz DA (1995) Optical measurements of frequency-dependent linear viscoelastic moduli of complex fluids. Phys Rev Lett 74(7):1250–1253

McDonald JC, Whitesides GW (2002) Poly(dimethylsiloxane) as a material for fabricating microfluidic devices. Acc Chem Res 35(7):491–499

Niu XZ, Peng SL, Liu LY, Wen WJ, Sheng P (2007) Characterizing and patterning of pdms-based conducting composites. Adv Mater 19(18):2682

Nordstrom KN, Verneuil E, Arratia PE, Basu A, Zhang Z, Yodh AG, Gollub JP, Durian DJ (2010) Microfluidic rheology of soft colloids above and below jamming. Phys Rev Lett 105:175,701

Orth A, Schonbrun E, Crozier KB (2011) Multiplexed pressure sensing with elastomer membranes. Lab Chip 11(22):3810–3815

Palmer A, Mason TG, Xu JY, Kuo SC, Wirtz D (1999) Diffusing wave spectroscopy microrheology of actin filament networks. Biophys J 76(2):1063–1071

Pipe CJ, Majmudar TS, McKinley GH (2008) High shear rate viscometry. Rheol Acta 47(5-6):621–642

Quake SR, Scherer A (2000) From micro- to nanofabrication with soft materials. Science 290(5496):1536–1540

Schultz KM, Furst EM (2011) High-throughput rheology in a microfluidic device. Lab Chip 11(22):3802–3809

Shen XN, Arratia PE (2011) Undulatory swimming in viscoelastic fluids. Phys Rev Lett 106:208,101

Sia SK, Whitesides GM (2003) Microfluidic devices fabricated in poly(dimethylsiloxane) for biological studies. Electrophoresis 24(21):3563–3576

Strumpler R, Glatz-Reichenbach J (1999) Conducting polymer composites. J Electroceram 3:329–346

Toker D, Azulay D, Shimoni N, Balberg I, Millo O (2003) Tunneling and percolation in metal-insulator composite materials. Phys Rev B 68(4):041,403

Wang L, Zhang M, Yang M, Zhu W, Wu J, Gong X, Wen W (2009) Polydimethylsiloxane-integratable micropressure sensor for microfluidic chips. Biomicrofluidics 3:034,105

Wu CY, Liao WH, Tung YC (2011) Integrated ionic liquid-based electrofluidic circuits for pressure sensing within polydimethylsiloxane microfluidic systems. Lab Chip 11(10):1740–1746

Xia YN, Whitesides GM (1998) Soft lithography. Annu Rev Mater Sci 28:153–184

Acknowledgements

The authors would like to thank J. Grogan for fruitful discussions on micro-fabrication, N. Keim for help with characterization of the sensing membrane as well as G. Juarez and X. N. Shen for helpful discussions. The work is partially supported by NSF-CAREER-CBET-0954084 and by NSF-CBET-0932449.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Pan, L., Arratia, P.E. A high-shear, low Reynolds number microfluidic rheometer. Microfluid Nanofluid 14, 885–894 (2013). https://doi.org/10.1007/s10404-012-1124-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-012-1124-2