Abstract

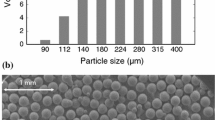

A systematic experimental study has been carried out of two distinct failure phenomena, cavitation and debonding, in an elastomer containing a rigid spherical inclusion. Several elastomers were employed containing glass beads of various diameters, ranging from 60 to 5000 μm, and with chemically different surfaces. The critical stress for cavitation was found to depend upon both Young's modulus, E, of the elastomer and the diameter of the bead. By extrapolation, it was found that the stress for cavitation near an infinitelylarge bead is given by 5E/12, as predicted by theory. In contrast, the critical stress for debonding decreased somewhat with increasing Young's modulus of the elastomer. This is attributed to a concomitant decrease in the strength of adhesion between the elastomer and the bead surface, due to rheological effects. The stresses for both cavitation and for debonding were found to vary approximately with the negative half-power of the bead diameter. This suggests that a similar Griffith mechanism governs both failure processes when the bead size is small. A study of cavitation and debonding in the presence of two glass beads was also carried out. As predicted from theoretical considerations, both stresses were found to decrease as the distance between the two beads was decreased, irrespective of the diameter of the bead and Young's modulus of the elastomer. At higher strains, however, a second cavitation process was found to take place at a point midway between the beads. Tensile fracture of the specimen resulted from the unrestrained lateral growth of the second cavity.

Similar content being viewed by others

References

H. F. Schippel, Industr. Eng. Chem. 12 (1920) 33.

H. A. Depew and M. K. Easley, ibid. 26 (1934) 1187.

C. Markins and H. L. Williams, J. Appl. Polym. Sci. 18 (1974) 21.

A. E. Oberth and R. S. Bruenner, Trans. Soc. Rheol. 9 (1965) 165.

A. N. Gent and P. B. Lindley, Proc. Roy. Soc. (London) A249 (1959) 195.

J. N. Goodier, Trans. ASME 55 (1933) 7.

A. Ahagon and A. N. Gent, J. Polym. Sci. Polym. Phys. Ed. 13 (1975) 1285.

E. O. Hall, Proc. Phys. Soc. (London) 64B (1951) 747.

N. J. Petch, J. Iron Steel Inst. London 174 (1953) 25.

R. A. Sack, Proc. Phys. Soc. (London) 58 (1946) 729.

A. N. Gent and H. J. Kim, Rubber Chem. Technol. 51 (1978) 35.

A. N. Gent, J. Mater. Sci. 15 (1980) 2884.

A. N. Gent and R. P. Petrich, Proc. Roy. Soc. (London) A310 (1969) 433.

A. N. Gent and G. R. Hamed, Plast. Rubber: Mater. Appl. 3 (1978) 17; reprinted in Rubber Chem. Technol. 51 (1978) 354.

Y. M. Ito, M. Rosenblatt, L. Y. Cheng, F. F. Lange and A. G. Evans, Int. J. Fract. 17 (1981) 483.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gent, A.N., Park, B. Failure processes in elastomers at or near a rigid spherical inclusion. J Mater Sci 19, 1947–1956 (1984). https://doi.org/10.1007/BF00550265

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00550265