Abstract

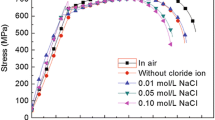

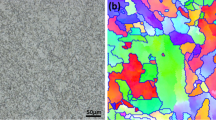

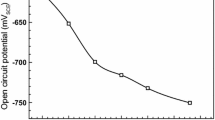

In this study, electrochemical impedance spectroscopy (EIS) simultaneously with the slow strain rate testing were used to investigate the stress corrosion cracking (SCC) behavior of X70 pipeline steel in high pH bicarbonate solution at different applied potentials. Potentiostatic EIS tests were also conducted at certain times to determine the changes associated with the SCC. Circuit models for the cracking were proposed by the use of the potentiostatic EIS measurements at different applied potentials. Finally, the results of the potentiostatic EIS tests and the SSR tests showed the decline of the circuit element resistance by increasing the stress which was related to the cracking. It was also observed that the X70 pipeline steel was most susceptible to SCC at potential of −650 mV versus SCE.

Similar content being viewed by others

References

K. Sibradzki and R.C. Newman, Stress-Corrosion Cracking, J. Phys. Chem. Solids, 1987, 48(11), p 1101–1113

H. Xue and Y. Cheng, Passivity and Pitting Corrosion of X80 Pipeline Steel in Carbonate/Bicarbonate Solution Studied by Electrochemical Measurements, J. Mater. Eng. Perform., 2010, 19(9), p 1311–1317

External Stress Corrosion Cracking of Underground Pipelines, NACE International, October 2003, Item no. 24221

J.T. Bulger, B.T. Lu, and J.L. Luo, Microstructural Effect on Near-Neutral pH Stress Corrosion Cracking Resistance of Pipeline Steels, J. Mater. Sci., 2006, 41(15), p 5001–5005

L. Zhang, X. Li, C. Du, and Y. Huang, Effect of Applied Potentials on Stress Corrosion Cracking of X70 Pipeline Steel in Alkali Solution, Mater. Des., 2009, 30(6), p 2259–2263

V.A. Marichev, One General Rule of Corrosion Cracking of High-Strength Steels, Dokl. Akad. Nauk SSSR, 1974, 218(3), p 638–640

V.A. Marichev, Hydrogen Embrittlement of Construction Materials, Mater. Corros., 1982, 33(1), p 1–14

V.E. Ignatenko, A.I. Marshakov, V.A. Marichev, Yu.N. Mikhailovskii, and N.A. Petrov, Effect of Cathodic Polarization on the Corrosion Cracking Rate in Pipe Steels, Prot. Met., 2000, 36(2), p 111–117

B.N. Leis, R.J. Eiber, Stress Corrosion Cracking on Gas Transmission Pipelines: History, Causes, and Mitigation, 1st Int. Business Conference on Onshore Pipelines, Berlin, 1997

C. Zhang and Y.F. Cheng, Synergistic Effects of Hydrogen and Stress on Corrosion of X100 Pipeline Steel in a Near-Neutral pH Solution, J. Mater. Eng. Perform., 2009, 19(9), p 1284–1289

R.N. Parkins and J.A. Beavers, Some Effects of Strain Rate on the Transgranular Stress Corrosion Cracking of Ferritic Steels in Dilute Near-Neutral-pH Solutions, Corrosion., 2003, 59(3), p 258–273

R.N. Parkins, A Review of Stress Corrosion Cracking in High-Pressure Gas Pipelines, Paper no. 363, Corrosion 2000, NACE, Houston, 2000, Paper no. 363

R.N. Parkins, The Controlling Parameters in Stress Corrosion Cracking, 5th Symposium on Line Pipe Research, November 1974, Arlington, VA, PRCI, 1974, p U-1–U-40

R.R. Fessler, Stress Corrosion Cracking Temperature Effects, 6th Symposium on Line Pipe Research, November 1979, Arlington, VA, PRCI, 1979, p R-1–R-10

J.A. Beavers, C.L. Durr, B.S. Delanty, High-pH SCC: Temperature and Potential Dependence for Cracking in Field Environments, Proceedings of the 3rd International Pipeline Conference, June 1998, New York, NY, ASME, 1998, p 423–437

M.C. Petit, M. Cid, M. Puiggali, and Z. Amor, An Impedance Study of the Passivity Breakdown During Stress Corrosion Cracking Phenomena, Corros. Sci., 1990, 31, p 491–496

M. Keddam, R. Oltra, J.C. Colson, and A. Desestret, Depassivation of Iron by Straining and by Abrasion: An A.C. Impedance Study, Corros. Sci., 1983, 23(4), p 441–451

K. Darowicki, J. Orlikowski, and A. Arutunow, Investigations of the Passive Layer Cracking by Means of Dynamic Electrochemical Impedance Spectroscopy, Electrochim. Acta, 2003, 48(28), p 4189–4196

K. Darowicki, J. Orlikowski, and A. Arutunow, Dynamic Electrochemical Impedance Spectroscopy Measurements of Passive Layer Cracking Under Static Tensile Stresses, J. Solid State Electrochem., 2004, 8(6), p 352–359

R.W. Bosch, Electrochemical Impedance Spectroscopy for the Detection of Stress Corrosion Cracks in Aqueous Corrosion Systems at Ambient and High Temperature, Corros. Sci., 2005, 47(1), p 125–143

M. Touzet, M. Puiggali, M. Cid, and D. Desjardins, The Characterization of Damage in SCC by an Electrochemical Impedance and Statistical Study of Multiple Cracking, Corros. Sci., 1994, 36(5), p 815–821

R. de Levie, Advances in Electrochemistry and Electrochemical Engineering, Vol 6, Wiley, New York, 1967, p 329–398

X. Lou and P.M. Singh, Phase Angle Analysis for Stress Corrosion Cracking of Carbon Steel in Fuel-Grade Ethanol: Experiments and Simulation, Electrochim. Acta, 2011, 56(4), p 1835–1847

“Slow Strain Rate Test Method for Screening Corrosion-Resistant Alloys for Stress Corrosion Cracking in Sour Oilfield Service”, TM0198-2004, NACE Standard, Item No. 21232

R.N. Parkins, C.S. O’Dell, and R.R. Fessler, Factors Affecting the Potential of Galvanostatically Polarised Pipeline Steel in Relation to SCC in CO3 2−-HCO3− Solutions, Corros. Sci., 1984, 24(4), p 343–374

R.N. Parkins and S. Zhou, The Stress Corrosion Cracking of C-Mn Steel in CO3 2−-HCO3− Solutions. II: Electrochemical and Other Data, Corros. Sci., 1997, 39(1), p 175–191

H. Keiser, K.D. Beccu, and M.A. Gutjahr, Abschätzung der Porenstruktur Poröser Elektroden aus Impedanzmessungen, Electrochim. Acta, 1976, 21(8), p 539–543 (in German)

E. Barsoukov and J.R. Macdonald, Impedance Spectroscopy Theory, Experiment and Applications, Wiley-Interscience, Hoboken, NJ, 2005

A.A. Oskuie, T. Shahrabi, A. Shahriari, and E. Saebnoori, Electrochemical Impedance Spectroscopy Analysis of X70 Pipeline steel Stress Corrosion Cracking in High pH Carbonate Solution, Corros. Sci., 2012, 61, p 111–122

W.R. Osório, C. Brito, L.C. Peixoto, and A. Garcia, Electrochemical Behavior of Zn-rich Zn-Cu Peritectic Alloys Affected by Macrosegregation and Microstructural Array, Electrochim. Acta, 2012, 76, p 218–228

H.L. Li, K.W. Gao, L.J. Qiao, Y.B. Wang, and W.Y. Chu, Strength Effect in Stress Corrosion Cracking of High-Strength Steel in Aqueous Solution, Corrosion, 2001, 57(4), p 295–299

M.C. Fatah, M.C. Ismail, B. Ari-Wahjoedi, Electrochemical Behavior of X52 Steel in a CO2 Environment in the Presence of Acetate and Sulfide, J. Mater. Eng. Perform, 2012, doi:10.1007/s11665-012-0211-6

W.R. Osorio, J.E. Spinelli, C.R.M. Afonso, L.C. Peixoto, and A. Garcia, Microstructure, Corrosion Behaviour and Microhardness of a Directionally Solidified Sn-Cu Solder Alloy, Electrochim. Acta, 2011, 56, p 8891–8899

W.R. Osorio, D.J. Moutinho, L.C. Peixoto, I.L. Ferreira, and A. Garcia, Macrosegregation and Microstructure Dendritic Array Affecting the Electrochemical Behaviour of Ternary Al-Cu-Si Alloys, Electrochim. Acta, 2011, 56(24), p 8412–8421

F.M. Song, Predicting the Mechanisms and Crack Growth Rates of Pipelines Undergoing Stress Corrosion Cracking at High pH, Corros. Sci., 2009, 51(11), p 2657–2674

R.N. Parkins, E. Belhimer, and W.K. Blanchard, Jr., Stress Corrosion Cracking Characteristics of a Range of Pipeline Steels in Carbonate-Bicarbonate Solution, Corrosion, 1993, 49(12), p 951–966

D. Hardie and E.A. Charles, Hydrogen Embrittlement of High Strength Pipeline Steels, Corros. Sci., 2006, 48(12), p 4378–4385

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shahriari, A., Shahrabi, T. & Oskuie, A.A. A Study on Stress Corrosion Cracking of X70 Pipeline Steel in Carbonate Solution by EIS. J. of Materi Eng and Perform 22, 1459–1470 (2013). https://doi.org/10.1007/s11665-012-0418-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0418-6