Abstract

TEM measurements are used to experimentally study thermoelastic martensite transformation in Ti2NiCu tapered plates. The martensite phase is observed at room temperature in the Ti2NiCu alloy when the plate thickness decreases to, at least, 80 nm, and the austenite phase is observed at smaller thicknesses. It is shown that the temperature of thermoelastic martensite transition in the Ti2NiCu alloy decreases with a decrease in the thickness of the plate, the transition is blocked at a thickness of less than 20 nm, and a hysteresis dependence is observed. Possible physical and technological reasons for blocking of the martensite phase transition on nanoscale and fundamental limitations on the sizes of micromechanical devices based on the shape-memory Ti2NiCu alloy are considered.

Similar content being viewed by others

References

G. V. Kurdyumov and L. G. Khandros, Dokl. Akad. Nauk SSSR 66, 211 (1949).

I. E. Dikshten, D. I. Ermakov, V. V. Koledov, L. V. Koledov, T. Takagi, A. A. Tulakova, A. A. Cherechukin, and V. G. Shavrov, JETP Lett. 72, 373 (2000).

V. N. Khachin, V. G. Pushin, and V. V. Kondrat’ev, Structure and Properties (Nauka, Moscow, 1992), p. 160 [in Russian].

A. A. Cherechukin, I. E. Dikshtein, D. I. Ermakov, et al., Phys. Lett. A 291, 175 (2000).

G. A. Malygin, Tech. Phys. 54, 1782 (2009).

C. Kexel, S. Schramm, and V. Solov’yov, Eur. Phys. J. 88, 221 (2015).

S. Kajiwara, S. Ohno, and K. Honma, Philos. Mag. 63, 625 (1991).

A. M. Glezer, E. N. Blinova, V. A. Pozdnyakov, and A. V. Shelyakov, J. Nanoparticle Res. 5, 551 (2003).

Juan J. M. San, M. L. Nó, and C. A. Schuh, Adv. Mater. 20, 272 (2008).

H. Ghassemi-Armaki, A. C. Leff, M. L. Taheri, et al., Acta Mater. 136, 134 (2017).

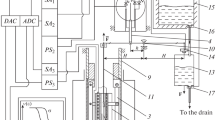

A. V. Irzhak, V. S. Kalashnikov, V. V. Koledov, D. S. Kuchin, G. A. Lebedev, P. V. Lega, N. A. Pikhtin, I. S. Tarasov, V. G. Shavrov, and A. V. Shelyakov, Tech. Phys. Lett. 36, 329 (2010).

A. V. Irzhak, D. I. Zakharov, V. S. Kalashnikov, V. V. Koledov, D. S. Kuchin, G. A. Lebedev, P. V. Lega, E. P. Perov, N. A. Pikhtin, V. G. Pushin, I. S. Tarasov, V. V. Khovailo, V. G. Shavrov, and A. V. Shelyakov, J. Commun. Technol. Electron. 55, 818 (2010).

A. V. Shelyakov, N. N. Sitnikov, V. V. Koledov, et al., Int. J. Smart & Nano Mater. 2, 68 (2011).

P. V. Lega, V. V. Koledov, A. P. Orlov, D. S. Kuchin, et al., Adv. Eng. Mater. 19 (8), 1700154 (2017).

A. V. Irzhak, P. V. Lega, A. M. Zhikharev, V. V. Koledov, A. P. Orlov, D. S. Kuchin, N. Yu. Tabachkova, V. A. Dikan, A. V. Shelyakov, M. Yu. Beresin, V. G. Pushin, S. V. von Gratowski, V. Ya.Pokrovskiy, S. G. Zybtsev and V. G. Shavrov, Dokl. Phys. 62, 5 (2017).

N. M. Matveeva, V. G. Pushin, A. V. Shelyakov, et al., Fiz. Met. Metallogr. (FMM) 83 (6), 82 (1997).

S. C. Mao, H. X. Li, Y. Liu, et al., J. All. Comp. 579, 100 (2013).

S. Gur and G. N. Frantziskonis, Smart Mater. Res., 7512642 (2016).

B. T. H. Nam, T. Saburi, Y. Nakata, and K. Shimizu, Mater. Trans. 31, 1050 (1990).

G. Pan, Z. Cao, M. Wei, and J. Shi, Mater. Lett. 130, 285 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © P.V. Lega, V.V. Koledov, N.Yu. Tabachkova, A.V. Irzhak, A.V. Shelayakov, D.S. Kuchin, A.P. Orlov, V.G. Shavrov, 2018, published in Radiotekhnika i Elektronika, 2018, Vol. 63, No. 5, pp. 463–470.

Rights and permissions

About this article

Cite this article

Lega, P.V., Koledov, V.V., Tabachkova, N.Y. et al. Fundamental Limitations on Miniaturization of Shape-Memory Micromechanical Devices. Thermoelastic Martensite Transformation on Micro-, Nano-, and Mesoscales. J. Commun. Technol. Electron. 63, 468–475 (2018). https://doi.org/10.1134/S1064226918050066

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1064226918050066