Abstract

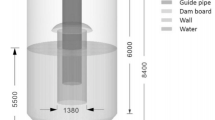

Due to their wide usage in industrial and technological processes, granular materials have captured great interest in recent research. The related studies are often based on numerical simulations and it is challenging to investigate computational phenomena of granular systems. Particle screening is an essential technology of particle separation in many industrial fields. This paper presents a numerical model for studying the particle screening process using the discrete element method that considers the motion of each particle individually. Dynamical quantities like particle positions, velocities and orientations are tracked at each time step of the simulation. The particular problem of interest is the separation of round shape particles of different sizes using a rotating tumbling vertical cylinder while the particulate material is continuously fed into its interior. This rotating cylinder can be designed as a uniform or stepped multi level obliqued vertical vessel and is considered as a big reservoir for the mixture of particulate material. The finer particles usually fall through the sieve openings while the oversized particles are rebounded and ejected through outlets located around the machine body. Particle–particle and particle–boundary collisions will appear under the tumbling motion of the rotating structure. A penalty method, which employs spring-damper models, will be applied to calculate the normal and frictional forces. As a result of collisions, the particles will dissipate kinetic energy due to the normal and frictional contact losses. The particle distribution, sifting rate of the separated particles and the efficiency of the segregation process have been studied. It is recognized that the screening phenomenon is very sensitive to the machines geometrical parameters, i.e. plate inclinations, shaft eccentricities and aperture sizes in the sieving plates at different levels of the structure. The rotational speed of the machine and the feeding rate of the particles flow have also a great influence on the transportation and segregation rates of the particles. In an attempt to better understand the mechanism of the particle transport between the different layers of the sifting system, different computational studies for achieving optimal operation have been performed.

Similar content being viewed by others

References

Alexander A., Shinbrot T. and Muzzio F. (2001). Granular segregation in the double-cone blender: transitions and mechanisms. Phys. Fluids 13(3): 578–587

Alkhaldi, H., Eberhard, P.: Computation of screening phenomena in a vertical tumbling cylinder. In: Proceedings in Applied Mathematics and Mechanics (PAMM) (2006, submitted)

Alkhaldi, H., Eberhard, P.: Efficient computation of colliding particles in a vertical tumbling sorting machine. In: Proceedings Second International Congress on Computational Mechanics and Simulation (ICCMS), Guwahati, India (2006)

Allen M. and Tildesley D. (1987). Computer Simulation of Liquids. Clarendon, Oxford

Beverloo W., Leniger H. and Velde J. (1961). The flow of granular solids through orifices. Chem. Eng. Sci. 15: 260–269

Cundall P. and Strack O. (1979). A discrete numerical model for granular assemblies. Geotechnique 29: 47–65

Dury C. and Ristow G. (1999). Competition of mixing and segregation in rotating cylinders. Phys. Fluids 11(6): 1387–1394

Jansen M. and Glastonbury J. (1967). The size separation of particles by screening. Powder Technol. 1: 334–343

Kaye B. and Robb N. (1979). An algorithm for deducing an effective sieve residue from the rate of powder passage through a sieve. Powder Technol. 24: 125–128

Kelly E. and Spottiswood D. (1999). Introduction to Mineral Processing. Wiley-Interscience, New York

Khakhar D., McCarthy J. and Ottino M. (1997). Radial segregation of granular mixtures in rotating cylinders. Phys. Fluids 9(12): 3600–3614

Lee J. and Ladd A. (2005). Axial segregation of a settling suspension in a rotating cylinder. Phys. Rev. Lett. 95: 1–4

Li J., Webb C., Pandiella S. and Campbell G. (2002). A numerical simulation of separation of crop seeds by screening-effect of particle bed depth. Inst. Chem. Eng. IChemE Part C 80: 109–117

Li J., Webb C., Pandiella S. and Campbell G. (2003). Discrete particle motion on sieves—a numerical study using the DEM simulation. Powder Technol. 133: 190–202

Mishra B. and Rajamani R. (1992). The discrete element method for the simulation of ball mills. Appl. Math. Modell. 16: 598–604

Mishra B. and Thornton C. (2002). An improved contact model for ball mill simulation by the discrete element method. Adv. Powder Technol. 13(1): 25–41

Muth, B.: Simulation von Kontaktvorgängen einfacher Körper mit Methoden der Molekulardynamik (in German), DIPL-87, Institute B of Mechanics, University of Stuttgart, Germany (2001)

Muth B., Müller M., Eberhard P. and Luding S. (2004). Contacts between many bodies. Mach. Dyn. Probl. 28(1): 101–114

Nakagawa M. (1994). Axial segregation of granular flows in a horizontal rotating cylinder. Chem. Eng. Sci. 49(15): 2540–2544

Rhodes M. (2005). Introduction to Particle Technology. Wiley-Interscience, Chichester

Sawley, L., Cleary, W.: Parallel Discrete-Element Method for Industrial Granular Flow Simulation. Csiro Mathematical & Information Sciences, Clayton, Australia (1999)

Schiehlen W. and Eberhard P. (2004). Technische Dynamik (in German). Teubner, Stuttgart

Schinner A. (1999). Fast algorithms for the simulation of polygonal particles. Granular Matter 2: 35–43

Shabana A. (1989). Dynamics of Multibody Systems. Wiley-Interscience, New York

Standish N. (1985). The kinetics of batch sieving. Powder Technol. 41: 57–67

Standish N., Bharadwaj A. and Hariri-Akbari G. (1986). A study of the effect of operating variables on the efficiency of a vibrating screen. Powder Technol. 48: 161–172

Standish N. and Meta I. (1985). Some kinetic aspects of continuous screening. Powder Technol. 41: 165–171

Subasinghe G., Schaap W. and Kelly E. (1989). Modelling the screening process: a probabilistic approach. Powder Technol. 59: 37–44

Takahashi Y., Kataoka M., Uekusa M. and Terumichi Y. (2005). Behavior of three kinds of particles in rotary barrel with planetary rotation. Multibody Syst. Dyn. 13(2): 195–209

Tsuji Y., Tanaka T. and Ishida T. (1991). Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technol. 71: 239–250

Wessel J. (1963). Siebmaschinen (in German). Aufbereitungstechnik 2: 449–456

Yamane K., Nakagawa M., Tanaka T. and Tsuji Y. (1998). Steady particulate flows in a horizontal rotating cylinder. Phys. Fluids. 10(6): 1419–1427

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alkhaldi, H., Eberhard, P. Particle screening phenomena in an oblique multi-level tumbling reservoir: a numerical study using discrete element simulation. Granular Matter 9, 415–429 (2007). https://doi.org/10.1007/s10035-007-0042-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10035-007-0042-6