Abstract

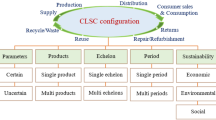

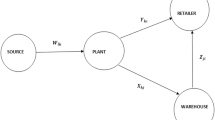

Supply chain (SC) network design problems are complex problems with multi-layer levels and dynamic relationships which involve a considerable amount of uncertainty concerning customer demand, facility capacity, or lead times, among others. A large number of optimization methods (i.e., fuzzy mathematical programming, stochastic programming, and interval mathematical programming) have been proposed to cope with the uncertainties in SC network design problems. We propose a fuzzy bi-objective mixed-integer linear programming (MILP) model to enhance the material flow in dual-channel, multi-item, and multi-objective SCs with multiple echelons under both ambiguous and vague conditions, concurrently. We use a computationally efficient ranking method to resolve the ambiguity of the parameters and propose two methods for resolving the vagueness of the objective functions in the proposed fuzzy MILP model. The preferences of the decision makers (DMs) on the priority of the fuzzy goals are represented with crisp importance weights in the first method and fuzzy preference relations in the second method. The fuzzy preference relations in the second method present a unique practical application of type-II fuzzy sets. The performance of the two methods is compared using comprehensive statistical analysis. The results show the perspicuous dominance of the method which uses fuzzy preference relations (i.e., type-II fuzzy sets). We present a case study in the food industry to demonstrate the applicability of the proposed model and exhibit the efficacy of the procedures and algorithms. To the best of our knowledge, a concurrent interpretation of both ambiguous and vague uncertainties, which is applicable to many real-life problems, is novel and has not been reported in the literature.

Similar content being viewed by others

References

Amiri A (2006) Designing a distribution network in a supply chain system: formulation and efficient solution procedure. Eur J Oper Res 171(2):567–576

Arenas Parra M, Bilbao Terol A, Perez Gladish B, Rodriguez Uria M (2005) Solving a multiobjective possibilistic problem through compromise programming. Eur J Oper Res 164(3):748–759

Azadeh A, Keramati A, Karimi A, Jiryaei Sharahi Z, Pourhaji P (2014) Design of integrated information system and supply chain for selection of new facility and suppliers by a unique hybrid meta-heuristic computer simulation algorithm. Int J Adv Manuf Technol 71(5–8):775–793

Azaron A, Brown KN, Tarim SA, Modarres M (2008) A multi-objective stochastic programming approach for supply chain design considering risk. Int J Prod Econ 116:129–138

Bellman RE, Zadeh LA (1970) Decision-making in a fuzzy environment. Manag Sci 17(4):141–164

Bhatnagar R, Sohal AS (2005) Supply chain competitiveness: measuring the impact of location factors, uncertainty and manufacturing practices. Technovation 25(5):443–456

Bidhandi HM, Mohd Yusuff R (2011) Integrated supply chain planning under uncertainty using an improved stochastic approach. Appl Math Model 35(6):2618–2630

Bidhandi HM, Mohd Yusuff R, Megat Ahmad MMH, Abu Bakar MR (2009) Development of a new approach for deterministic supply chain network design. Eur J Oper Res 198(1):121–128

Bozorgi-Amiri A, Jabalameli M-S, Alinaghian M, Heydari M (2012) A modified particle swarm optimization for disaster relief logistics under uncertain environment. Int J Adv Manuf Technol 60(1–4):357–371

Buckley JJ (1984) Multiple goal non-cooperative conflicts under uncertainty: a fuzzy set approach. Fuzzy Sets Syst 13:107–124

Charnes A, Cooper WW (1961) Management models and industrial application of linear programming. Wiley, New York

Chen CL, Lee WC (2004) Multi-objective optimization of multi-echelon supply chain networks with uncertain product demands and prices. Comput Chem Eng 28(6–7):1131–1144

Chiclana F, Herrera F, Herrera-Viedma E (1998) Integrating three representation models in fuzzy multipurpose decision making based on fuzzy preference relations. Fuzzy Sets Syst 97:33–48

Chiclana F, Herrera F, Herrera-Viedma E (2001) Integrating multiplicative preference relations in a multipurpose decision-making model based on fuzzy preference relations. Fuzzy Sets Syst 122:277–291

Christopher M (1998) Logistics and supply chain management. Pitman, London

Croom S, Romano P, Giannakis M (2000) Supply chain management: an analytical framework for critical literature review. Euro J Purch Supply Manag 6(1):67–83

Dalkey NC, Helmer O (1963) An experimental application of the Delphi method to the use of experts. Manag Sci 9:458–467

Degraeve Z, Roodhooft F (2000) A mathematical programming approach for procurement using activity based costing. J Bus Financ Account 27(1–2):69–98

Dubois D, Fargier H, Fortemps P (2003) Fuzzy scheduling: modelling flexible constraints vs. coping with incomplete knowledge. Eur J Oper Res 147(2):231–252

Dubois D, Prade H (1980) Systems of linear fuzzy constraints. Fuzzy Sets Syst 3(1):37–48

Dubois D, Prade H (1983) Ranking fuzzy numbers in the setting of possibility theory. Inf Sci 30(3):183–224

Dullaert W, Bräysy O, Goetschalckx M, Raa B, Center A (2007) Supply chain (re) design: support for managerial and policy decisions. Eur Transp Infrastruct Res 7(2):73–92

ElMaraghy H, Majety R (2008) Integrated supply chain design using multi-criteria optimization. Int J Adv Manuf Technol 37(3):371–399

Eskigun E, Uzsoy R, Preckel PV, Beaujon G, Krishnan S, Tew JD (2005) Outbound supply chain network design with mode selection, lead times and capacitated vehicle distribution centers. Eur J Oper Res 165(1):182–206

Eskigun E, Uzsoy R, Preckel PV, Beaujon G, Krishnan S, Tew JD (2007) Outbound supply chain network design with mode selection and lead time considerations. Nav Res Logist 54(3):282–300

Fan Z-P, Hu G-F, Xiao S-H (2004) A method for multiple attribute decision-making with the fuzzy preference relation on alternatives. Comput Ind Eng 46:321–327

Fan Z-P, Ma J, Jiang Y-P, Sun Y-H, Ma L (2006) A goal programming approach to group decision making based on multiplicative preference relations and fuzzy preference relations. Eur J Oper Res 174:311–321

Fazel Zarandi M-H, Haddad Sisakht A, Davari S (2011) Design of a closed-loop supply chain (CLSC) model using an interactive fuzzy goal programming. Int J Adv Manuf Technol 56(5–8):809–821

Heilpern S (1992) The expected value of a fuzzy number. Fuzzy Sets Syst 47(1):81–86

Ho C, Chi Y, Tai Y (2005) A structural approach to measuring uncertainty in supply chains. Int J Electron Commer 9(3):91–114

Inuiguchi M, Ichihashi H (1990) Relative modalities and their use in possibilistic linear programming. Fuzzy Sets Syst 35(3):303–323

Inuiguchi M, Ichihashi H, Kume Y (1992) Relationships between modality constrained programming problems and various fuzzy mathematical programming problems. Fuzzy Sets Syst 49(3):243–259

Inuiguchi M, Ramík J (2000) Possibilistic linear programming: a brief review of fuzzy mathematical programming and a comparison with stochastic programming in portfolio selection problem. Fuzzy Sets Syst 111(1):3–28

Inuiguchi M, Sakawa M, Kume Y (1994) The usefulness of possibilistic programming in production planning problems. Int J Prod Econ 33(1–3):45–52

Jayaraman V, Pirkul H (2001) Planning and coordination of production and distribution facilities for multiple commodities. Eur J Oper Res 133(2):394–408

Jiménez M, Arenas M, Bilbao A (2007) Linear programming with fuzzy parameters: an interactive method resolution. Eur J Oper Res 177(3):1599–1609

Kacprzyk J (1986) Group decision making with a fuzzy majority. Fuzzy Sets Syst 18:105–118

Kacprzyk J, Fedrizzi M, Nurmi H (1992) Group decision making and consensus under fuzzy preferences and fuzzy majority. Fuzzy Sets Syst 49:21–31

Keeney S, Hasson RE, McKenna H (2006) Consulting the oracle: 10 lessons from using the Delphi technique in nursing research. J Adv Nurs 53(2):205–212

Khalili-Damghani K, Sadi-Nezhad S (2013) A decision support system for fuzzy multi-objective multi-period sustainable project selection. Comput Ind Eng 64:1045–1060

Khalili-Damghani K, Sadi-Nezhad S, Tavana M (2013) Solving multi-period project selection problems with fuzzy goal programming based on TOPSIS and a fuzzy preference relation. Inf Sci. doi:10.1016/j.ins.2013.05.005

Khalili-Damghani K, Tavana M (2013) A new fuzzy network data envelopment analysis model for measuring the performance of agility in supply chains. Int J Adv Manuf Technol 69(1–4):291–318

Kristianto Y, Zhu L (2013) An integration of assembly planning by design into supply chain planning. Int J Adv Manuf Technol 69(5–8):1593–1604

Lai YJ, Hwang CL (1993) Possibilistic linear programming for managing interest rate risk. Fuzzy Sets Syst 54(2):135–146

Lee BK, Kang KH, Lee YH (2008) Decomposition heuristic to minimize total cost in a multi-level supply chain network. Comput Ind Eng 54(4):945–959

Liang TF (2008) Fuzzy multi-objective production/distribution planning decisions with multi-product and multi-time period in a supply chain. Comput Ind Eng 55(3):676–694

Liu L, Huang GH, Liu Y, Fuller GA, Zeng GM (2003) A fuzzy-stochastic mixed integer robust linear programming approach for regional air quality management. Eng Optim 35(2):177–199

Lu Z, Bostel N (2007) A facility location model for logistics systems including reverse flows: the case of remanufacturing activities. Comput Oper Res 34(2):299–323

Lu J, Zhang G, Ruan D, Wu F (2007) Multi-objective group decision making: methods software and applications with fuzzy set techniques. Imperial College Press, London

Luhandjula MK (1986) Satisfying solutions for a possibilistic linear program. Inf Sci 40(3):247–265

Mirzapour Al-e-Hashem SMJ, Aryanezhad MB, Sadjadi SJ (2012) An efficient algorithm to solve a multi-objective robust aggregate production planning in an uncertain environment. Int J Adv Manuf Technol 58(5–8):765–782

Negoita C (1981) The current interest in fuzzy optimization. Fuzzy Sets Syst 6(3):261–269

Nikolopoulou A, Ierapetritou MG (2012) Optimal design of sustainable chemical processes and supply chains: a review. Comput Chem Eng 44:94–103

Okoli C, Pawloski S (2004) The Delphi method as a research tool: an example, design considerations and applications. Inf Manag 42:15–29

Paksoy T, Pehlivan NY, Özceylan E (2012) Application of fuzzy optimization to a supply chain network design: a case study of an edible vegetable oils manufacturer. Appl Math Model 36(6):2762–2776

Peidro D, Mula J, Jiménez M, del Mar Botella M (2010) A fuzzy linear programming based approach for tactical supply chain planning in an uncertainty environment. Eur J Oper Res 205(1):65–80

Peidro D, Mula J, Poler R, Lario FC (2009) Quantitative models for supply chain planning under uncertainty: a review. Int J Adv Manuf Technol 43(3–4):400–420

Peidro D, Mula J, Poler R, Verdegay JL (2009) Fuzzy optimization for supply chain planning under supply, demand and process uncertainties. Fuzzy Sets Syst 160(18):2640–2657

Pishvaee MS, Kianfar K, Karimi B (2010) Reverse logistics network design using simulated annealing. Int J Adv Manuf Technol 47(1):269–281

Pishvaee MS, Torabi SA (2010) A possibilistic programming approach for closed-loop supply chain network design under uncertainty. Fuzzy Sets Syst 161(20):2668–2683

PrasannaVenkatesan S, Kumanan S (2012) Multi-objective supply chain sourcing strategy design under risk using PSO and simulation. Int J Adv Manuf Technol 61(1–4):325–337

Ramezani M, Bashiri M, Tavakkoli-Moghaddam R (2013) A robust design for a closed-loop supply chain network under an uncertain environment. Int J Adv Manuf Technol 66(5–8):825–843

Ramik J, Rommelfanger H (1993) A single- and multi-valued order on fuzzy numbers and its use in linear programming with fuzzy coefficients. Fuzzy Sets Syst 57(2):203–208

Ramik J, Rommelfanger H (1996) Fuzzy mathematical programming based on some new inequality relations. Fuzzy Sets Syst 81(1):77–88

Romero C (1986) A survey of generalized goal programming (1970–1982). Eur J Oper Res 25:183–191

Romero C (2004) A general structure of achievement functions for a goal programming model. Eur J Oper Res 153:675–686

Rommelfanger H, Slowinski R (1998) Fuzzy linear programming with single or multiple objective functions. Fuzzy sets in decision analysis, operations research and statistics. The handbooks of fuzzy sets series. Kluwer Academic Publ, Boston, pp 179–213

Roodhooft F, Konings J (1997) Vendor selection and evaluation an activity based costing approach. Eur J Oper Res 96(1):97–102

Rubin PA, Narasimhan R (1984) Fuzzy goal programming with nested priorities. Fuzzy Sets Syst 14:115–129

Sadjady H, Davoudpour H (2012) Two-echelon, multi-commodity supply chain network design with mode selection, lead-times and inventory costs. Comput Oper Res 39(7):1345–1354

Selim H, Ozkarahan I (2008) A supply chain distribution network design model: an interactive fuzzy goal programming-based solution approach. Int J Adv Manuf Technol 36(3):401–418

Singh AR, Jain R, Mishra PK (2013) Capacities-based supply chain network design considering demand uncertainty using two-stage stochastic programming. Int J Adv Manuf Technol 69(1–4):555–562

Singh AR, Mishra PK, Jain R, Khurana MK (2012) Design of global supply chain network with operational risks. Int J Adv Manuf Technol 60(1–4):273–290

Steuer RE (1986) Multiple criteria optimization, theory, computation and application. Wiley, New York

Syarif A, Yun YS, Gen M (2002) Study on multi-stage logistic chain network: a spanning tree-based genetic algorithm approach. Comput Ind Eng 43(1–2):299–314

Tanaka H, Okuda T, Asai K (1973) On fuzzy-mathematical programming. J Cybern 3(4):37–46

Tanino T (1990) On group decision making under fuzzy preference. In: Kacprzyk J, Fedrizzi M (eds) Multiperson decision making using fuzzy sets and possibility theory. Kluwer Academic Publishers, Dordrecht, pp 172–185

Tiwari RN, Dharmar S, Rao JR (1987) Fuzzy goal programming—an additive model. Fuzzy Sets Syst 24:27–34

Torabi SA, Hassini E (2008) An interactive possibilistic programming approach for multiple objective supply chain master planning. Fuzzy Sets Syst 159(2):193–214

Torabi SA, Hassini E (2009) Multi-site production planning integrating procurement and distribution plans in multi-echelon supply chains: an interactive fuzzy goal programming approach. Int J Prod Res 47(19):5475–5499

Tsiakis P, Papageorgiou LG (2008) Optimal production allocation and distribution supply chain networks. Int J Prod Econ 111(2):468–483

van der Vorst JGAJ, Beulens AJM (2002) Identifying sources of uncertainty to generate supply chain redesign strategies. Int J Phys Distrib Logist Manag 32(6):409–430

Vlajic JV, van der Vorst JGAJ, Haijema R (2012) A framework for designing robust food supply chains. Int J Prod Econ 137(1):176–189

Wang W, Fung RYK, Chai Y (2004) Approach of just-in-time distribution requirements planning for supply chain management. Int J Prod Econ 91(2):101–107

Wang F, Lai X, Shi N (2011) A multi-objective optimization for green supply chain network design. Decis Support Syst 51(2):262–269

Wang RC, Liang TF (2005) Applying possibilistic linear programming to aggregate production planning. Int J Prod Econ 98(3):328–341

Zadeh LA (1978) Fuzzy sets as a basis for a theory of possibility. Fuzzy Sets Syst 1(1):3–28

Zanjirani Farahani R, Elahipanah M (2008) A genetic algorithm to optimize the total cost and service level for just-in-time distribution in a supply chain. Int J Prod Econ 111(2):229–243

Zimmermann HJ (1978) Fuzzy programming and linear programming with several objective functions. Fuzzy Sets Syst 1(1):45–55

Zimmermann HJ (1996) Fuzzy set theory and its applications, 3rd edn. Kluwer Academic Publishers, Boston, pp 11–38

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khalili-Damghani, K., Tavana, M. & Amirkhan, M. A fuzzy bi-objective mixed-integer programming method for solving supply chain network design problems under ambiguous and vague conditions. Int J Adv Manuf Technol 73, 1567–1595 (2014). https://doi.org/10.1007/s00170-014-5891-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5891-7