Abstract

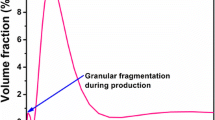

This work investigates the effect of excipient particle size on compaction properties of brittle, plastic and viscoelastic materials with and without added lubricants. Sieve cuts of Microcrystalline cellulose (MCC), Starch and Dibasic calcium phosphate dihydrate were obtained by sieving, then samples were tested without lubrication or with added lubricant (0.5% Mg stearate mixed for either 5 or 30-min). Compacts were left overnight before testing. It was found that in the absence of lubricant, compact tensile strength (TS) was dependent on particle size only for starch. With Mg stearate, lubricant sensitivity shows a strong dependence on excipient particle size for both starch and MCC, where smaller particles are less affected by lubricant. Dibasic calcium phosphate dihydrate was not sensitive to lubricant even after 30 min mixing. This study highlights that in the absence of lubricant, initial particle size of excipients has no impact on compact strength not only for Dibasic calcium phosphate dihydrate (brittle), but also for MCC (plastic). On the other hand, TS is dependent on particle size both with or without added lubricant for starch (viscoelastic).

Similar content being viewed by others

References

G. Moody, M. H. Rubinstein, and R. A. FitzSimmons. Tablet lubricants I. Theory and modes of action. Int. J. Pharm. 9:75–80 (1981).

G. K. Bolhuis, and A. W. Holzer. Lubricant sensitivity. In G. Alderborn, and C. Nystrom (eds.), Pharmaceutical Powder Compaction Technology, Marcel Dekker, New York, NY, USA, 1996, pp. 517–560.

G. K. Bolhuis, C. F. Lerk, H. T. Zijlstra, and A. H. De Boer. Film formation by magnesium stearate during mixing and its effect on tabletting. Pharm. Weekbl. 110:317–325 (1975).

V. Swaminathan, J. Cobb, and I. Saracovan. Measurement of the surface energy of lubricated pharmaceutical powders by inverse gas chromatography. Int. J. Pharm. 312:158–165 (2006).

A. H. De Boer, G. K. Bolhuis, and C. F. Lerk. Bonding characteristics by scanning electron microscopy of powders mixed with magnesium stearate. Powder Tech. 20:75–82 (1978).

L. Roblot-Treupel, and F. Puisieux. Distribution of magnesium stearate on the surface of lubricated particles. Int. J. Pharm. 31:131–136 (1986).

M. S. Hussain, P. York, P. Timmins, and P. Humphrey. Secondary ion mass spectrometry (SIMS) evaluation of magnesium stearate distribution and its effects on the physico-technical properties of sodium chloride tablets. Powder Tech. 60:39–45 (1990).

C. F. Lerk, G. K. Bolhuis, and S. S. Smedema. Interaction of lubricants and colloidal silica during mixing with excipients. Pharm. Acta Helv. 52:33–39 (1977).

X. He, P. Secreast, and G. Amidon. Mechanistic study of the effect of roller compaction and lubricant on tablet mechanical strength. J. Pharm. Sci. 5:1342–1355 (2007).

A. Mehrotra, M. Llusa, A. Faqih, M. Levin, and F. Muzzio. Influence of shear intensity and total shear on properties of blends and tablets of lactose and cellulose lubricated with magnesium stearate. Int. J. Pharm. 336:284–291 (2007).

H. Vromans, and C. F. Lerk. Densification properties and compactibility of mixtures pharmaceutical excipients with and without magnesium stearate. Int. J. Pharm. 46:183–192 (1988).

H. Vromans, G. K. Bolhuis, and C. F. Lerk. Magnesium stearate susceptibility of directly compressible materials as an indication of fragmentation properties. Powder Tech. 54:39–44 (1988).

M. Eriksson, and G. Alderborn. The effect of particle fragmentation and deformation on the interparticulate bond formation process during powder compaction. Pharm. Res. 13:1031–1039 (1995).

D. E. Wurster, S. Likitlersuang, and Y. Chen. The influence of magnesium stearate on the Hiestand Tableting Indices and other related mechanical properties of maltodextrins. Pharm. Dev. Technol. 10:461–466 (2005).

J. G. Van Der Watt. The effect of the particle size of microcrystalline cellulose on tablet properties in mixtures with magnesium stearate. Int. J. Pharm. 36:51–54 (1987).

C. E. Bos, G. K. Bolhuis, H. van Doorne, and C. F. Lerk. Native starch in tablet formulations: properties on compaction. Pharm. Weekbl. Sci. Ed. 9:274–282 (1987).

K. Zuurman, V. V. Maarschalk, and G. K. Bolhuis. Effect of magnesium stearate on bonding and porosity expansion of tablets produced from materials with different consolidation properties. Int. J. Pharm. 179:107–115 (1999).

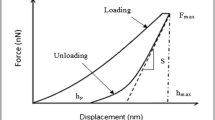

A. Aburub, I. Buckner, and D. Mishra. Utilization of compaction energetics for understanding particle deformation mechanism. Pharm. Dev. Technol. 12:405–414 (2007).

M. Whiteman, and R. J. Yarwood. Variations in the properties of microcrystalline cellulose form different sources. Powder Tech. 54:71–74 (1988).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Almaya, A., Aburub, A. Effect of Particle Size on Compaction of Materials with Different Deformation Mechanisms with and without Lubricants. AAPS PharmSciTech 9, 414–418 (2008). https://doi.org/10.1208/s12249-008-9059-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-008-9059-3