Abstract

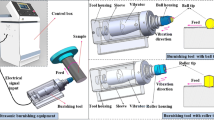

Burnishing is a mechanical finishing operation performed on workpieces to enhance their surface quality through plastic deformation. One of the main issues to understand the overall process is the behavior of the elastoplastic deformations caused by the burnishing ball on the workpiece. The first burnishing passes performed on the workpiece surface lead to its plastic strain and self-hardening, thus influencing the results of consecutive passes. Some references have studied the phenomenon of indentation, finding that there is a certain self-hardening coefficient threshold which allows to predict the presence of pile-ups at the edges of the indentation path. Nevertheless, burnishing is not a single-pass operation. On the contrary, burnishing a whole surface requires successive adjacent and/or overlapping passes, i.e., parallel passes separated consecutively a certain lateral pass width. No reference has been found in the literature defining the adequate values of the lateral pass width with regards to the pile-up effect to enhance the final topology of the burnished surface. This paper explores that influence by studying the presence of the pile-up effect after burnishing a single or several overlapping passes on two materials (aluminum and steel), by characterizing the topology of the generated path. Afterwards, two adjacent passes are performed, varying the lateral pass width, to compare the final surface roughness derived from each operation. An optimum value for the lateral pass width was found, to improve the final roughness after burnishing in different conditions and to increase the productivity of the process.

Similar content being viewed by others

References

Hamadache H, Laouar L, Zeghib NE, Chaoui K (2006) Characteristics of Rb40 steel superficial layer under ball and roller burnishing. J Mater Process Tech 180:130–136

Luca L (2002) Investigation into the use of ball burnishing of hardened steel components as a finishing process. PhD Dissertation, University of Toledo, USA

Nemat M, Lyons AC (2000) An investigation of the surface topography of ball burnished mild steel and aluminum. Int J Adv Manuf Tech 16:460–473

Loh N H (1998) Effects of ball burnishing parameters on surface finish. a literature survey and discussion. Precis Eng 10:215–220

Prevey PS, Ravindranath RA, Shepard M, Gabb T (2003) Case studies of fatigue life improvement using low plasticity burnishing in gas turbine engine applications proceedings of ASME turbo expo. Atlanta, USA

Hassan AM, Sulieman ZS (1999) Improvement in the wear resistance of brass components by the ball burnishing process. J Mater Process Tech 96:73–80

Altenberger I, Nalla RK, Sano Y, Wagner L, Ritchie RO (2012) On the effect of deep-rolling and laser-peening on the stress-controlled low-and high-cycle fatigue behavior of Ti–6Al–4V at elevated temperatures up to 550 C. Int J Fatigue 44:292–302

Nalla RK, Altenberger I, Noster U, Liu GY, Scholtes B, Ritchie RO (2003) On the influence of mechanical surface treatments -deep rolling and laser shock peening- on the fatigue behavior of Ti–6Al–4V at ambient and elevated temperatures. Mat Sci Eng A-Struct 355(1):216–230

Shiou FJ, Chen CH (2003) Freeform surface finish of plastic injection mould by using ball burnishing process. J Mater Process Tech 140:248–254

Travieso-Rodriguez J A, Gonzalez-Rojas H A, Casado-Lopez R (2013) Herramienta con bola a baja presion, aplicable para bruñido de superficies. Spanish patent reference: P201130331. Boletin Oficial de la Propiedad Intelectual BOPI 21(11)

Lopez de la Calle LN, Rodriguez A, Lamikiz A, Celaya A, Alberdi R (2011) Five-Axis Machining and burnishing of complex parts for the improvement of surface roughness. Mater Manuf Process 26(8):997–1003

Hassan AM, Maqableh AM (2000) The effects of initial burnishing parameters on non-ferrous components. J Mater Process Tech 102:115–121

Yen YC, Altan T (2004) Finite element modelling of ball burnishing prediction of surface deformation and residual stress. ERC Report No. HPM/ERC/NSM-04-R-04, Ohio State University

Lopez de la calle LN, Lamikiz A, Sanchez JA, Arana JL (2007) The effect of ball burnishing on heat-treated steel and Inconel 718 milled surfaces. Int J Adv Manuf Tech 32(9–10):958–968

Gao XL (2003) Strain gradient plasticity solution for an internally pressurized thick-walled spherical shell of an elastic-plastic material. Mech Res Commun 30:411–420

Gao XL, Jing XN, Subhash G (2006) Two new expanding cavity models for indentation deformation of elastic strain-hardening materials. Int J Solids Struct 43:2193–2208

Sequera A, Fu CH, Guo YB, Wei XT (2014) Surface integrity of inconel 718 by ball burnishing. J Mater Eng Perform 23(9):3347–3353

Qu S, Huang Y, Pharr GM, Hwang KC (2005) The indentation size effect in the spherical indentation of iridium: a study via the conventional theory of mechanism-based gradient plasticity. Int J Plasticity 22:1265–1286

Nix WD, Gao H (1998) Indentation size effects in crystalline materials: a law for strain gradient plasticity. J Mech Phys Solids 46:411–425

Hernot X, Bartier O, Bekouche Y, El Abdi R, Mauvoisin G (2006) Influence of penetration depth and mechanical properties on contact radius determination for spherical indentation. Int J Solids Struct 43:4136–4153

Gomez-Gras G, Travieso-Rodriguez J A, Gonzalez-Rojas HA, Napoles-Alberro A, Carrillo F, Dessein G (2015a) Study of a ball burnishing vibration-assisted process. P I Mech Eng B-J Mec 229(1):172–177

Gomez-Gras G, Travieso-Rodriguez JA, Gonzalez-Rojas H A, Napoles-Alberro AE (2012) Influence of peak height prior to milling the resulting surface roughness of the ball burnishing process on convex and concave pieces of aluminum. In: Proceedings of the third international conference on surface metrology (ICSM3), Annecy, France, pp 26–34

Travieso-Rodriguez JA, Dessein G, Gonzalez-Rojas HA (2011) Improving the surface finish of concave and convex surfaces using a ball burnishing process. Mater Manuf Process 26(12):1494–1502

Travieso-Rodriguez JA, Gomez-Gras G, Dessein G, Carrillo F, Alexis J, Jorba-Peiro J, Aubazac N (2015b) Effects of a ball-burnishing process assisted by vibrations in G10380 steel specimens. Int J Adv Manuf Tech. doi:10.1007/s00170-015-7255-3

Travieso-Rodriguez J A, Gomez-Gras G, Jorba-Peiro J, Carrillo F, Dessein G, Alexis j, Gonzalez-Rojas H (2015b) Experimental study on the mechanical effects of the vibration-assisted ball burnishing process. Mater Manuf Process. doi:10.1080/10426914.2015.1019114

Gomez-Gras G (2015a) Estudio del proceso de bruñido con bola asistido por una vibracin. PhD dissertation Universitat Politcnica de Catalunya, Barcelona, Spain

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gomez–Gras, G., Travieso–Rodriguez, J.A., Jerez–Mesa, R. et al. Experimental study of lateral pass width in conventional and vibrations-assisted ball burnishing. Int J Adv Manuf Technol 87, 363–371 (2016). https://doi.org/10.1007/s00170-016-8490-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8490-y