Abstract

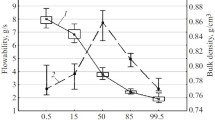

The aim of this study was to analyze the process of tablet formation and the properties of the resulting tablets for 3 N-deacetylated chitosans, with a degree of deacetylation of 80%, 85%, or 90%. Material properties, such as water content, particle size and morphology, glass transition temperature, and molecular weight were studied. The process of tablet formation was analyzed by 3-D modeling, Heckel analysis, the pressure time function, and energy calculations in combination with elastic recovery dependent on maximum relative density and time. The crushing force and the morphology of the final tablets were analyzed. Chitosans sorb twice as much water as microcrystalline cellulose (MCC), the particle size is comparable to Avicel PH 200, a special type of MCC, the particles look like shells, and the edges are bent. Molecular weight ranges from 80 000 to 210 000 kDa, the glass transition temperature (Tg) was not dependent on molecular weight. The chitosans deform ductilely as MCC; however, plastic deformation with regard to time and also pressure plasticity are higher than for MCC, especially for Chit 85, which has the lowest crystallinity and molecular weight. At high densification, fast elastic decompression is higher. 3-D modeling allowed the most precise analysis. Elastic recovery after tableting is higher than for MCC tablets and continues for some time after tableting. The crushing force of the resulting tablets is high owing to a reversible exceeding of Tg in the amorphous parts of the material. However, the crushing force is lower compared with MCC, since the crystallinity and the Tg of the chitosans are higher than for MCC. In summation, chitosans show plastic deformation during compression combined with high elasticity after tableting. Highly mechanically stable tablets result.

Similar content being viewed by others

References

Hudson SM, Smith C. Polysaccharides: chitin and chitosan: chemistry and technology of their use as structural materials. In: Kaplan DL, ed.Biopolymers From Renewable Sources. Berlin, Germany: Springer; 1998:96–118.

Hirano S. Chitin and chitosan.Ullmann’s Encyclopedia of Industrial Chemistry [book on CD-ROM], New York, NY: John Wiley & Sons Inc.; 2000.

Pavlath AE, Wong DWS, Robertson GH. Chitosan (preparation, structure, and properties). In: Salamone JC, ed.Polymeric Materials Encyclopedia [Book on CD-ROM]. Boca Raton, FL: CRC Press Inc; 1996.

van Luyen D, Mai Huong D. Chitin and derivatives. In: Salomone JC, ed.Polymeric Materials Encyclopedia [Book on CD-ROM]. Boca Raton, FL: CRC Press Inc; 1996.

Felt O, Buri P, Gurny R. Chitosan: a unique polysaccharide for drug delivery.Drug Dev Ind Pharm. 1998;24:979–993.

Genta I, Perugini P, Pavanetto F. Different molecular weight chitosan microspheres: influence on drug loading and drug release.Drug Dev Ind Pharm. 1998;24:779–784.

Illum L. Chitosan and its use as a pharmaceutical excipient.Pharm Res. 1998;15:1326–1331.

He P, Davis SS, Illum L. Sustained release chitosan microspheres prepared by novel spray drying methods.J Microencapsul. 1999; 16:343–355.

Lueßen HL, Rentel CO, Kotzé AF, et al. Mucoadhesive polymers in peroral peptide drug delivery. IV. Polycarbophil and chitosan are potent enhancers of peptide transport across intestinal mucosae in vitro.J Control Release. 1997;45:15–23.

Paul W, Sharma CP. Chitosan, a drug carrier for the 21st century: a review.STP Pharma Sci. 2000;10:5–22.

Remunan-López C, Portero A, Vila-Jato JL, Alonso MJ. Design and evaluation of chitosan/ethylcellulose mucoadhesive bilayered devices for buccal drug delivery.J Control Release. 1998;55:143–152.

Yamamoto H, Takeuchi H, Hino TK, Kawashima Y. Mucoadhesive liposomes: physicochemical properties and release behavior of water-soluble drugs from chitosan-coated liposomes.STP Pharma Sci. 2000;10:63–68.

Sawayanagi Y, Nambu N, Nagai T. Directly compressed tablets containing chitin or chitosan in addition to lactose or potato starch.Chem Pharm Bull (Tokyo). 1982;30:2935–2940.

Sawayanagi Y, Nambu N, Nagai T. Directly compressed tablets containing chitin or chitosan in addition to mannitol.Chem Pharm Bull (Tokyo). 1982;30:4216–4218.

Knapczyk J. Excipient ability of chitosan for direct tableting.Int J Pharm. 1993;89:1–7.

Yao T, Yamada M, Yamahara H, Yoshida M. Tableting of coated particles. II. Influence of particle size of pharmaceutical additives on the protection of coating membrane from mechanical damage during compression process.Chem Pharm Bull (Tokyo). 1998;46:1510–1514.

Sawayanagi Y, Nambu N, Nagai T. Use of chitosan for sustained-release preparations of water-soluble drugs.Chem Pharm Bull (Tokyo). 1982;30:4213–4215.

Henriksen I, Skaugrud O, Karlsen J. Use of chitosan and chitosan malate as an excipient in wet granulation of three water soluble drugs.Int J Pharm. 1993;98:181–188.

Rege PR, Shukla DJ, Block LH. Chitinosans as tableting excipients for modified release delivery systems.Int J Pharm. 1999;181:49–60.

Picker KM. Soft tableting: a new concept to tablet pressure sensitive drugs.Pharm Dev Technol. 2004;9:107–121.

Anthonsen MW, Vårum KM, Hermansson AM, Smidsrød O, Brant DA. Aggregates in acidic solutions of chitosans detected by static laser light scattering.Carbohydr Polym. 1994;25:13–23.

Beri RG, Walker J, Reese ET, Rollings JE. Characterization of chitosans via coupled size-exclusion chromatography and multi-angle laser light-scattering technique.Carbohydr Res. 1993;238:11–26.

Greenspan L. Humidity fixed points of binary saturated aqueous solutions.J Res Natl Bureau Stand-A Phys Chem. 1977;81:89–96.

Picker KM, Mielck JB. True density of swellable substances at different relative humidities: a new approach to its determination.Eur J Pharm Biopharm. 1996;42:82–84.

Carr RL. Evaluating flow properties of solids.Chem Eng. 1965;72:163–168.

Picker KM. The relevance of glass transition temperature for the process of tablet formation.J Therm Anal Calorim. 2003;73:597–605.

Picker KM. New Insights Into the Process of Tablet Formation—Ways to Explore Soft Tableting.Habilitationsschrift Universität Halle-Wittenberg. Marburg, Germany: Görich und Weiershäuser Verlag: 2002.

Heckel RW. An analysis of powder compaction phenomena.Trans Metallurg Soc AIME. 1961;221:1001–1008.

Picker KM. A new theoretical model to characterize the densification behavior of tableting materials.Eur J Pharm Biopharm. 2000;49:267–273.

Dietrich R, Mielck JB. Parametrisierung des zeitlichen Verlaufs der Verdichtung bei der Tablettierung mit Hilfe der modifizierten Weibull-FunktionPharm Ind. 1985;47:216–220.

Konkel P, Mielck JB. Associations of parameters characterizing the time course of the tableting process on a reciprocating and on a rotary tableting machine for high-speed production.Eur J Pharm Biopharm. 1998;45:137–148.

Dürr M, Hanssen D, Harwalik H. Kennzahlen zur Beurteilung der Verpreßbarkeit von Pulvern und Granulaten.Pharm Ind. 1972;34:905–911.

Armstrong NA, Haines-Nutt RF. Elastic recovery and surface area changes in compacted powder systems.J Pharm Pharmacol. 1972; 24:135P-136P.

Picker KM. Time dependence of elastic recovery for characterization of tableting materials.Pharm Dev Technol. 2001;6:61–70.

Mo X, Tu T, Zhou H. Crystallization kinetics of chitosan.Gonneng Gaofenzzi Xuebao. 1996;9:102–112.

Saleki-Gerhardt A, Ahlneck C, Zografi G. Assessment of disorder in crystalline solids.Int J Pharm. 1994;101:237–247.

Schmidt J.Direkttablettierung niedrigschmelzender nichtsteroidaler Antirheumatika mit mikrokristallinen Cellulosen [dissertation]. Halle/Saale, Germany Universität Halle-Wittenberg; 1997.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published: September 8, 2006

Rights and permissions

About this article

Cite this article

Picker-Freyer, K.M., Brink, D. Evaluation of powder and tableting properties of chitosan. AAPS PharmSciTech 7, 75 (2006). https://doi.org/10.1208/pt070375

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/pt070375